Surface well-downhole long borehole fracturing coal seam method

A long drilling and coal seam technology, applied in the field of fracturing coal seams, can solve the problems of small fracturing range, low fracturing pressure, inability to realize large-scale, high-pressure fracturing, etc., and achieve wide fracturing range and increased pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

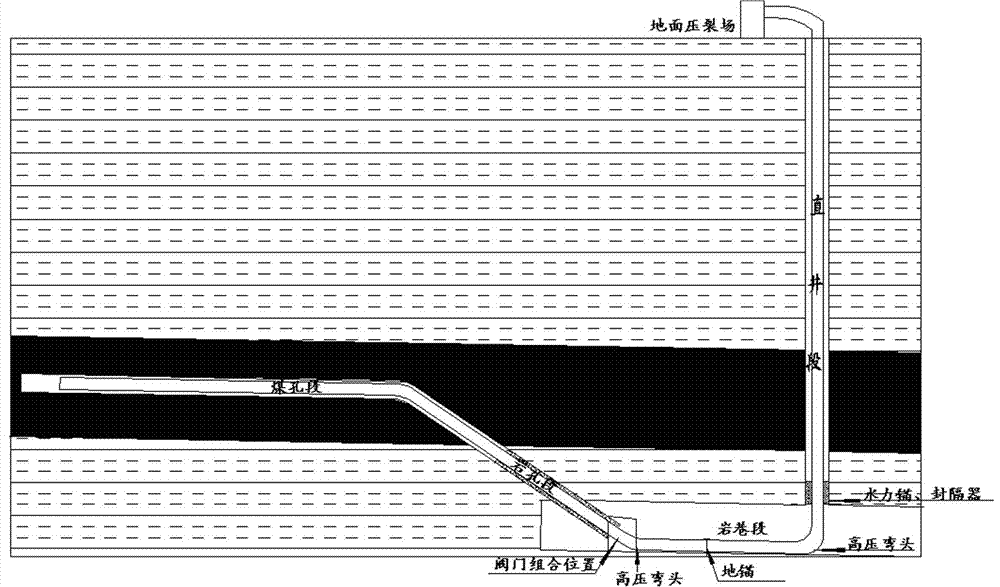

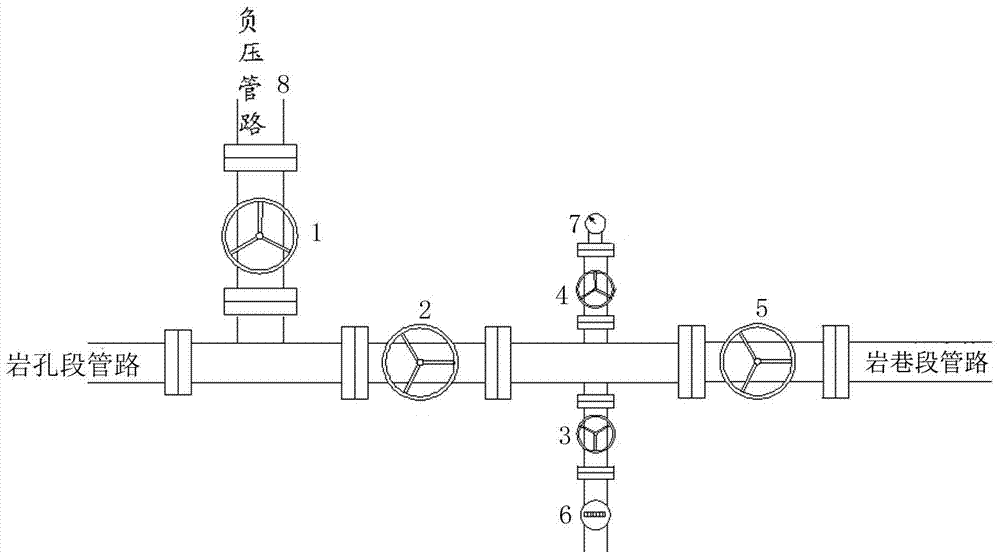

[0015] The basic structure of surface well-downhole long hole fracturing coal seam method is as follows figure 1 As shown, the high-pressure fracturing pipeline system is formed by connecting the fracturing equipment on the surface well site, the vertical well section, the rock roadway section, and the long downhole borehole through the high-pressure fracturing pipeline. The length of the coal hole is greater than or equal to 100m.

[0016] In terms of pipeline selection: high-pressure resistant pipelines (≤45MPa) are used for high-pressure fracturing fluid transportation in the vertical well section, rock roadway section, and rock hole section; glass fiber reinforced plastic screen pipes and PE with good toughness are used for pipelines in the coal hole section. Screen tubes, screen tubes can not only fix holes in coal seams but also promote uniform fracturing of coal seams.

[0017] In terms of pipeline fixing: In order to prevent the pipeline from shaking during high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com