Low-pressure steam turboset with 360-degree volute casing admission low-pressure inner cylinder

A steam turbine unit, low pressure technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unfavorable downstream flow, large steam vortex, uneven outlet, etc., to achieve good flow characteristics, improved economy, and reduced Effect of steam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

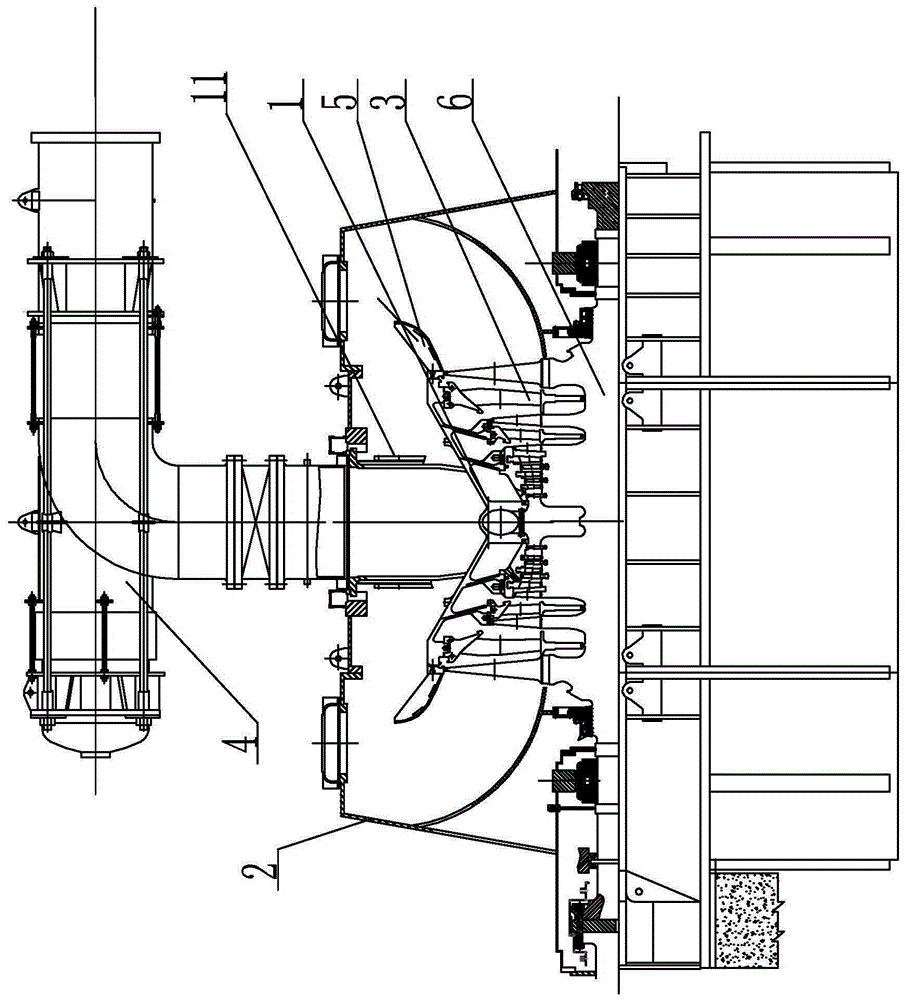

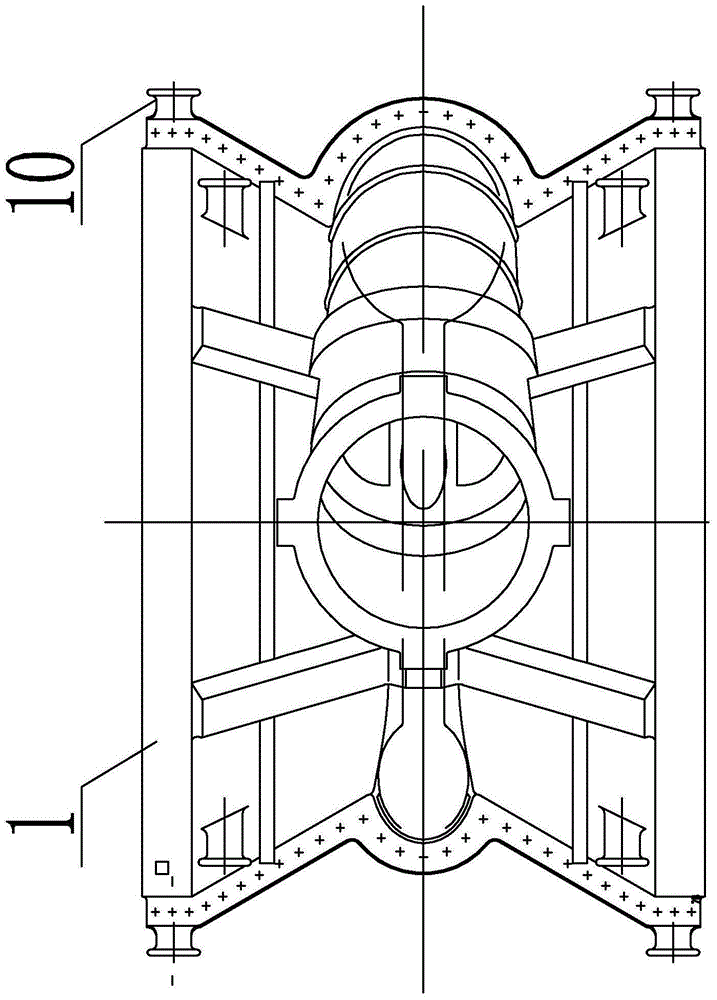

[0012] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, a low-pressure steam turbine unit with a 360° volute intake low-pressure inner cylinder described in this embodiment, which includes a 360° volute intake low-pressure inner cylinder 1, a low-pressure outer cylinder 2, and multi-stage baffles Component 3, steam inlet connecting pipe 4, low-pressure exhaust guide ring 5 and rotor 6; steam inlet connecting pipe 4 is installed on the low-pressure outer cylinder 2, and the 360° volute intake low-pressure inner cylinder 1 is set in the low-pressure outer cylinder 2 , the low-pressure exhaust guide ring 5 is installed on the 360° volute intake low-pressure inner cylinder 1, the multi-stage baffle assembly 3 is installed in the cavity of the 360° volute intake low-pressure inner cylinder 1, and the 360° volute intake The low-pressure inner cylinder 1 is sleeved on the rotor 6, and the steam inlet communication pipe 4 passes through the low-pr...

specific Embodiment approach 2

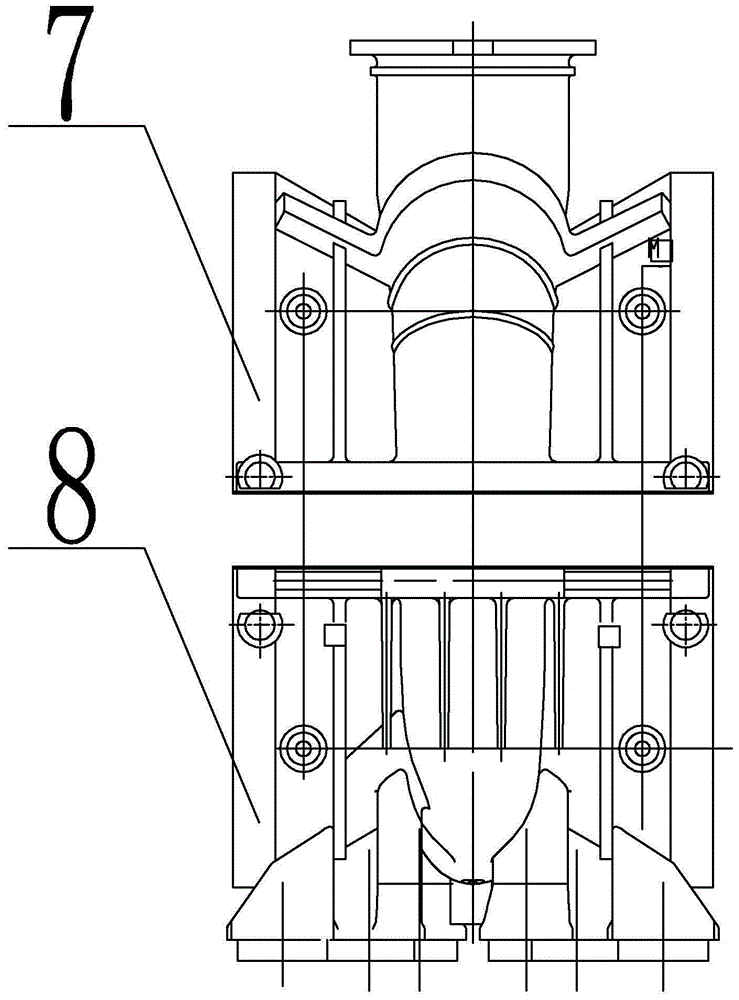

[0013] Specific implementation mode two: combination Figure 1-Figure 5 Describe this embodiment, a low-pressure steam turbine unit with a 360° volute intake low-pressure inner cylinder described in this embodiment, the 360° volute intake low-pressure inner cylinder 1 includes an upper casing 7 and a lower casing 8. The upper shell 7 and the lower shell 8 are relatively buckled to form a closed annular cavity. The upper shell 7 is provided with an upper shell air inlet, and the upper shell 7 is provided with an upper shell air intake and an upper shell. The casing 7 and the lower casing 8 form a closed annular cavity that is sealed and communicated. The upper casing inlet pipe port on the upper casing 7 passes through the casing of the low-pressure outer cylinder 2 and is connected with the steam inlet communication pipe 4. Others are related to the specific implementation. Method 1 is the same.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 4 Describe this embodiment, a low-pressure steam turbine unit with a 360° volute intake low-pressure inner cylinder described in this embodiment, the 360° volute intake low-pressure inner cylinder 1 also includes two steam flow baffles 9, The steam flow baffle 9 is an arc-shaped plate, the upper casing 7 is provided with a steam flow baffle 9, and the lower casing 8 is provided with a steam flow baffle 9, and the steam flow baffle 9 plays a role in diverting the steam flow , so that the steam flow in the volute more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com