Blue photo-sensitive resin composition, color filter manufactured using same, and image display device

A resin composition, blue photosensitive technology, applied in photosensitive materials, instruments, optics, etc. for optomechanical equipment, can solve the problems of unsolved VD spots, stitch spots, etc., and achieve poor display improvement, excellent viewing angle, flow Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] Hereinafter, in order to specifically describe this specification, an embodiment is taken as an example for detailed description. However, the examples in this specification can be modified into other various forms, and it should not be construed that the scope of this specification is limited to the examples described in detail below. The embodiments of this specification are provided to more completely explain this specification to those skilled in the art. In addition, below, "%" and "part" which show content are weight basis unless there is mention in particular.

preparation example 1

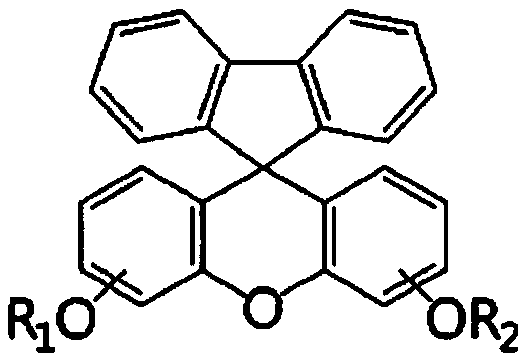

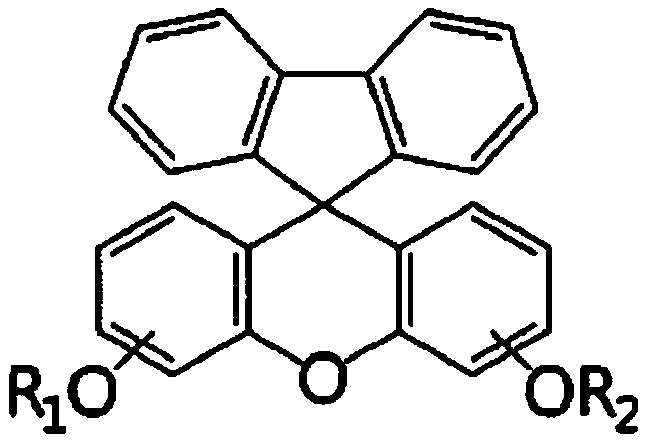

[0117] Preparation Example 1: Synthesis of Compounds of Chemical Formula 1-1-1

[0118] Mix 3', 6'-dihydroxyspiro (fluorene-9,9'-xanthene) (3', 6''-dihydroxyspiro (fluorene-9, 9-xantene) 364.4g and 0.4159g of tert-butyl ammonium bromide, and after adding 2359g of epichlorohydrin, heat to 90°C and make it react. Analyze by liquid chromatography, if 3',6'-dihydroxyspiro (fluorene-9,9'- Xanthene) is completely consumed, then cooled to 30 ° C, slowly added 50% NaOH aqueous solution (3 equivalents). Analyze by liquid chromatography, if epichlorohydrin is completely consumed, then use dichloromethane to extract and wash 3 times, Then, dichloromethane was distilled under reduced pressure after drying the organic layer with magnesium sulfate, and recrystallization was performed using dichloromethane and methanol at a mixing ratio of 50:50.

[0119] After mixing 1 equivalent of epoxy compound thus synthesized, 0.004 equivalent of tert-butylammonium bromide, 0.001 equivalent of 2,6-dii...

preparation example 2

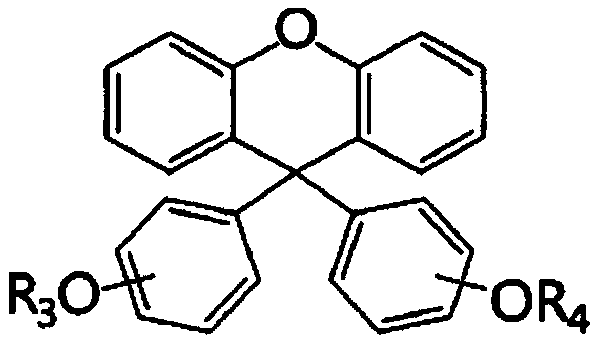

[0122] Preparation Example 2: Synthesis of Cardo-based Binder Resin (C-1)

[0123] After adding 600 g of propylene glycol monomethyl ether acetate to 307.0 g of the compound of chemical formula 1-1-1 of Preparation Example 1 and dissolving it, 78 g of biphenyltetracarboxylic dianhydride and 1 g of tetraethylammonium bromide were mixed. , make it warm up slowly and react at 110-115° C. for 4 hours. After confirming that the acid anhydride group disappeared, 38.0 g of 1,2,3,6-tetrahydrophthalic anhydride was mixed, reacted at 90° C. for 6 hours, and polymerized into a Cardo-based binder resin. The disappearance of the anhydrate was confirmed by IR spectrum. The weight average molecular weight was 3500.

[0124] Device: HLC-8120GPC (manufactured by Tosoh Corporation)

[0125] Column: TSK-GELG4000HXL+TSK-GELG2000HXL (connected in series)

[0126] Column temperature: 40°C

[0127] Mobile phase solvent: tetrahydrofuran

[0128] Flow rate: 1.0mL / min

[0129] Injection volume: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com