Valve rocker arm assembly and engine same

A valve rocker arm and assembly technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing the processing cost of the cylinder head, complex structure of the rocker seat, and many parts, so as to reduce the processing cost and simplify the process. Structure, the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

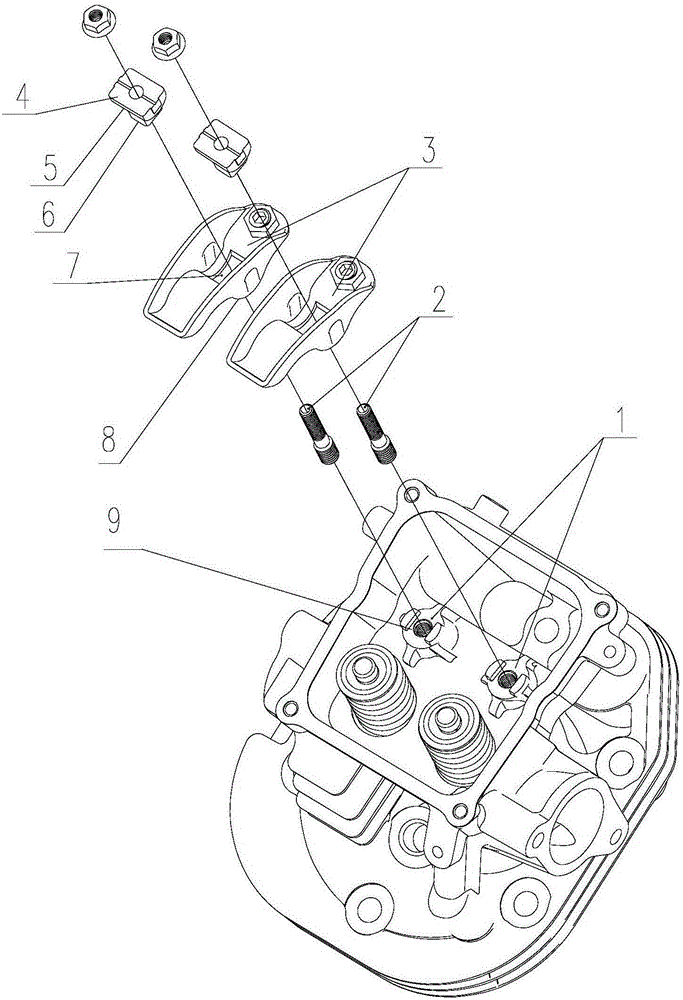

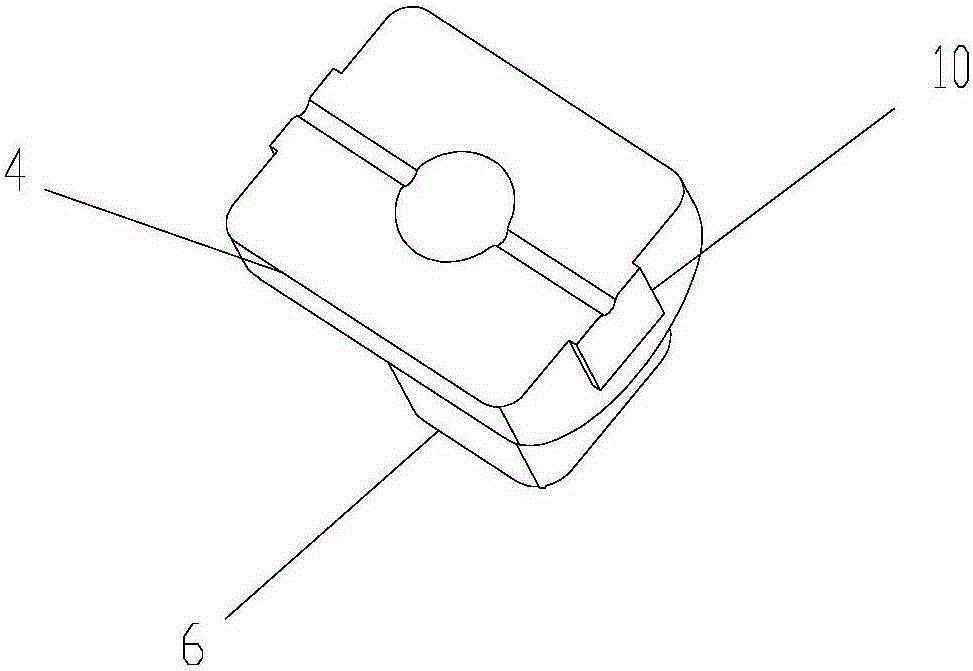

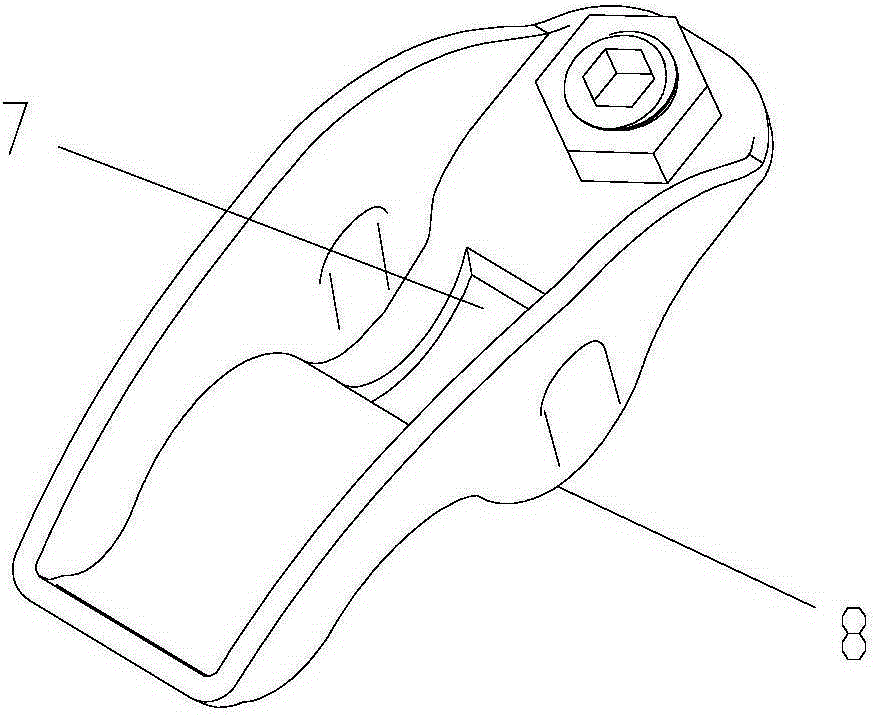

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the limiting block of the present invention, image 3 It is a structural schematic diagram of the rocker arm of the present invention; Figure 4 It is a structural schematic diagram of the rocker arm seat of the present invention. As shown in the figure, the valve rocker arm assembly of this embodiment includes a rocker arm seat 1 and a rocker arm 3; the rocker arm 3 is supported on the rocker arm seat 1 and forms a The rocker arm 3 is a matching pair that swings relative to the rocker arm seat 1. The rocker arm 3 is provided with a limit block 5 that makes it swing and cooperate with the rocker arm seat 1 in a single degree of freedom. The rocker arm 3 can swing through the matching pair. It is directly supported on the rocker arm base 1, so there is no need to use rocker shafts and other parts to rotatably connect the rocker arm 3 to the rocker a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap