Flow enlarging valve and hydraulic steering system

A flow amplification and throttle valve technology, applied in the direction of fluid steering mechanism, fluid pressure actuating device, servo motor assembly, etc., can solve the problems of large hydraulic energy loss, large hydraulic energy loss and large hydraulic shock of flow amplification valve, etc. Achieve the effect of reducing energy loss, saving energy and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation will be described below in conjunction with the accompanying drawings.

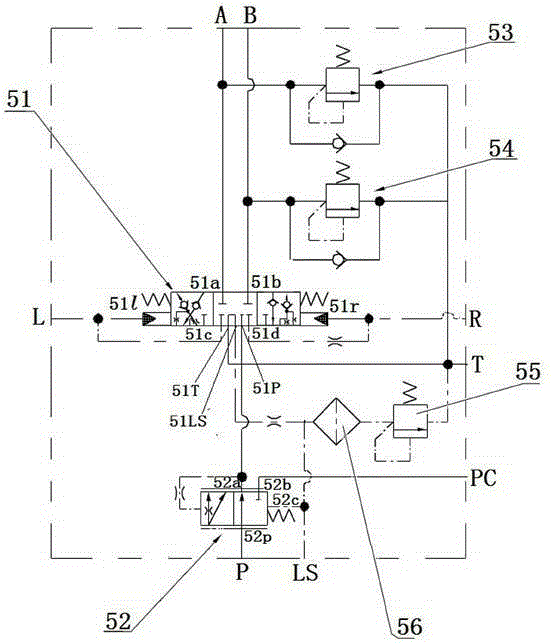

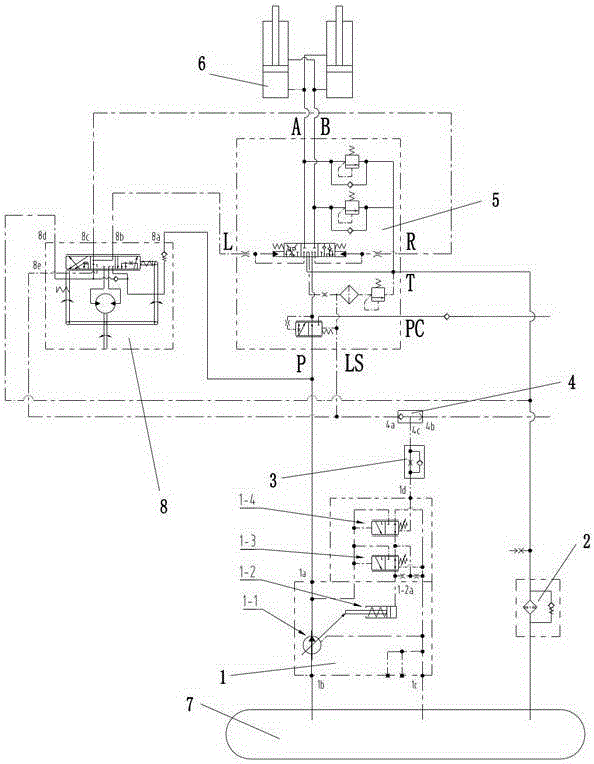

[0021] Such as figure 1 As shown, the flow amplifying valve in this embodiment is provided with P oil port, T oil port, A oil port, B oil port, L oil port, R oil port, LS oil port, PC oil port and PC oil port connected to the reversing valve. Port, which includes a reversing valve 51, a two-position three-way valve 52, a left oil supply valve 53, a right oil supply valve 54, an overflow valve 55, a filter 56, and the oil inlet of the two-position three-way valve 52 It is connected with the P oil port, one oil outlet 52a of the two-position three-way valve is connected with the oil inlet port of the reversing valve, and the other oil outlet 52b of the two-position three-way valve 52 is connected with the PC oil port, and the two-position three-way The spring control chamber 52c of the valve 52 communicates with the LS oil port, and the control chamber on the other side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com