Flue gas treatment device for domestic refuse incineration

A technology for domestic waste incineration and flue gas treatment, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as failure to achieve long-term stable emission standards, the system cannot operate normally, and the gas has high moisture content, and achieves safe use, Reasonable design and the effect of reducing the footprint of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

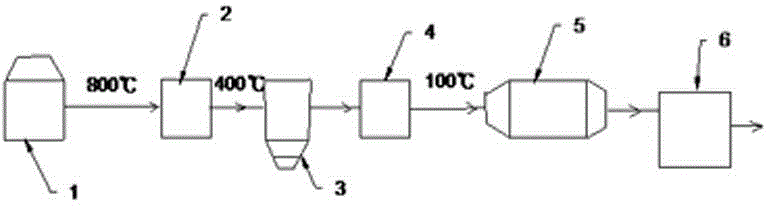

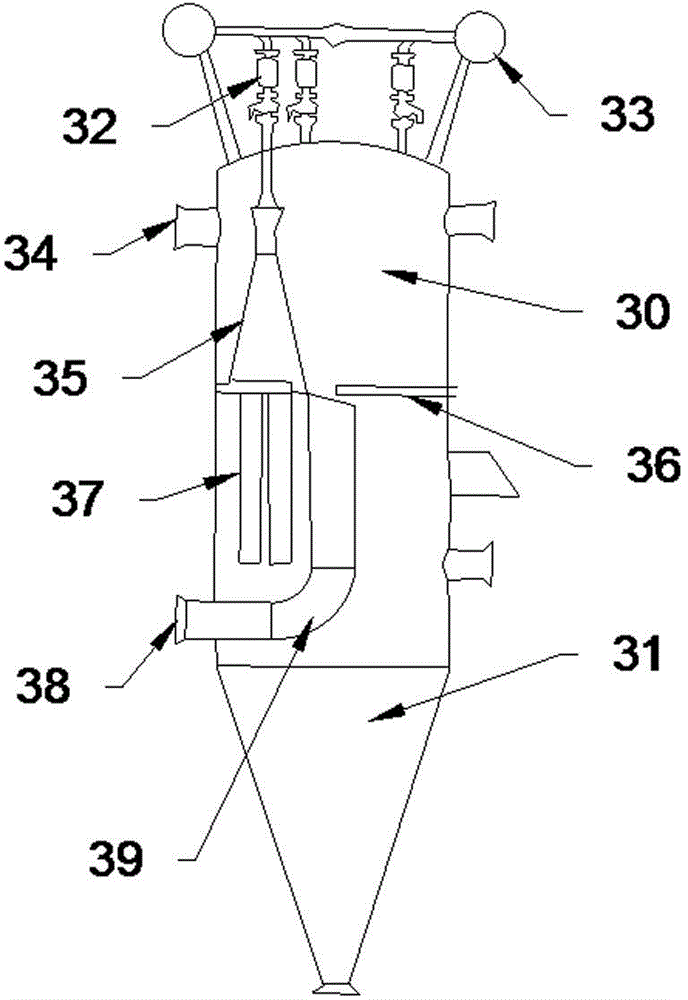

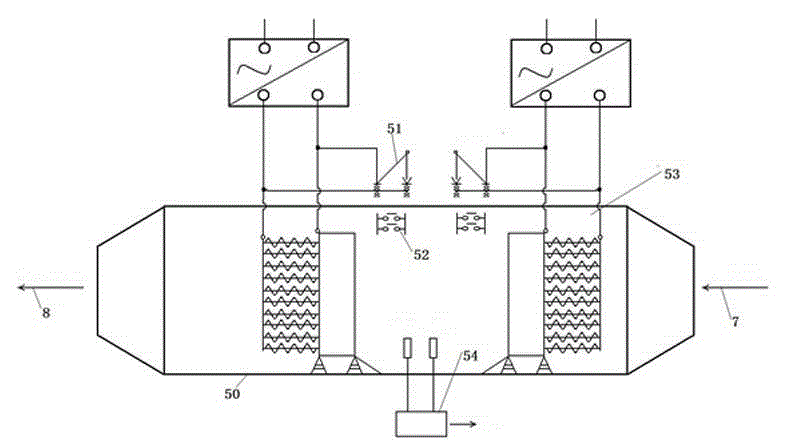

[0014] see Figure 1-3 , a flue gas treatment device for domestic waste incineration, including a rapid cooling device, a high temperature dust removal device 3, a plasma device 5 and a chemical washing device 6, the rapid cooling device includes a first rapid cooling device 2 and a second rapid cooling device 4 , connected with the first rapid cooling device 2, the high temperature dust removal device 3, the second rapid cooling device 4, the plasma device 5 and the chemical washing device 6 successively from left to right, and the high temperature dust removal device 3 includes a blowback gas storage tank 33, Pulse valve 32, distribution pipe 39, clean gas chamber 30 and rough gas chamber 31, back-flush gas storage tank 33 is located at the upper end of clean gas chamber 30, clean gas outlet 34 is arranged on both sides of clean gas chamber 30, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com