Wire tube evaporator assembly and refrigerator in a tank

A wire-tube evaporator and box liner technology, which is applied to evaporators/condensers, refrigeration components, coolers, etc., can solve the problems of high temperature of box liner, blackening of smoke, increase of scrap rate of box liner, and increase of assembly cost. , to reduce the scrap rate, facilitate the operation of on-site workers, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

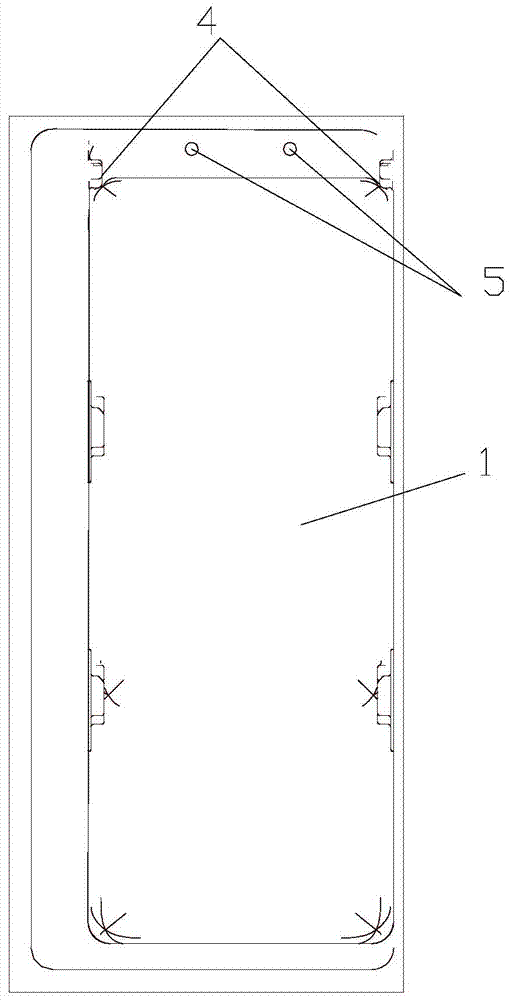

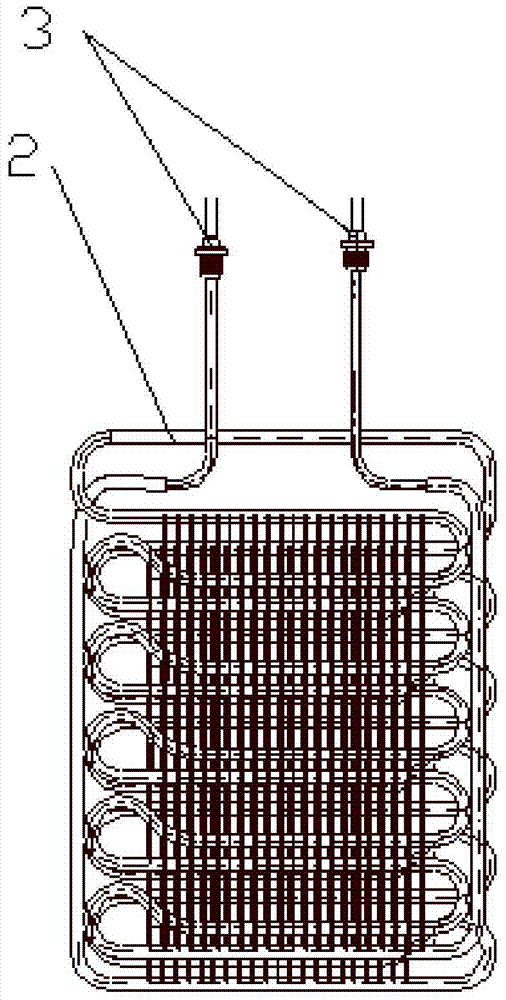

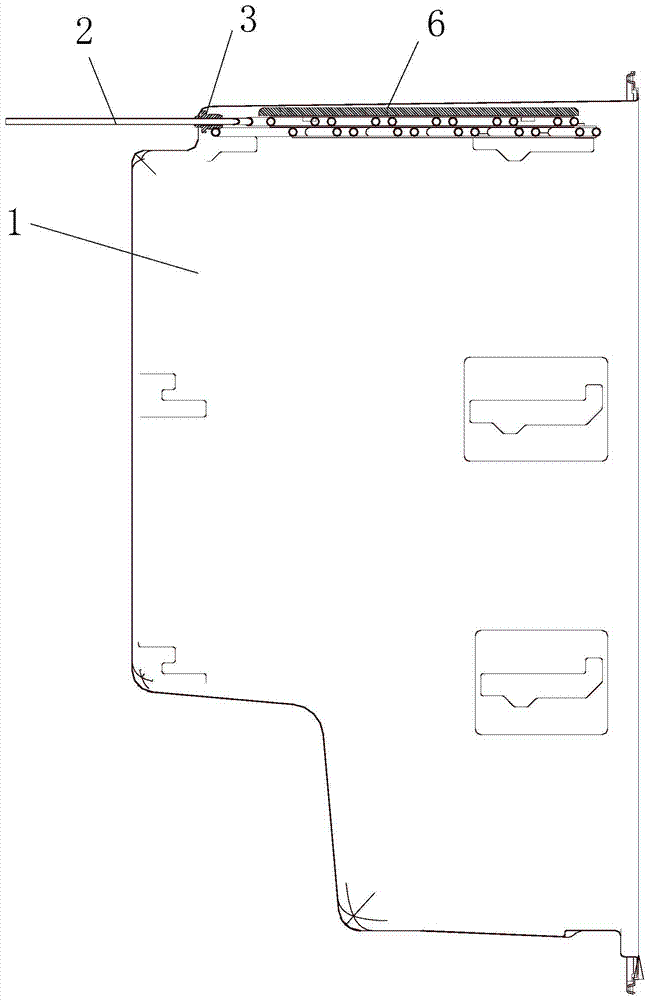

[0031] like Figure 1 to Figure 3 As shown, a wire tube evaporator assembly in a tank includes a tank 1 and a wire tube evaporator 2 inside the tank 1, and the inlet and outlet of the wire tube evaporator 2 are located in the wire tube On the same side of the evaporator 2, the tank 1 is provided with circular holes 5 corresponding to the inlet and outlet of the silk tube evaporator 2 respectively, and the inlet and outlet of the silk tube evaporator 2 respectively pass through the The circular hole 5 protrudes from the outside of the tank 1 .

[0032] Preferably: the inlet and outlet of the silk tube evaporator 2 are located on the same level. It is convenient for production and installation, simplifies the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com