Motor train unit wheel hub diameter detection device and using method thereof

A technology for detection devices and EMUs, applied to electromagnetic measurement devices, electric/magnetic diameter measurement, etc., can solve problems such as inability to provide measurement results, achieve the effects of improving detection efficiency and detection accuracy, low cost, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

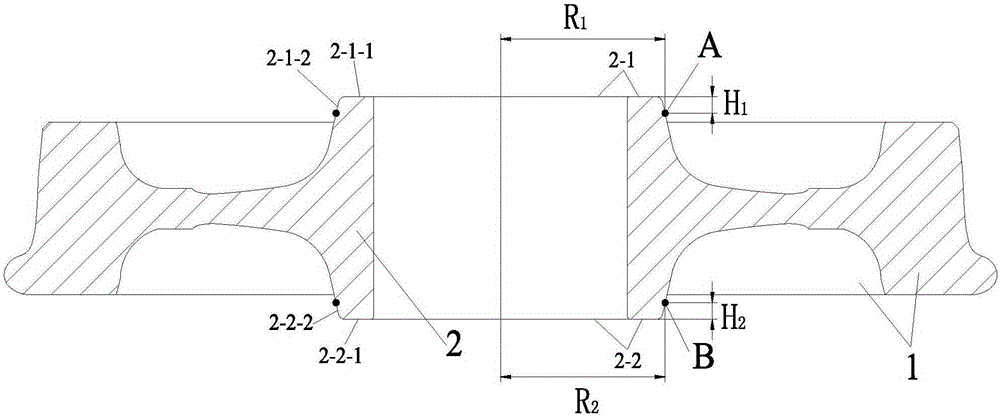

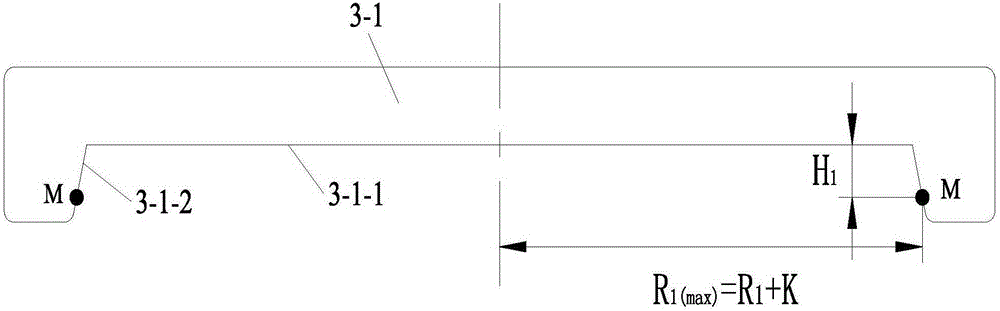

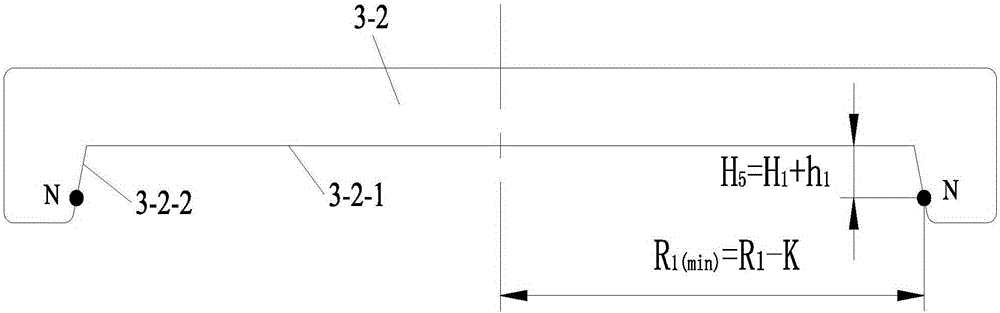

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] like Figure 8 to Figure 12 As shown, the EMU wheel hub diameter detecting device of the present invention comprises a vernier ruler slideway 4, a vernier measuring end seat 5, a fixed measuring end seat 6, a first end face height positioning seat 7, a second end face height positioning seat 10, a A ball stud 8, a second ball stud 9 and four height calibration blocks 11, the fixed measuring end seat 6 is fixedly connected with the left end of the vernier ruler slideway 4, and the vernier measuring end seat 5 is set on the vernier ruler sliding outside of road 4 and can slide along it. Two groups of small screw holes 4-1 are respectively provided with two groups of small screw holes 4-1 on both sides of the middle section of the vernier ruler slideway 4, and each group of small screw holes includes two small screw holes, and the center line of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com