Simple measuring method for content of micro-fine-particle-level particles

A technology of particle content and measurement method, which is applied in the direction of weighing by removing certain components, can solve the problems of not having a laser particle size analyzer, not being able to know the particle size distribution of tailings in time, and long measurement periods, etc., to achieve avoid inconvenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

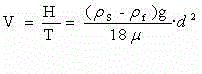

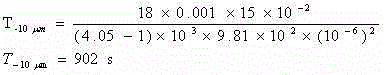

[0017] As shown in the figure, a simple method for measuring the content of fine particles according to the present invention includes the following steps:

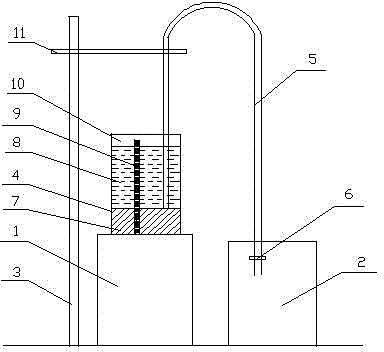

[0018] (1) Use laboratory beakers, test tube racks, soft rubber tubes, and clamps to make a simple liquid separation device. The liquid separation device includes a workbench 1, with a support rod 3 on one side of the workbench 1, and an overflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com