Intelligent routing inspection system and method of factory running device

A technology for operating equipment and intelligent inspection, applied in the direction of cooperative devices, instruments, computer components, etc., can solve the problems of uncontrollable equipment operation status, untimely maintenance and processing, and inspection data distortion, etc., to reduce faults and The incidence of accidents, the realization of intelligent inspection, and the effect of improving the level of operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

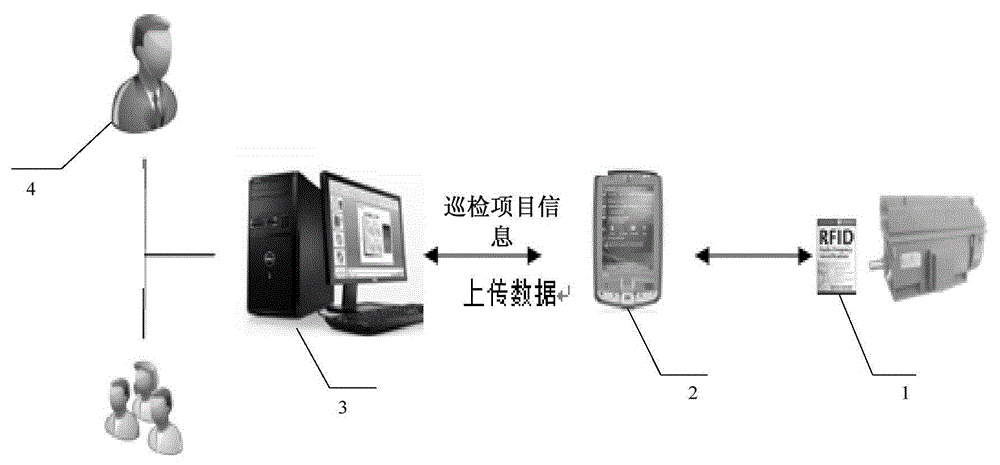

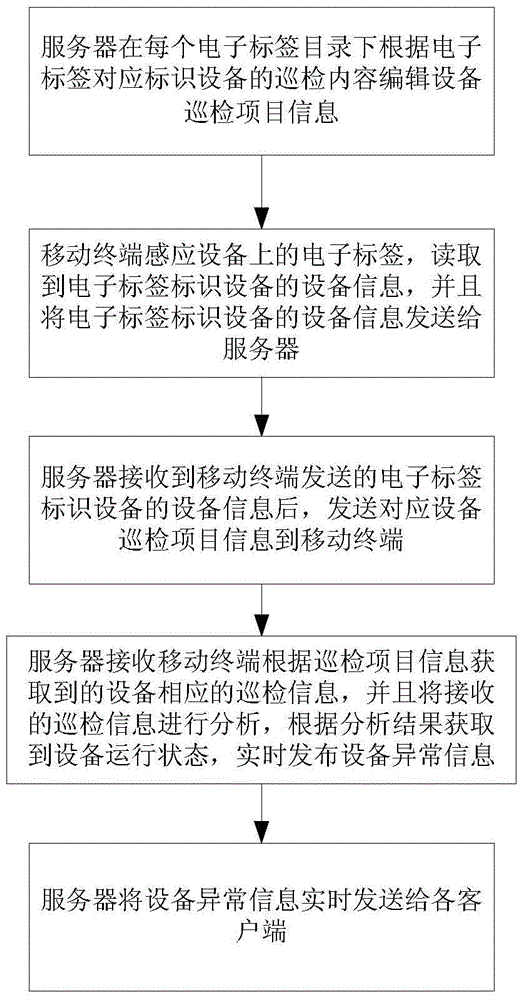

[0043] This embodiment discloses an intelligent inspection system for factory operation equipment, such as figure 1 shown, including:

[0044] The electronic label 1 is configured to be set on the device and store corresponding device information as a device identifier. Wherein the electronic tag in this embodiment is an RFID electronic tag.

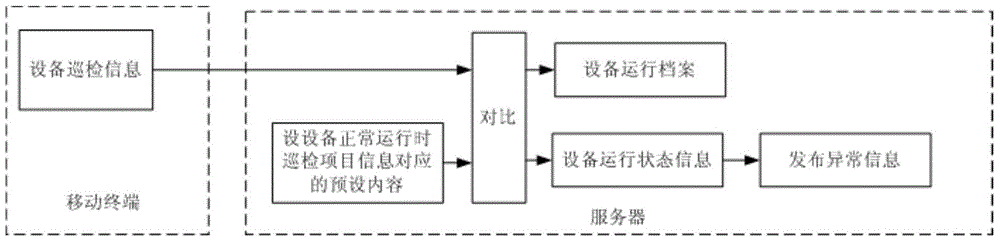

[0045] The mobile terminal 2 is used to sense the electronic tags on each device, to read the device information of the device identified by the electronic tag, to send the read device information to the server, to receive and display the corresponding device inspection sent by the server Project information: used to obtain the corresponding inspection information of the device according to the inspection project information and send it to the server. The mobile terminal in this embodiment may be a handheld device.

[0046]The server 3 is used to edit the equipment inspection item information according to the needs of the electronic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com