Three-dimensional dynamic anti-fake product with multiple anti-fake patterns

A pattern and dynamic technology, applied in the field of three-dimensional dynamic anti-counterfeiting products, can solve the problems of single anti-counterfeiting pattern, easy to be counterfeited, and simple structure of reflective sheet, so as to improve anti-counterfeiting strength, not easy to counterfeit or imitate, and easy to identify.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

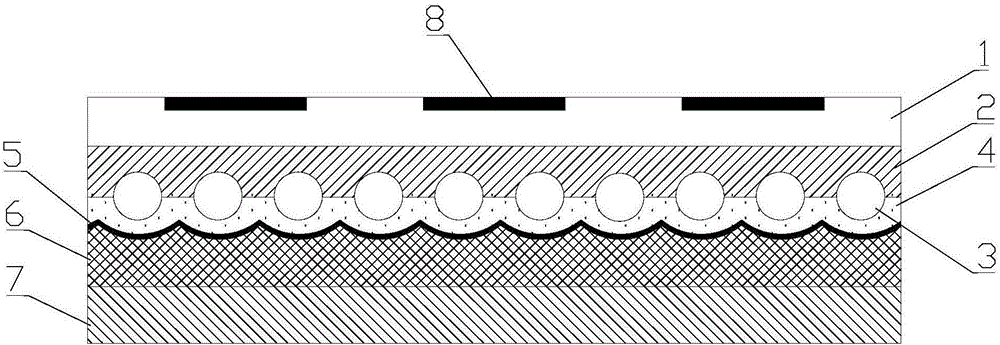

[0027] Such as figure 1 and figure 2 As shown, a three-dimensional dynamic anti-counterfeiting product with a plurality of anti-counterfeiting patterns includes a surface protection layer 1, a support layer 2, glass beads 3, a focus forming layer 4, a reflective layer 5, an adhesive layer 6, a protective paper 7 and a printing Layer 8.

[0028] The surface protection layer 1 is a light-transmitting smooth film-like resin layer or a frosted film-like resin layer, consisting of 100 parts by weight of acrylic resin solution, 16 parts by weight of methylated melamine resin solution, and 6 parts by weight of cellulose derivatives. , 1.5 parts by weight of UV absorber, 0.05 parts by weight of leveling agent, 0.12 parts by weight of catalyst and 16.7 parts by weight of methyl isobutyl ketone / toluene solution in a mixing ratio of 8 / 2 are coated on the engineering substrate film formed after drying.

[0029] The surface protection layer 1 is pasted on the support layer 2, and the s...

Embodiment 2

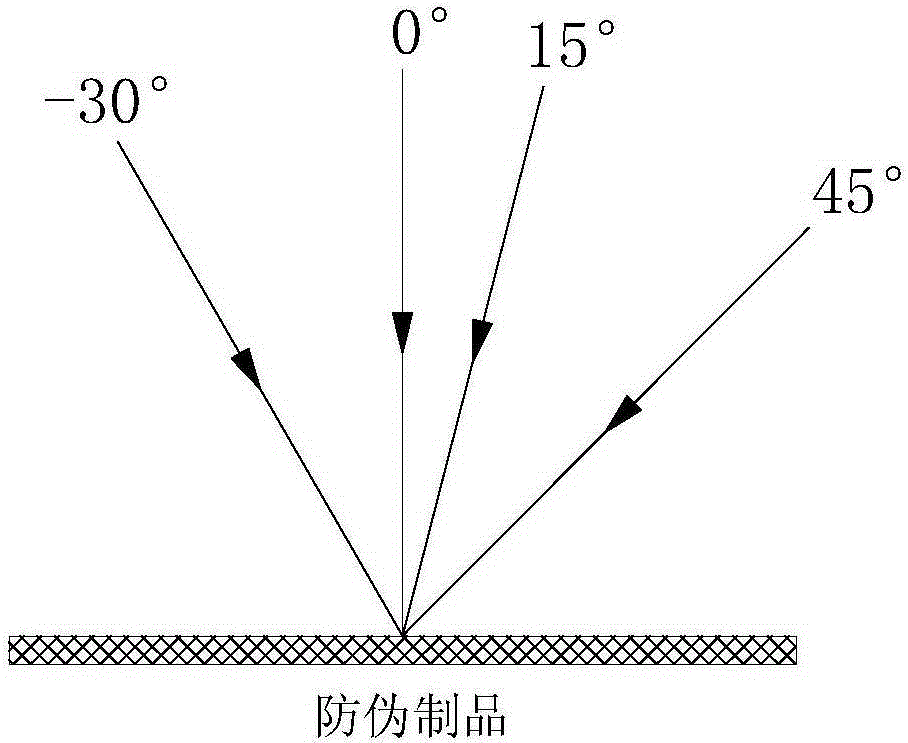

[0041] In this embodiment, the basic structure of the anti-counterfeit product is the same as that in Embodiment 1, and will not be repeated here, except that the reflection angle produced by laser irradiation is different.

[0042] There are 4 anti-counterfeiting patterns irradiated by laser light on the glass beads 3, the focus forming layer 4, the reflective layer 5 or on one of them, each anti-counterfeiting pattern has an independent reflection angle, and every two adjacent reflection angles are separated by 5 ° above. Such as image 3 As shown, the reflection angles of the four anti-counterfeiting patterns are respectively set to -30°, 0°, +15°, +45°.

Embodiment 3

[0044] In this embodiment, the basic structure of the anti-counterfeit product is the same as that in Embodiment 1, and will not be repeated here, except that the reflection angle produced by laser irradiation is different.

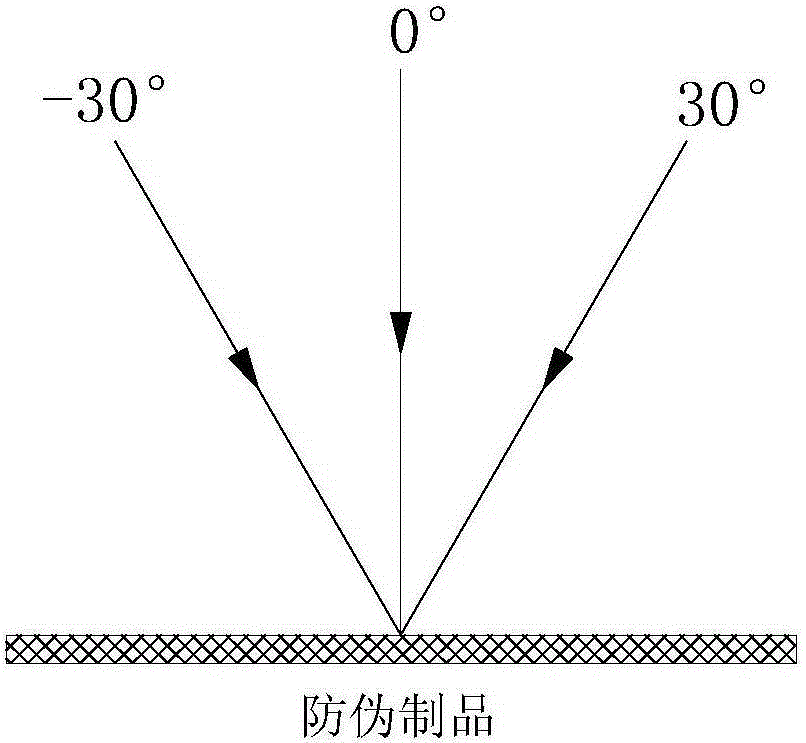

[0045] There are 5 anti-counterfeiting patterns irradiated by laser on the glass beads 3, the focus forming layer 4, the reflective layer 5 or one of them, each anti-counterfeiting pattern has an independent reflection angle, and every two adjacent reflection angles are separated by 5 ° above. Such as Figure 4As shown, the reflection angles of the five anti-counterfeiting patterns are respectively set to -60°, -30°, 0°, +30°, +60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com