an electric push rod

An electric push rod and push rod technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high cost and easy damage of push rods, and achieve the effect of good positioning effect, avoiding loss and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

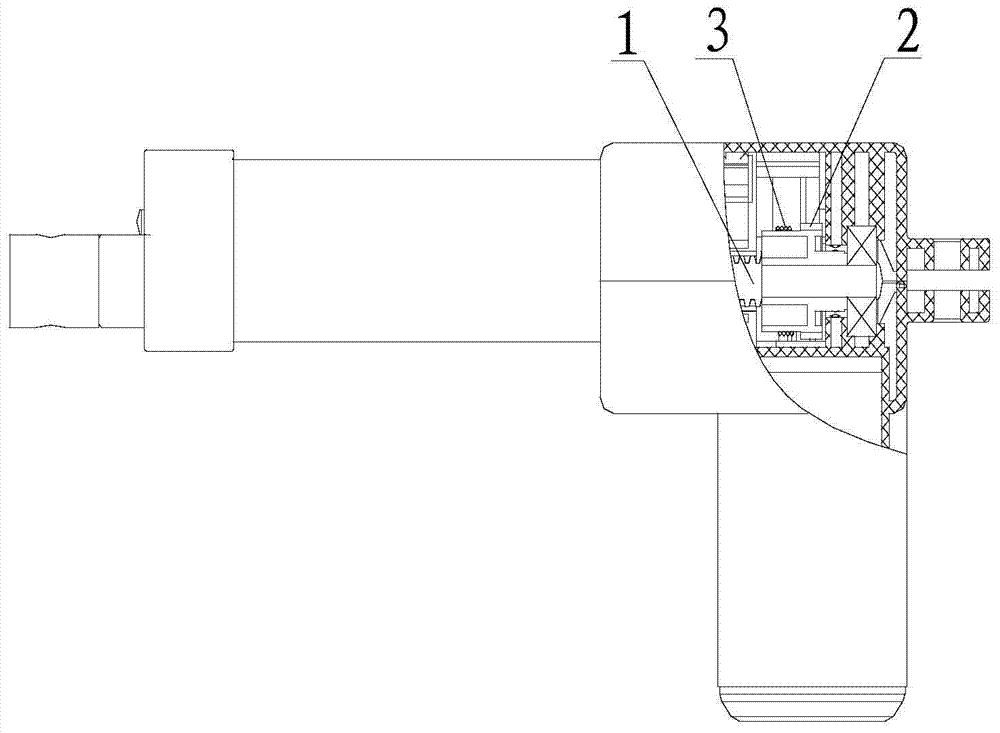

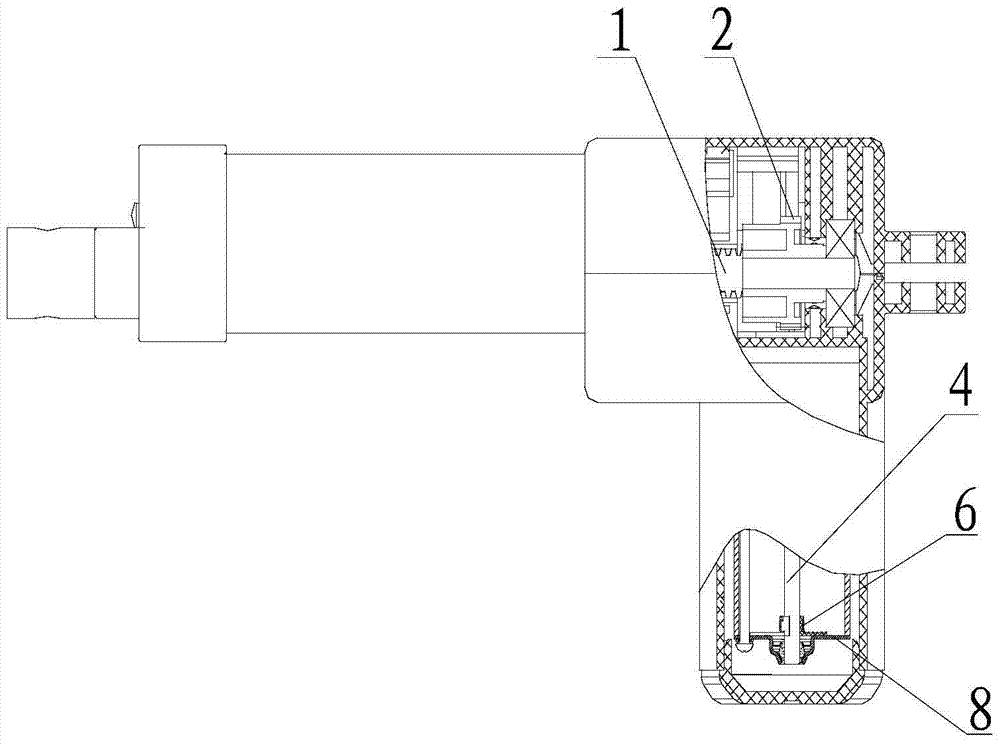

[0027] attached figure 2 It shows a structure diagram in which a damping device acting on the output shaft 4 is provided at the rear end of the output shaft 4 on the motor, and is arranged between the motor coil and the rear support bearing, which embodies the first implementation of the present invention Way.

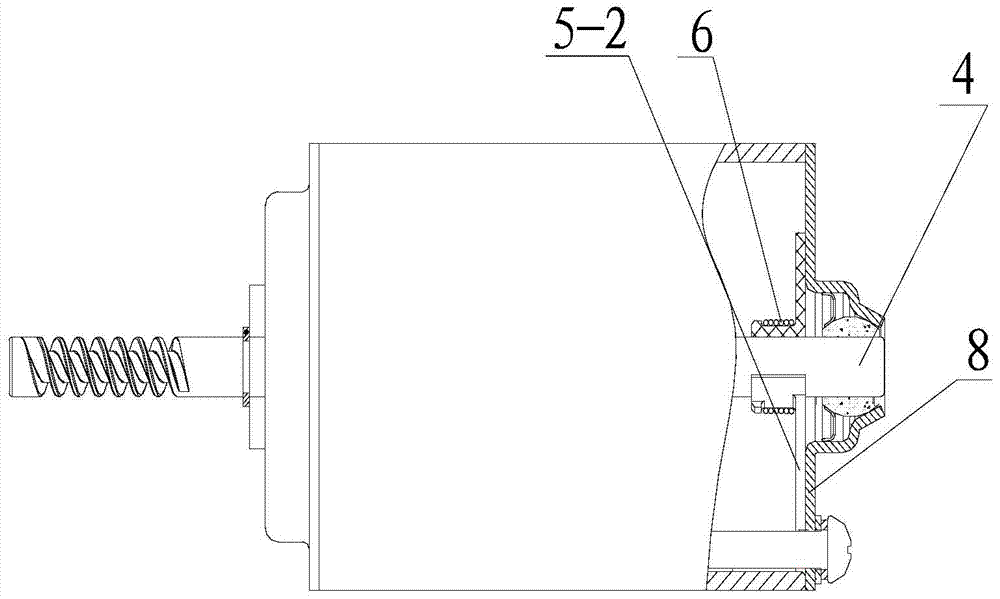

[0028] For the second mode of the structure in which the damping device is installed on the protruding part of the output shaft 4 from the rear end cover 8 of the motor, see the attached Figure 6 , the third way to install it on the front end of the output shaft 4 is shown in the attached Figure 7 , The latter two ways are mainly different in position and an outer cover is added as required, and the stopper 7 in the damping device is arranged on the non-rotating parts of the motor according to the situation.

[0029] attached image 3 combined with Figure 4 And attached Figure 5 It shows that the structure of the damping device includes two friction shoes 5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com