Roller for a machine for producing, further processing and/or finishing a fibrous material web

A fiber web and roller technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

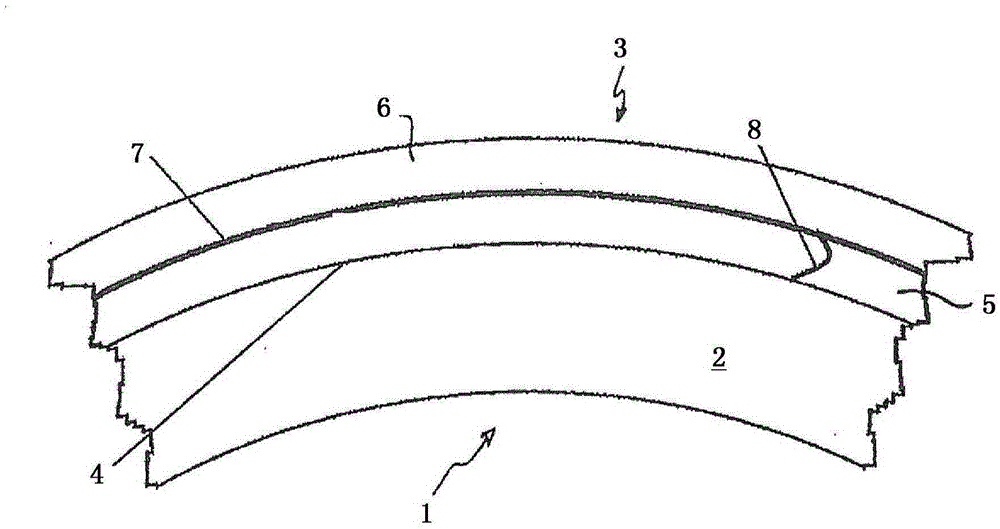

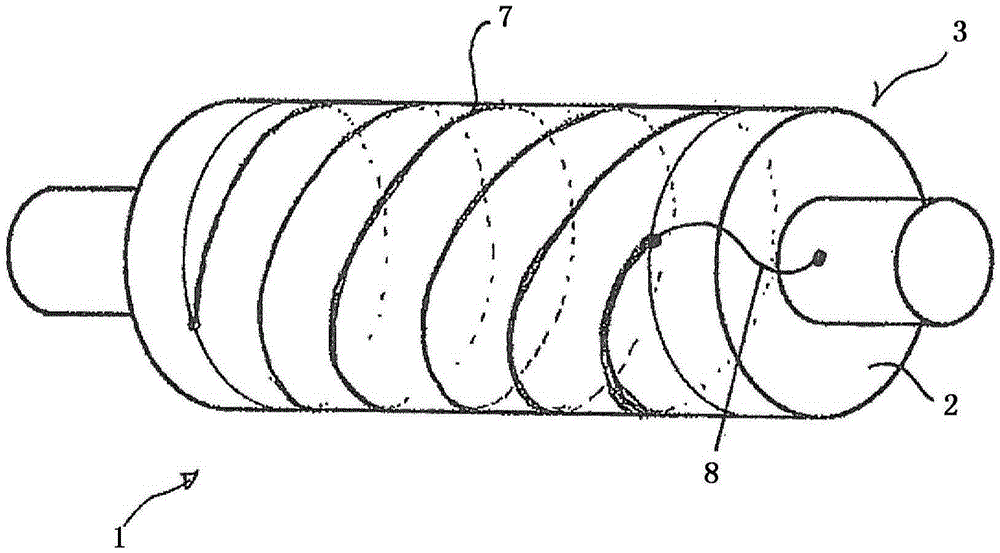

[0035] Possible configurations of calender roll sleeves for electrical conductivity:

[0036] Here, the electrical conductivity is reduced by the alternative reinforcement carrier in the active layer 6 , the intermediate layer 5 electrically connected to the roller core 2 and the known adhesion promoter layer 4 .

[0037] - Adhesion promoter layer 4 implemented in a known manner

[0038] - an intermediate layer 5 implemented in a known manner

[0039] - one or more copper wires wound helically in the circumferential direction

[0040] - Effect layer 6:

[0041] Fill epoxy with inorganic fillers (~44%)

[0042] Aramid non-woven fabric with 97% hydroentangled para-aramid, 3% silver filaments, approximately 60g / m 2 flat ground

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com