A four-knife round pot type pepper chopping machine

A pepper chopping machine and technology for chopping peppers, applied in grain processing, food forming, food science, etc., can solve the problems of complex and frequent maintenance, short service life of the whole machine, fast loss of parts, etc., to improve transmission efficiency and stable operation performance, ensure working strength and service life, and reduce the probability of damage and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

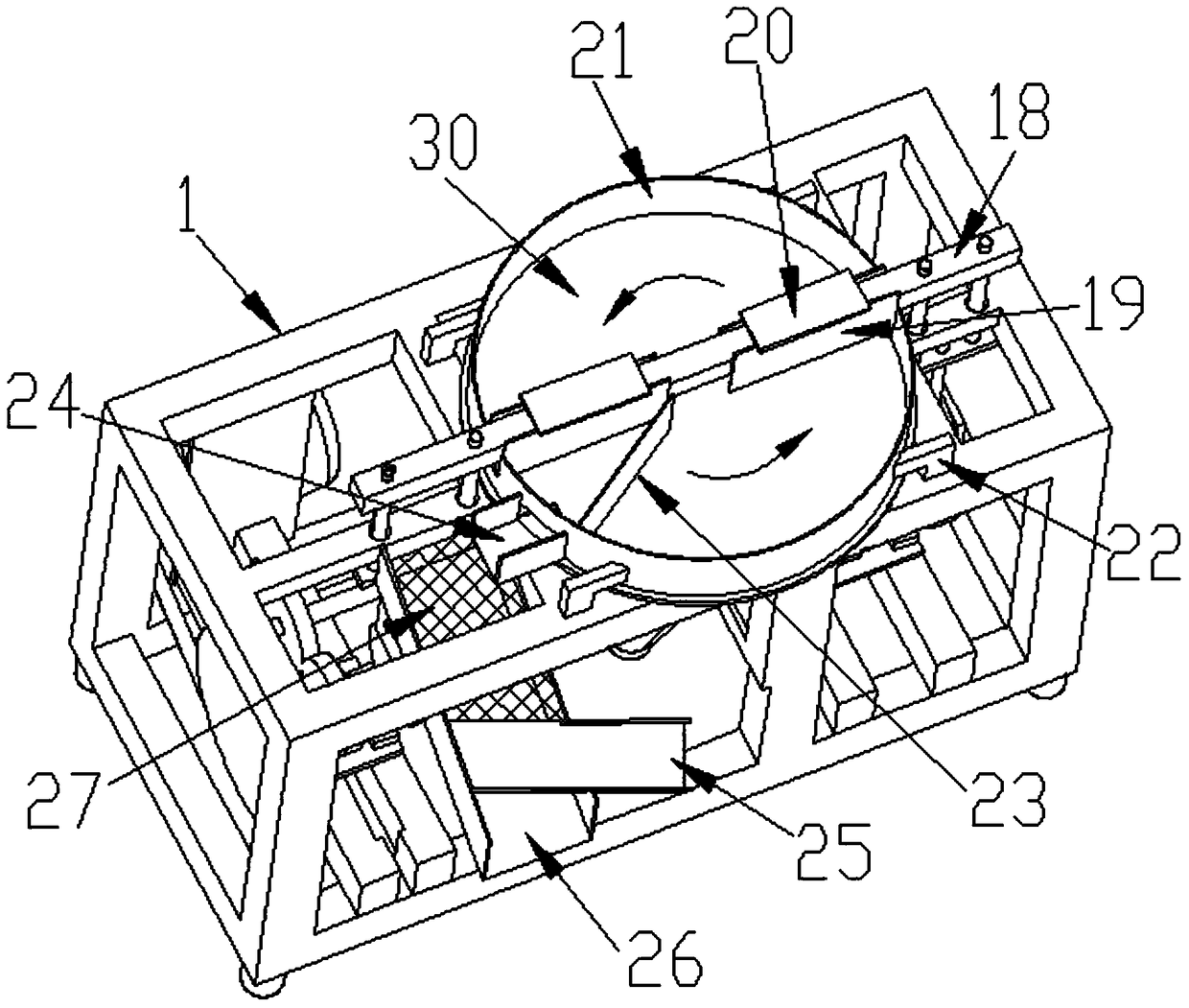

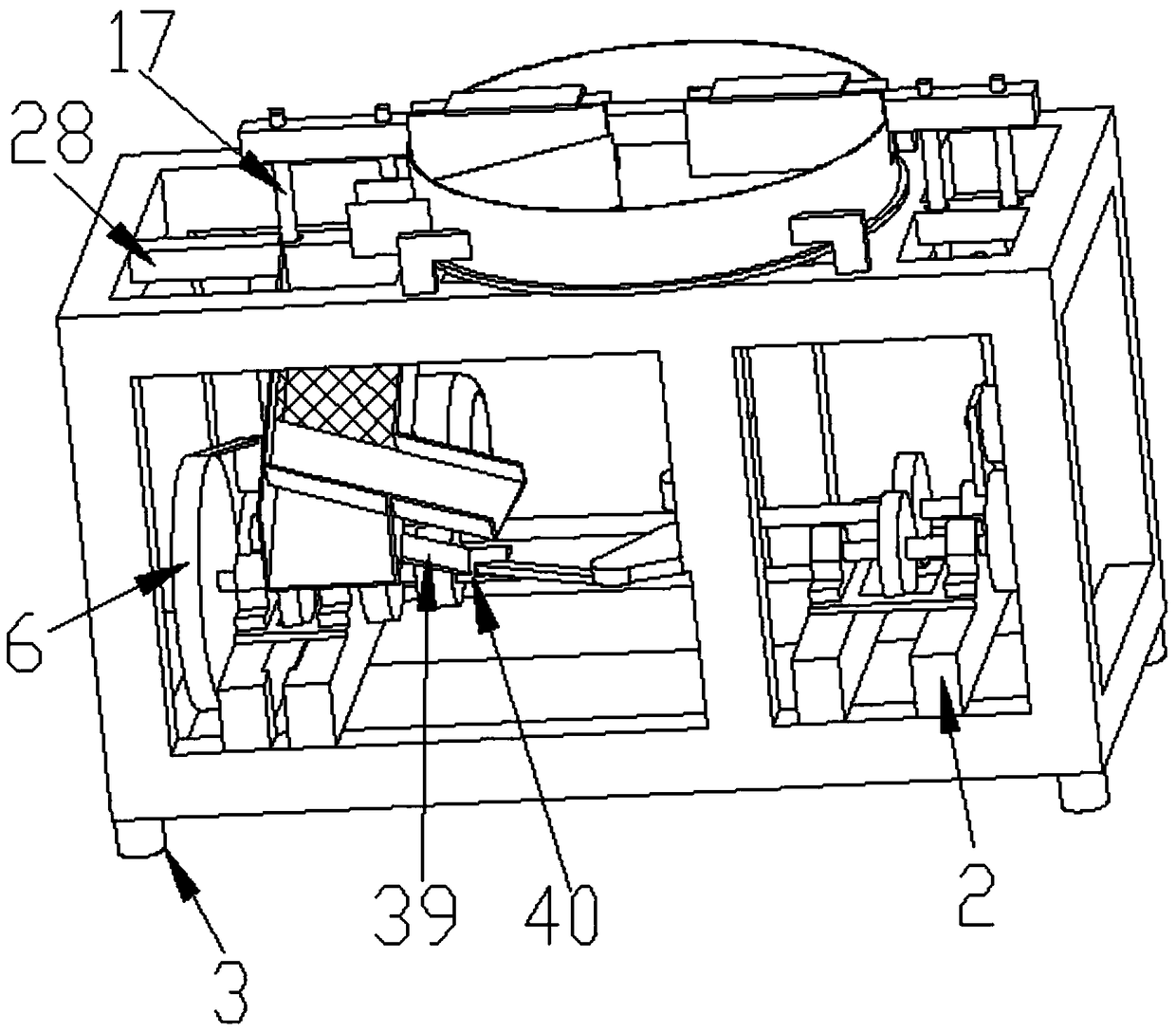

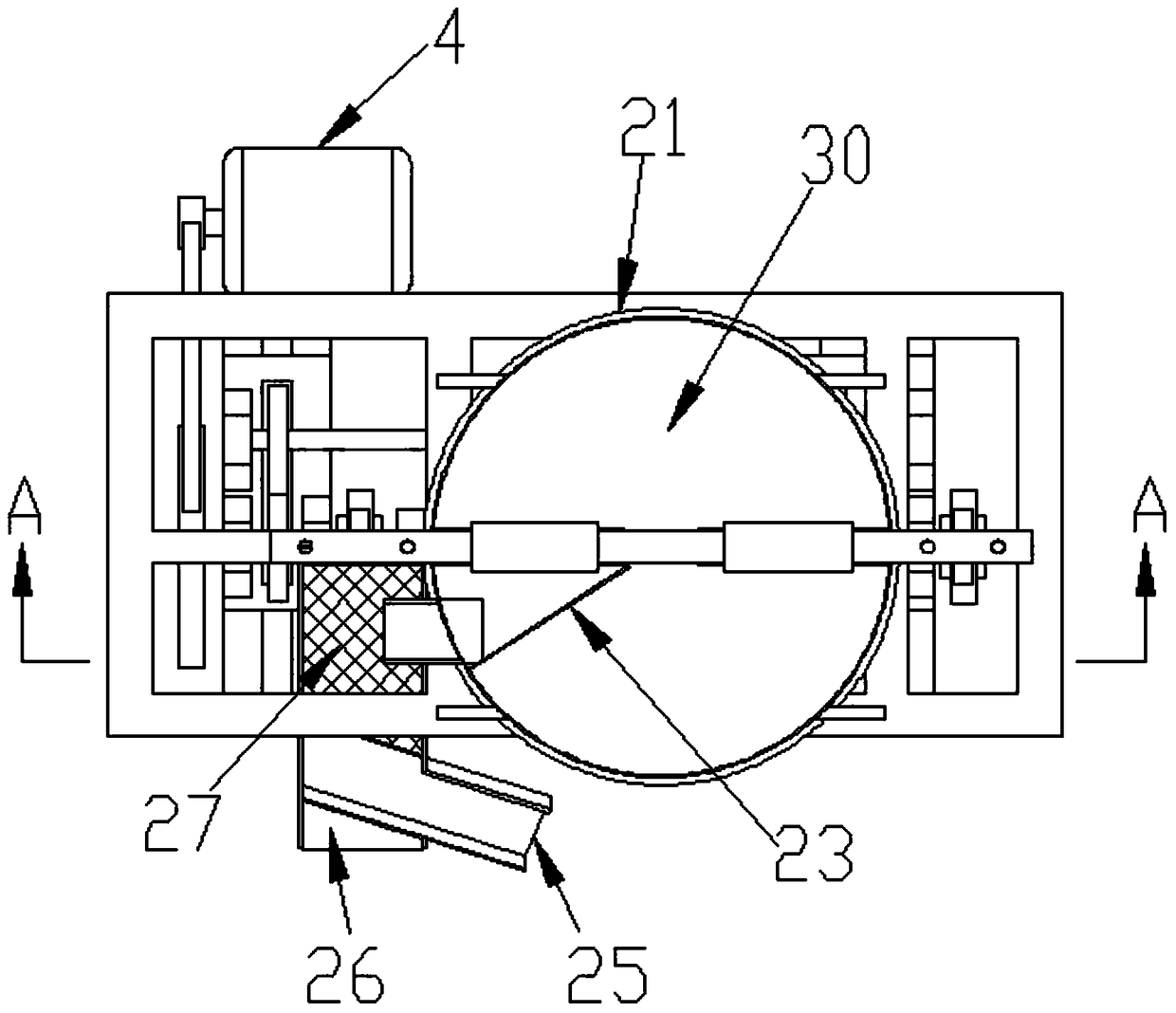

[0035] Such as Figure 1-7Shown, the structural connection relation of the present invention is: a kind of four-knife round basin type pepper chopping machine, it comprises general support 1 and the pad foot 3 that is arranged on its lower end four feet, the transmission mechanism that is arranged on its inside, is arranged on its upper end The chili pepper mechanism, the chili pepper mechanism includes a rotating circular chopping board 30 and an annular fence 21 arranged around its upper end; the inner wall of the annular fence 21 is provided with a material retaining plate 23; the annular fence 21 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap