Device for curing and hanging tobacco for flue-cured tobacco and method of using the same

A technology for tobacco and flue-cured tobacco, which is applied in the fields of application, tobacco, and preparation of tobacco, can solve the problems of poor overall quality, and the base of tobacco leaves contains a lot of green, and achieves the effects of convenient smoking, wide selection and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

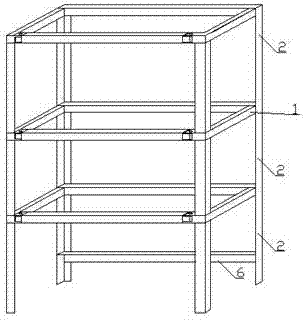

[0028] This application proposes a new way of loading flue-cured tobacco, which is based on a hanging rack. For the convenience of understanding, we now combine figure 1 A detailed description of the cigarette rack of the present application, figure 1 The tobacco hanging rack in the table is one of the ones put in the barn. When using it, the tobacco hanging racks full of tobacco leaves need to be arranged neatly and piled up in the barn. figure 1 It can be seen that the main body that realizes the fixing of tobacco leaves is a rectangular tobacco rack 1 with more than two layers. According to the height of the existing barn, three layers are preferred. The rectangular tobacco rack 1 is formed by connecting 1-1.5cm galvanized square pipes Rectangular metal frame, when making, one long side of the rectangular metal frame is a movable connection, and the movable long side can be realized by cooperation of a hinge and a latch.

[0029] In order to realize multi-layer stacking, m...

Embodiment 2

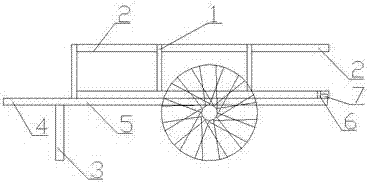

[0040] This application proposes a new way of loading flue-cured tobacco, which is based on a hanging rack. For the convenience of understanding, we now combine figure 1 with figure 2 A detailed description of the cigarette rack of the present application, figure 2The tobacco hanging rack in the table is one of the ones put in the barn. When using it, the tobacco hanging racks full of tobacco leaves need to be arranged neatly and piled up in the barn. figure 2 It can be seen that the main body that realizes the fixing of tobacco leaves is a rectangular tobacco rack 1 with more than two layers. According to the height of the existing barn, three layers are preferred. The rectangular tobacco rack 1 is a rectangular metal frame formed by connecting 1cm galvanized square pipes. , when making, one long side of the rectangular metal frame is a movable connection, and the movable long side can be realized by the cooperation of a hinge and a latch.

[0041] In order to realize mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com