Novel special reaction kettle for esterification reaction

A technology of esterification reaction and reaction kettle, which is applied in the field of a new type of special reaction kettle for esterification reaction, can solve the problems of difficult accurate control of the esterification reaction process, product scrapping, and difficulty in grasping, so as to improve the quality of finished products and save energy , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

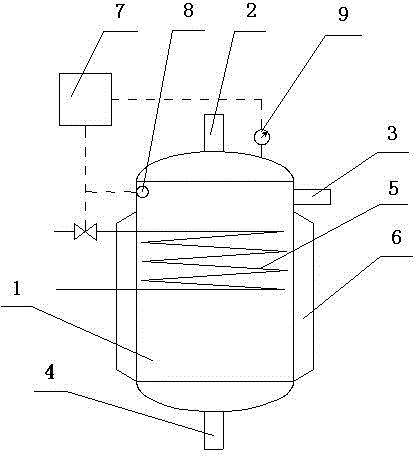

[0009] As an embodiment of the present invention, such as figure 1 As shown, a new type of special reactor for esterification reaction, including a reactor body 1, the upper end of the reactor body 1 is provided with a feed inlet 2, the lower end is provided with a discharge port 4, and the side wall of the reactor body 1 is provided with a gas outlet 3. It also includes a controller 7. A heat exchanger 5 and a temperature sensor 8 are arranged inside the reactor body 1. A vacuum pressure gauge 9 is arranged on the top of the reactor body 1. The vacuum pressure gauge 9, heat exchanger 5 and The temperature sensors 8 are electrically connected with the controller 7 respectively, and the inner wall surface of the reactor body 1 is provided with a ceramic layer, which improves the corrosion resistance of the present invention and prolongs the service life of the equipment. The outer surface of the side wall of the reaction kettle body 1 is provided with a jacket 6, which has a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com