Special straightening machine for vehicle frame longitudinal beam flanges

A straightening machine and longitudinal beam technology, which is applied in the field of sheet metal weldment straightening, can solve the problems of low manual straightening efficiency, poor straightening effect and safety, etc., and achieve the effect of simple and effective structure, low processing difficulty and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

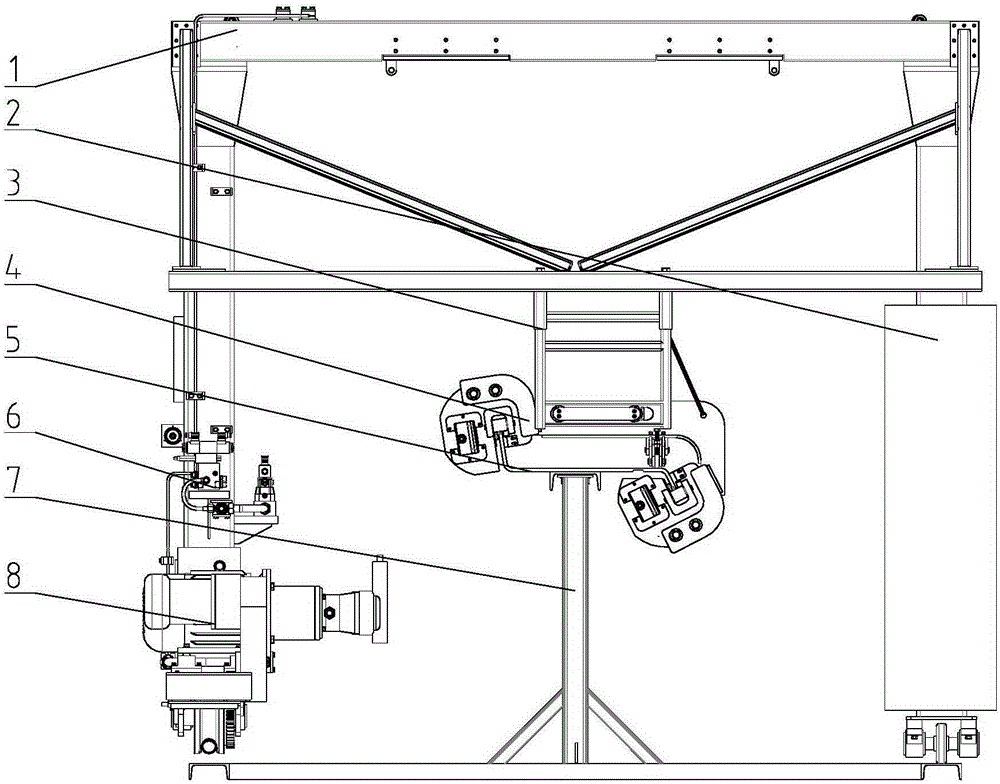

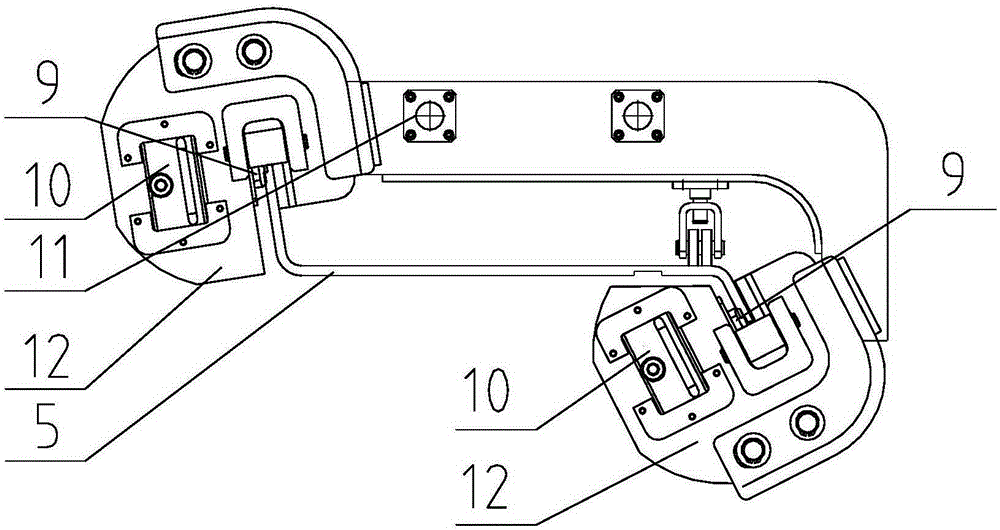

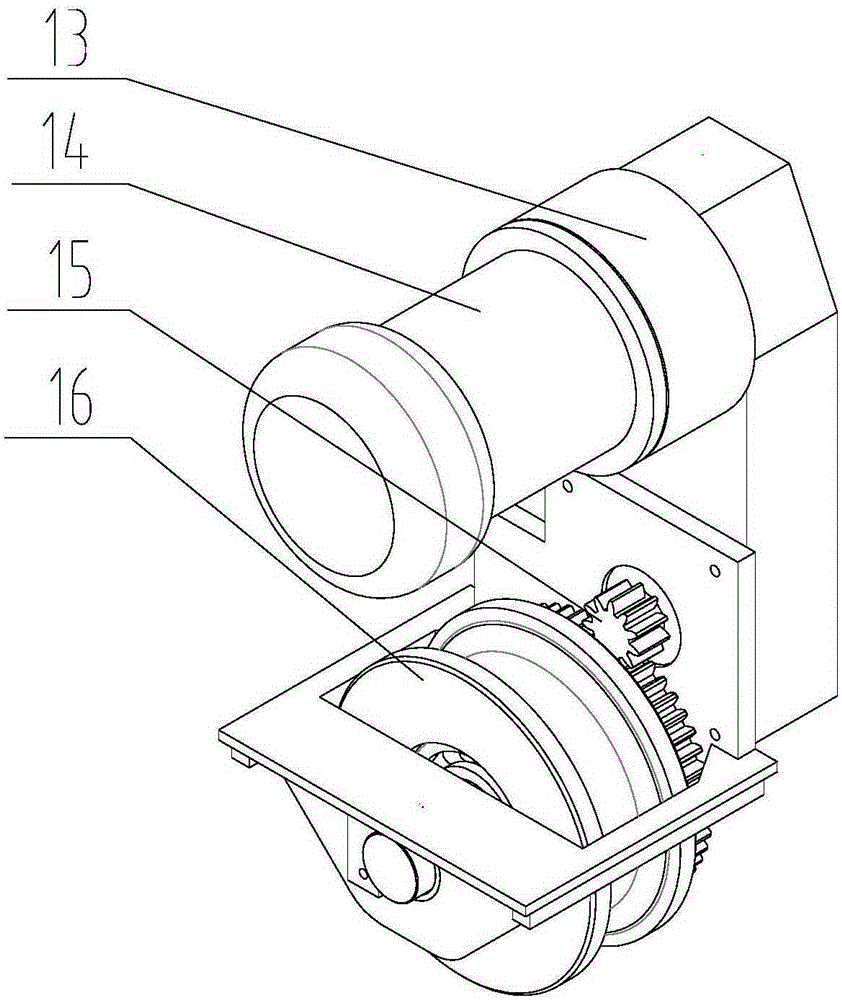

[0028] refer to figure 1 As shown, the special straightening machine for frame longitudinal beam flange in an embodiment provided by the present invention includes a mobile gantry 1, a straightening device 4, a hydraulic system 6 and an electric control system 2, and the mobile gantry 1 includes a gantry and a fixed rail, There is a pulley 16 at the bottom of the gantry, which moves linearly along the fixed track. The correction device 4 is suspended in the middle of the top of the mobile gantry 1. The correction device 4 includes correction pliers and a correction cylinder 10. The correction cylinder 10 provides power for the correction pliers to squeeze the workpiece 5 , so that the correcting pliers can apply pressure to correct the workpiece 5, simulating manual knocking on the flange of the workpiece 5, the hydraulic system 6 provides oil pressur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap