A fully automatic pipe bending machine

A pipe bending machine, fully automatic technology, applied in the direction of metal processing equipment, feeding device, positioning device, etc., can solve the problems that affect the product qualification rate, low centering efficiency, high labor cost, etc., achieve simple structure, small labor force, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

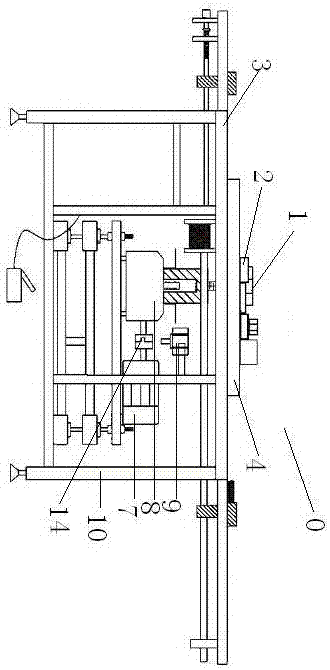

[0033] A fully automatic pipe bending machine, characterized in that, the fully automatic pipe bending machine 0 includes a pipe bending device 1, a clamping device 2 and an automatic centering device 3;

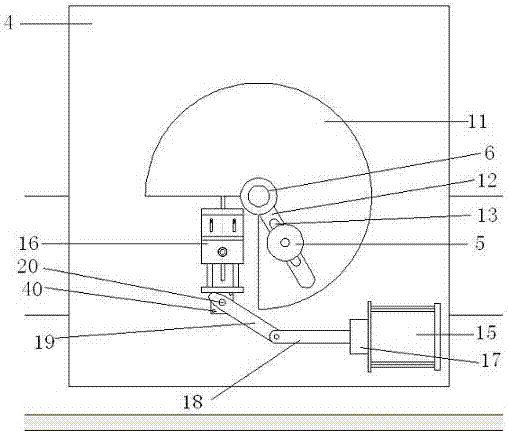

[0034] The pipe bending device 1 includes a panel 4, a movable mold 5, a fixed mold 6, a motor 7, a speed reducer 8 and a brake cylinder 9, the panel 4 is horizontally arranged by a support 10, the panel 4 is square, and there are 3 holes on it. / 4 circle movable mold movement port 11, the fixed mold 6 is fixedly arranged at the center of the 3 / 4 circle shown by the panel 4, and the reducer 8 is arranged at the center of the 3 / 4 circle shown by the panel 4 At the lower end, the output end of the speed reducer 8 is provided with a swing arm 12, the swing arm 12 is elongated, one end of which is fixedly connected to the output end of the speed reducer 8, and the swing arm 12 is provided with a movable mold adjustment port 13. The movable mold 5 is detachably connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com