Feed device pincers and feed device comprising said pincers

A technology of feeding device and raw material, which is applied to the feeding device of the main shaft and the clamp field of the feeding device, can solve the problem that the pneumatic jack is not easy to maintain, and achieve the effect of compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

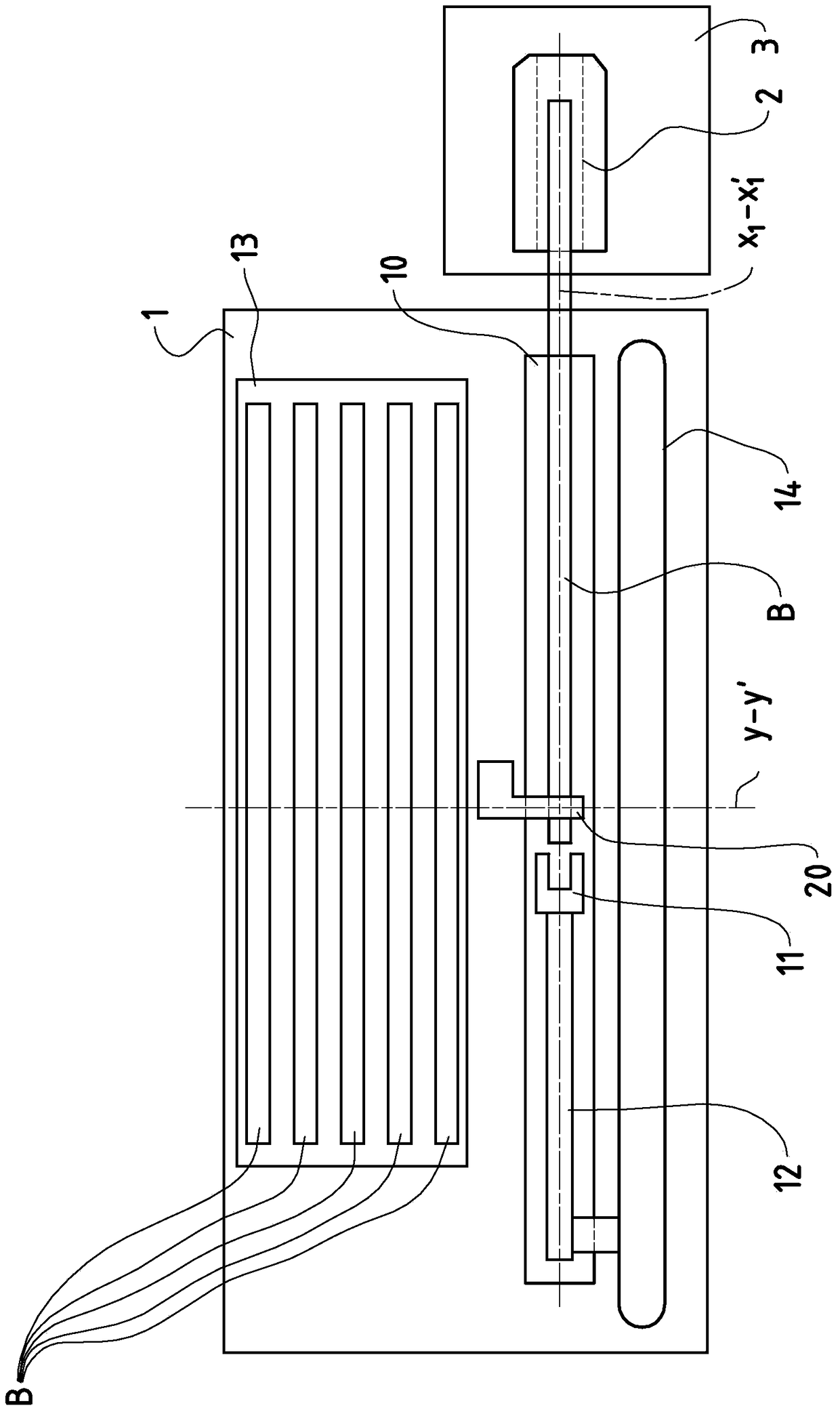

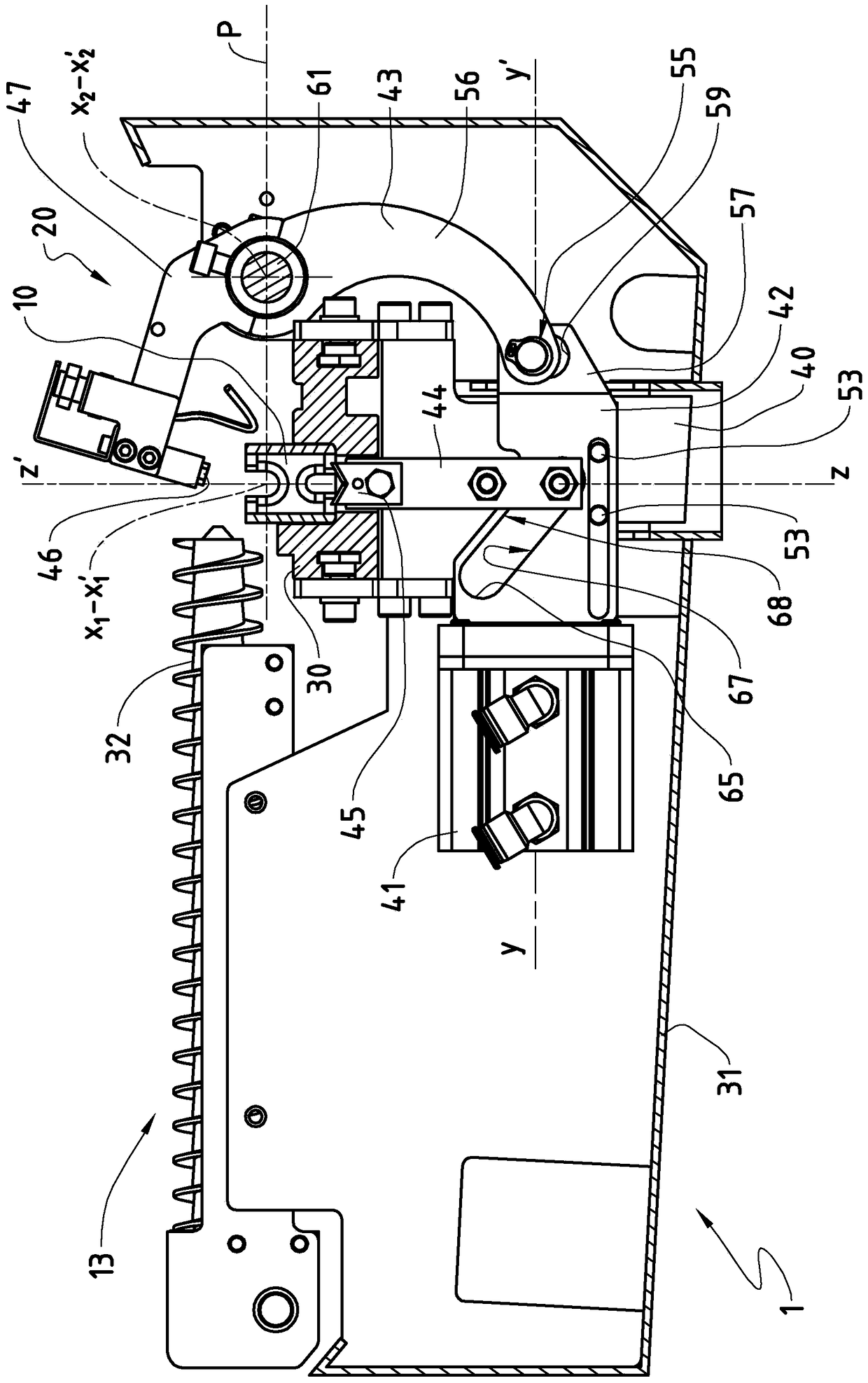

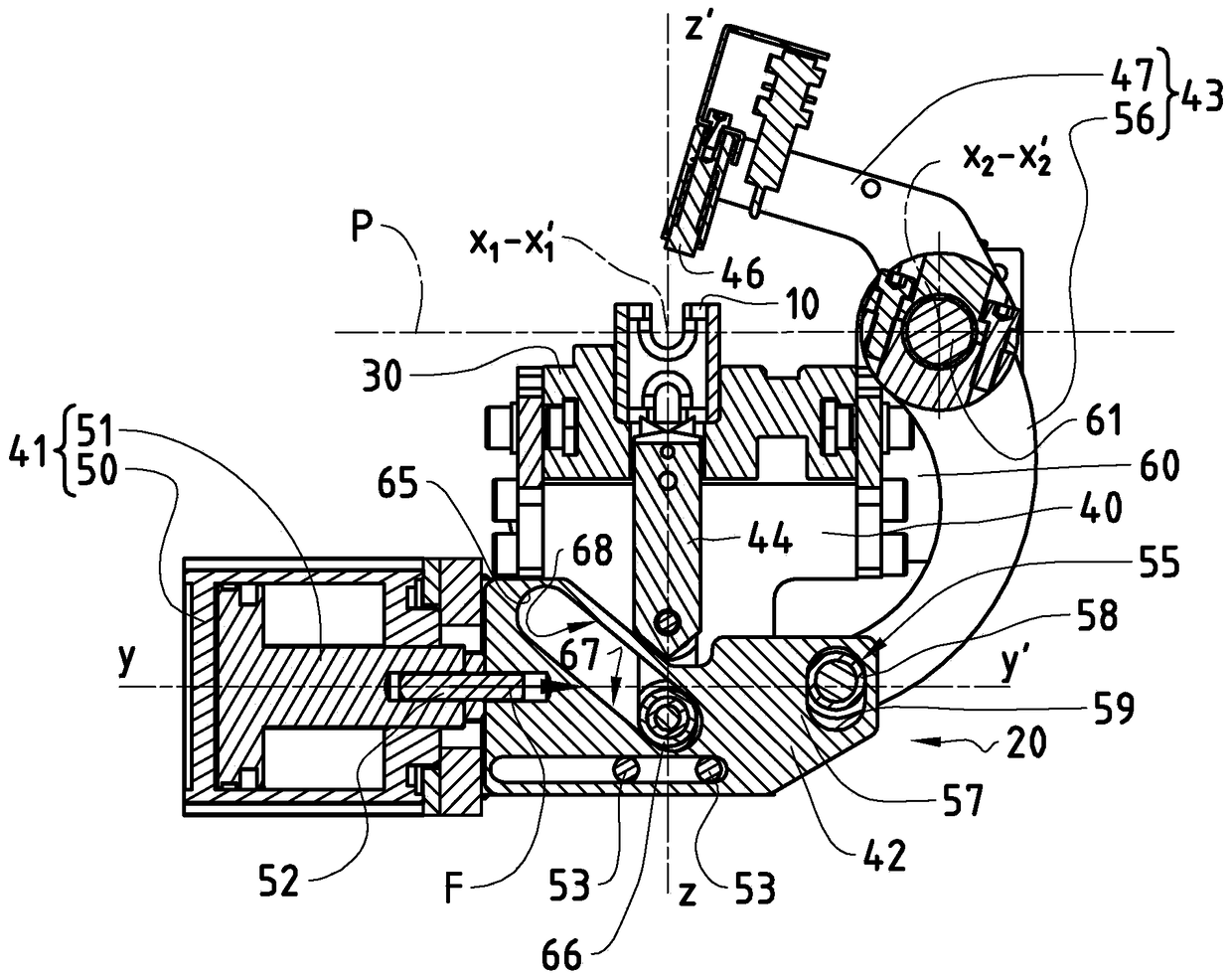

[0038] figure 1 A feeding device 1 according to an embodiment of the present invention is provided for sequentially loading raw rods B one by one onto a rotary drive spindle 2 of a processing unit 3 known per se. Said spindle 2 turns the stock bar B during processing, while a part of this stock bar is still supported by the feeder 1 . Components or other elements are produced by machining the front end of the raw material bar B. When the assembly or element is finished, the assembly or element will be separated from the remainder of the stock bar B. Thus, the front end of the raw material bar B is loaded between two subsequent processing devices.

[0039] The feeding device 1 comprises an axial guide channel 10 for axially guiding a raw material bar B, which is pushed into the processing unit 3 by a non-powered tongs 11 in front of an elongated pusher 12 . A drive device 14 is provided for driving the pusher 12 back and forth. The side supply box 13 stores the straight raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com