Welding fixture for eight-axis bogie frame of electric locomotive

A technology for welding fixtures and electric locomotives, used in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve problems such as low work efficiency, inaccurate relative positions, and affect welding quality, to ensure continuity and consistency. The effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

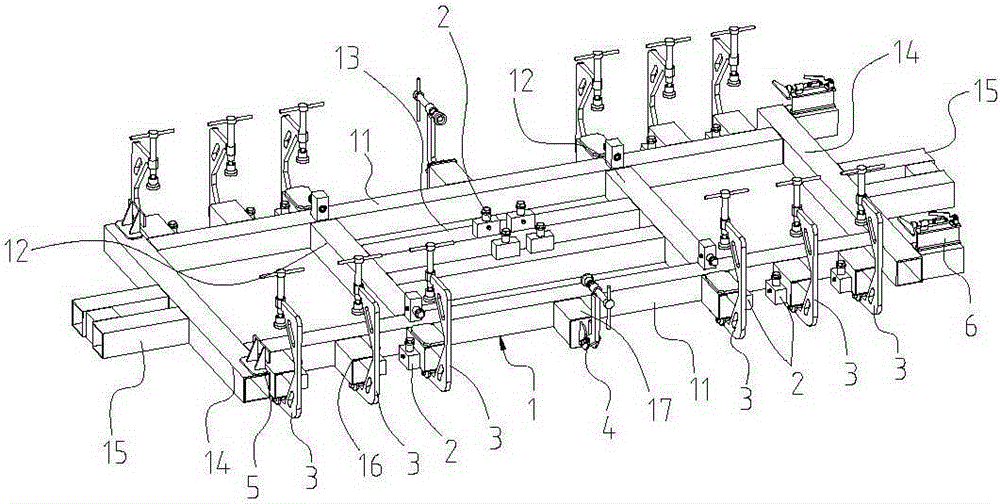

[0025] Such as figure 1 As shown, a welding fixture for an eight-axle bogie frame of an electric locomotive includes a support frame 1, and the support frame 1 includes two side beams 11 arranged in parallel, and a crossbeam 12 arranged in parallel between the two side beams 11 1. The end beams 14 respectively arranged at both ends of the side beams 11 and the connection seat 15 arranged in the middle of the end beams 14 to connect with the rotating equipment, and two parallel connecting beams 13 are arranged between the two cross beams 12 . The side beams 11, cross beams 12, end beams 14, and connecting beams 13 are all square steel pipes, and the joints of the side beams 11, cross beams 12, end beams 14, and connecting beams 13 are connected by welding, and the overall weight of the support frame 1 is relatively light. However, the structure is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com