Multi-shaft drilling and milling power head device with adjustable center distance

A technology of multi-axis drilling and center distance, applied in the direction of driving devices, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of low production efficiency, many processes, and poor precision, so as to improve processing efficiency and reduce transshipment inventory , easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

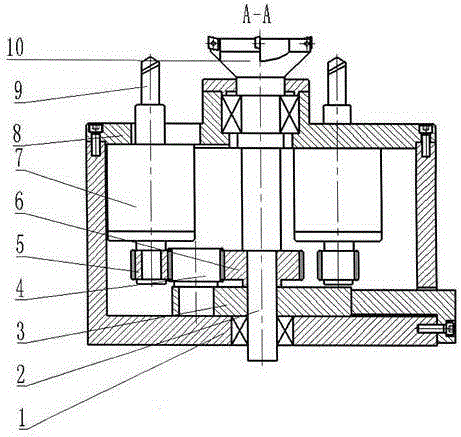

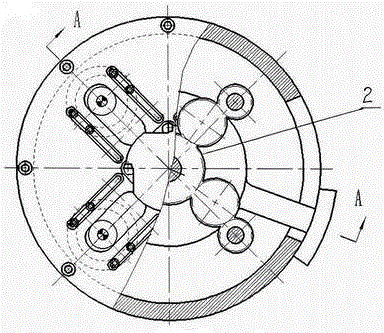

[0008] This technical solution integrates the processing of the bottom surface, the positioning boss and the mounting hole into one device. The mounting surface and the positioning boss are first milled through this device, and the mounting hole can be directly drilled; the center distance of the rotating shaft of the device is stepless One device can be compatible with all types of ball bearing housings within the coverage of its center distance; this device can complete the processing of the bottom surface, positioning boss and mounting hole in one clamping, reducing the transfer inventory of the workpiece and improving the processing efficiency. Specific implementation example figure 1 with figure 2 As shown, the main shaft 2 is installed in the center of the box body. The main shaft 2 is connected to the box body through a bearing. The middle part of the main shaft is sleeved with a sun gear 6, and the upper end of the main shaft is equipped with a boring and milling cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com