Automatic pottery clay pounding machine

A technology of automata and pottery clay, applied to clay preparation devices, clay processing equipment, chemical instruments and methods, etc., can solve the problems of no safety protection, high manufacturing cost, low work efficiency, etc., and achieve reduction of manpower support and land occupation Small area, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

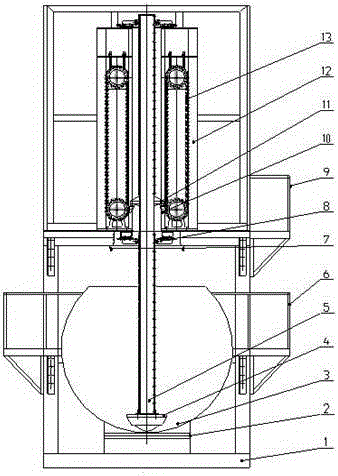

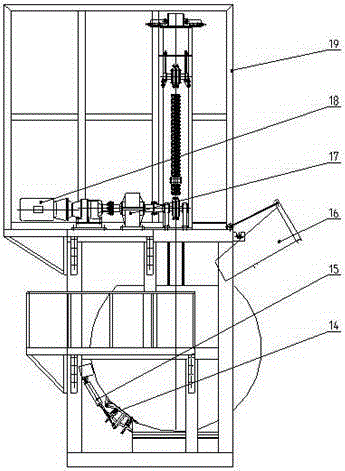

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , figure 2 As shown, the clay automatic machine pestle of the present invention includes a frame 1, a driving device, a lifting device, a pestle bar 5 and a pestle head 4 at the end of the pestle bar 5 . The pestle head 4 is conical, and the bottom is a teat shape smaller than the conical surface. Below the frame 1 is also provided with a spherical hopper 3 with an upper opening, the pestle rod 5 extends into the hopper 3, and the ratio of the diameter of the pestle head 4 to the diameter of the feeding port of the hopper 3 is 7:20. There is a tapered feed hopper 16 on the top of the hopper 3, and the bottom of the hopper 3 is designed with a discharge movable flap 14 driven by the cylinder 15. After the pottery clay is processed, the mud is discharged by the movable flap. The driving device includes a motor 18 , a speed reducer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com