Injection mold for mineral water bottle blank

A technology for injection molds and mineral water bottles, which is applied in the field of molds, can solve problems such as inconvenient installation, low processing efficiency, and poor stability, and achieve the effects of stable installation position, high processing efficiency, and maintaining processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

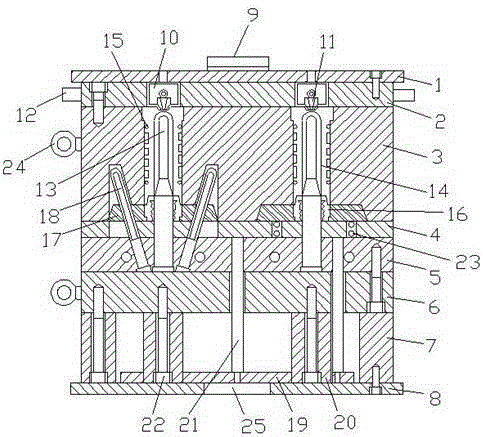

[0018] see figure 1 Shown, a kind of mineral water bottle preform injection mold comprises fixed template 1, runner plate 2, cavity plate 3, push plate 4, movable template 5, movable mold bottom plate 6, mold foot 7 and mold foot plate 8, described The fixed formwork 1, runner plate 2, cavity plate 3, push plate 4, movable formwork 5, movable formwork bottom plate 6, mold foot 7 and mold foot plate 8 are arranged from top to bottom in sequence, and the fixed formwork 1 is provided with pouring Mouth 9, the flow channel plate 2 is provided with a flow divider 10, the flow divider 10 is provided with a nozzle 11, the flow divider 10 communicates with the sprue sleeve 9, and the two ends of the flow channel plate 2 are provided with A heater 12, the heater 12 is connected to the flow divider 10, a mandrel 13 is arranged inside the cavity plate 3, a molded sleeve 14 is arranged outside the mandrel 13, and a sealing ring is arranged on the molded sleeve 14 15. The mold sleeve 14 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com