Induction heater and 3D printing machine extruder

An induction heater, 3D printer technology, applied in the field of 3D printer extruder, induction heater, can solve the problem of heater melting low melting point materials, unable to print glass crystal metal with non-fixed melting point, etc., to achieve uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

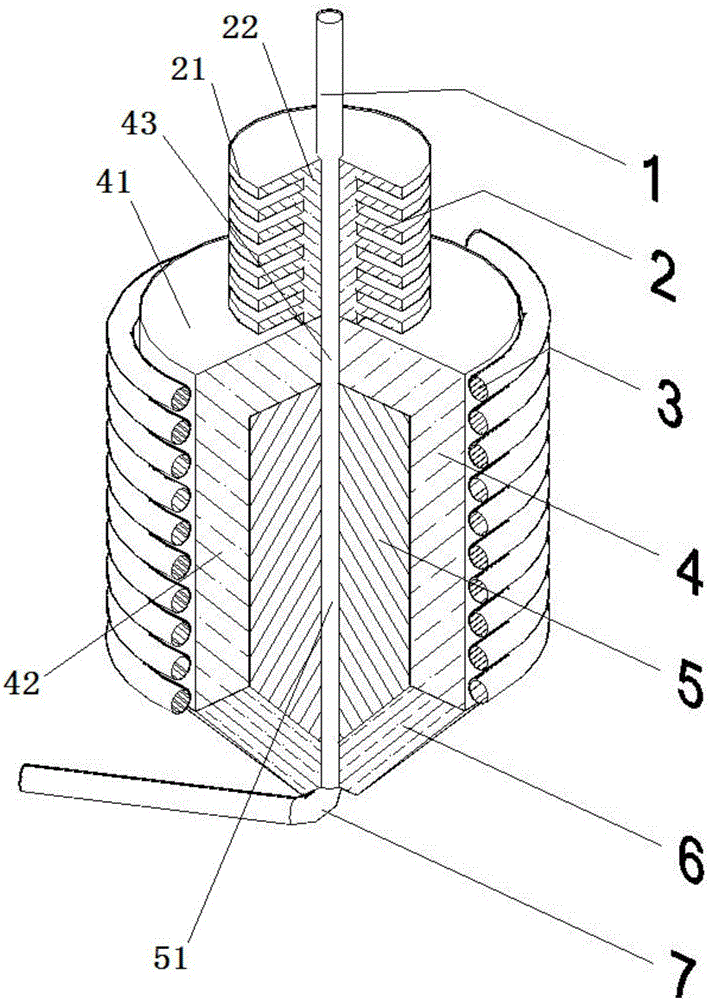

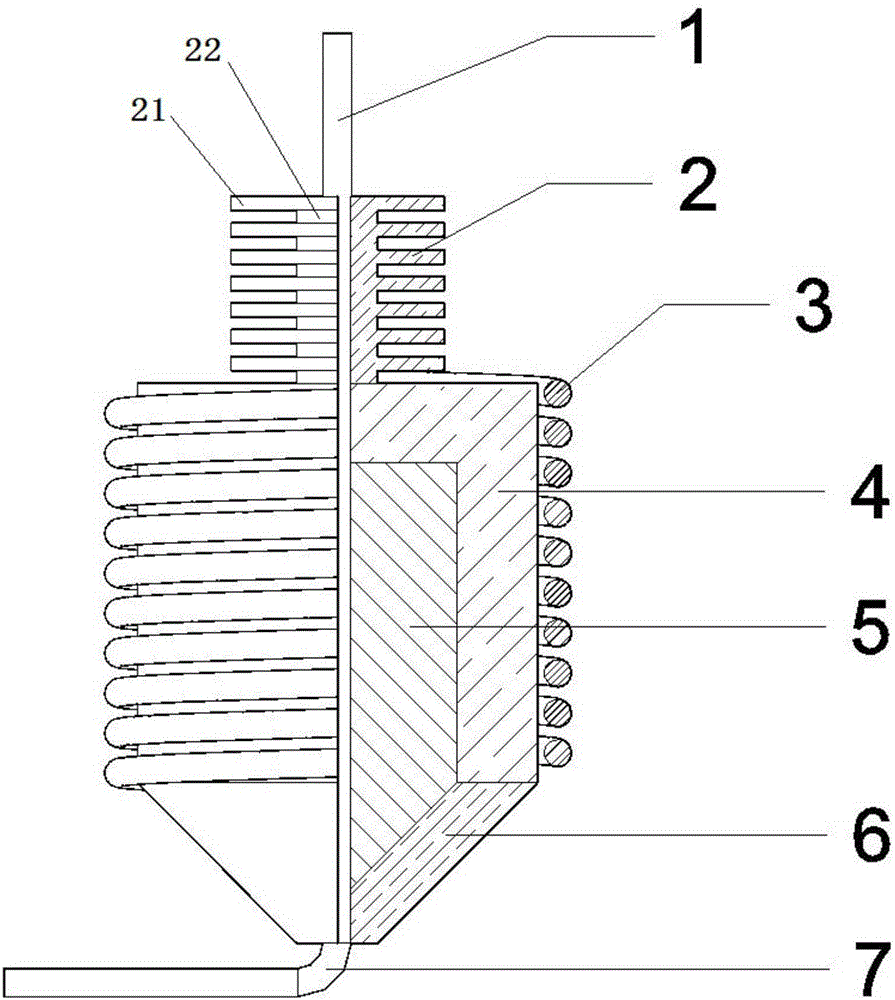

[0031] This embodiment provides an induction heater, which is mainly used for heating material filaments. Such as figure 1 and figure 2 As shown, the heater is mainly composed of a heat shield 4 with a hollow lower end opening formed by connecting the upper bottom wall 41 and the outer peripheral wall 42, an induction coil 3 sleeved on the outer surface of the outer peripheral wall 42, and an eddy current set inside the heat shield 4. The induction heating block 5 is composed of the printing nozzle 6 connected to the lower end of the heat shield. After the printing nozzle 6 is connected with the heat shield 4, a heat insulating cavity is formed to prevent the heat generated by the eddy current induction heating block 5 from overflowing. The inside of the eddy current induction heating block 5 is provided with a through hole 51 that runs through the entire eddy current induction heating block 5. The lower end of the through hole 51 communicates with the printing nozzle 6, an...

Embodiment 2

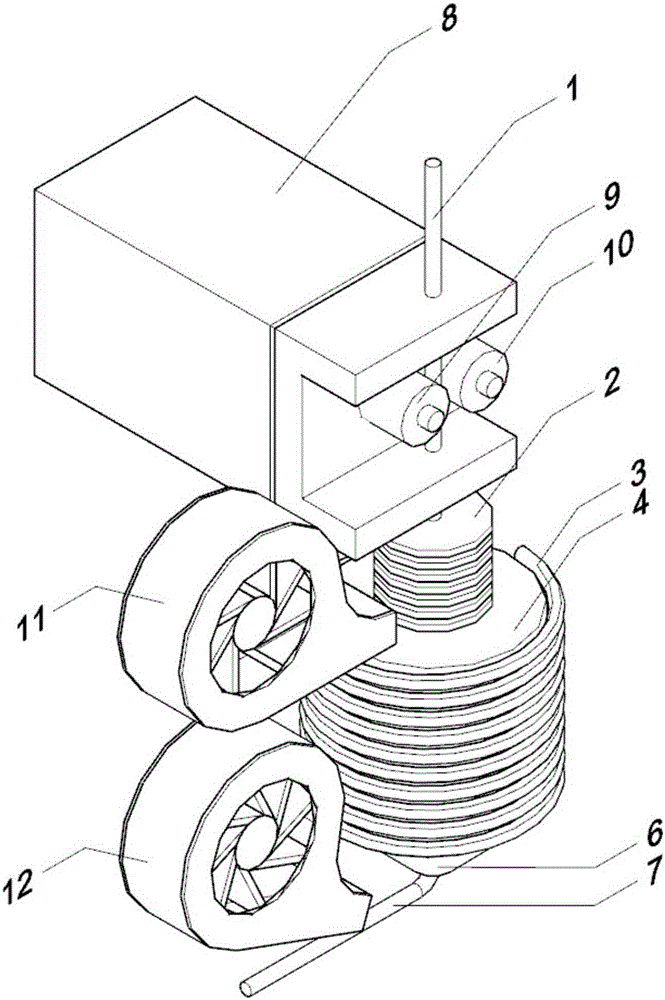

[0041] This embodiment provides a 3D printer extruder, such as image 3 , Figure 4 As shown, the extruder includes the feeding mechanism and the induction heater described in Example 1. The feeding structure is arranged above the induction heater, and feeds the material filament 1 into the through hole 51 of the eddy current induction heating block 5 . If the induction heater is provided with a radiator 2, the material filament 1 enters the interior of the induction heater after passing through the radiator 2.

[0042] The feeding mechanism includes a stepping motor 8, an extrusion wheel 9 and a driven wheel 10, and the rotating shaft of the stepping motor is connected with the extrusion wheel 9. The extrusion wheel 9 cooperates with the driven wheel 10 to squeeze the material filament 1 from between the extrusion wheel 9 and the driven wheel 10 into the through hole 51 of the eddy current induction heating block 5 .

[0043] Among the components in contact with the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com