Energy-saving ship capable of efficiently decomposing resistance

A resistance and high-efficiency technology, applied in ship propulsion, ship parts, ship construction, etc., can solve the problems of small navigation resistance, easy overturning of ships, difficult maintenance or replacement of propellers, etc., and achieve the effect of ensuring navigation and low navigation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

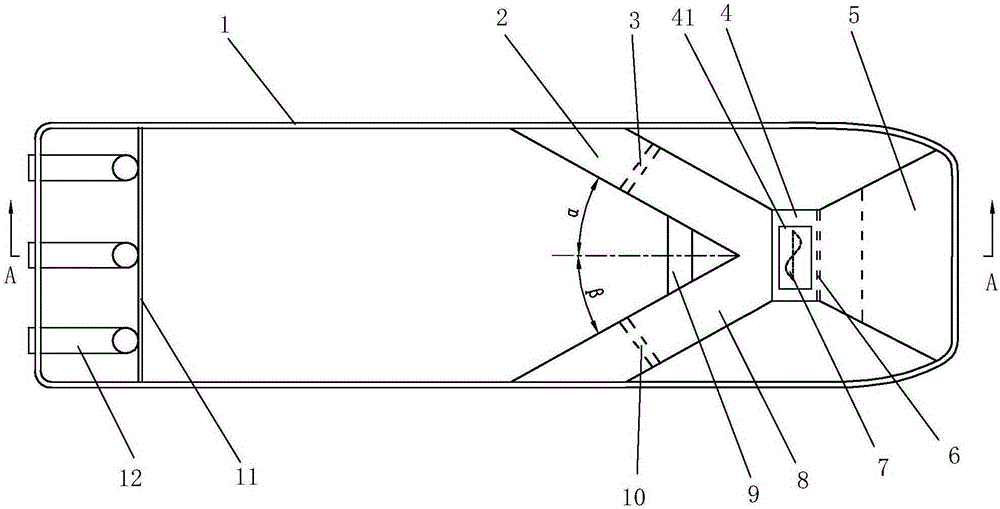

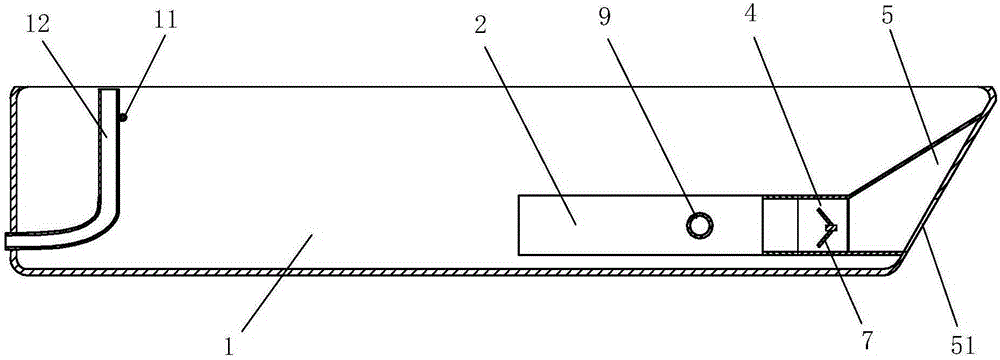

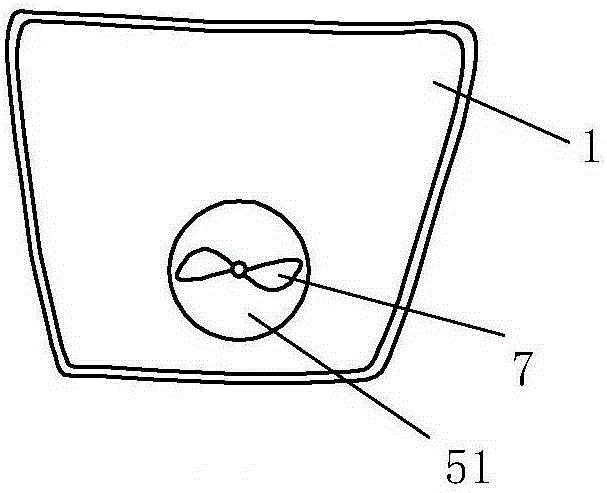

[0026] Embodiment 1: A kind of high-efficiency decomposition resistance energy-saving ship, such as Figure 1-Figure 3 As shown, it includes a hull 1 and a propeller, and the propeller includes a DC propeller 7, and the bilge of the hull 1 is provided with a bow suction horn 5, a connecting pipe 4, a left drainage channel 2 and a right drainage channel 8 , the DC propeller 7 is installed in the connecting pipe 4, the connecting pipe is connected and communicated with the bow water suction bell mouth 5, the water inlets of the left drainage channel 2 and the right drainage channel 8 are connected and communicated with the connecting pipeline 4, and the left drainage The water outlet of the channel is located on the left side of the hull, and the water outlet of the right drainage channel is located on the right side of the hull. A left valve 3 is arranged in the left drainage channel. The left valve is used to control the opening and closing of the left drainage channel 2 and ad...

Embodiment 2

[0030] Embodiment 2: A kind of high-efficiency decomposition resistance energy-saving ship, such as Figure 4As shown, its basic structure is the same as that of Embodiment 1, the difference is that the propeller also includes a left vortex propeller 13 and a right vortex propeller 16, and the left vortex propeller 13 is installed on the bow water suction horn 5 on the left side and communicates with the left drainage channel 2 through the left pipeline 15, and the right vortex propeller 16 is installed on the right side of the water suction bell mouth 5 of the bow and communicates with the right drainage channel 8 through the right pipeline 18. The water inlet of the left vortex propeller 13 is provided with a water inlet and outlet valve 20 of the left vortex propeller, and a valve I 14 is arranged in the left pipeline 15, and the valve I is used to control the opening and closing of the left pipeline 15 and adjust the water flow. The vortex propeller 16 is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com