Method of cracking excess sludge with γ-ray combined with modified fly ash

A technology for excess sludge and fly ash, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult industrialization and application, long cracking time, and low utilization rate. , to achieve the effect of facilitating industrialization, reducing environmental pollution and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

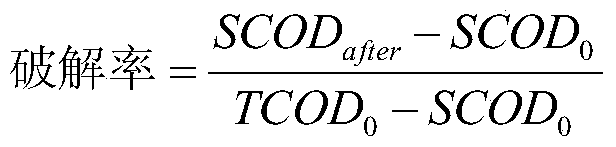

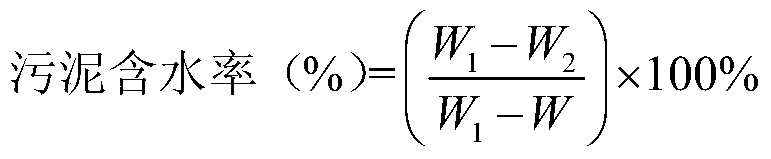

Method used

Image

Examples

Embodiment 1

[0026] (1) Sampling of fly ash and excess sludge:

[0027] The fly ash is taken from the power plant; the remaining sludge is taken from the secondary sedimentation tank of the sewage treatment plant. The water content of the remaining sludge is about 98%-99%, and it is stored at a constant temperature of 4°C until use.

[0028] (2) Preparation of modified fly ash cracking agent:

[0029] Prepare a sodium hydroxide solution with a concentration of 4mol / L, mix the fly ash and the sodium hydroxide solution according to the solid-to-liquid ratio (g / mL) of 1:1, stir well at room temperature, let stand for 3 hours, and bake at 100°C Dry and grind until the particle size is below 2mm, and set aside.

[0030] (3) cracking reaction:

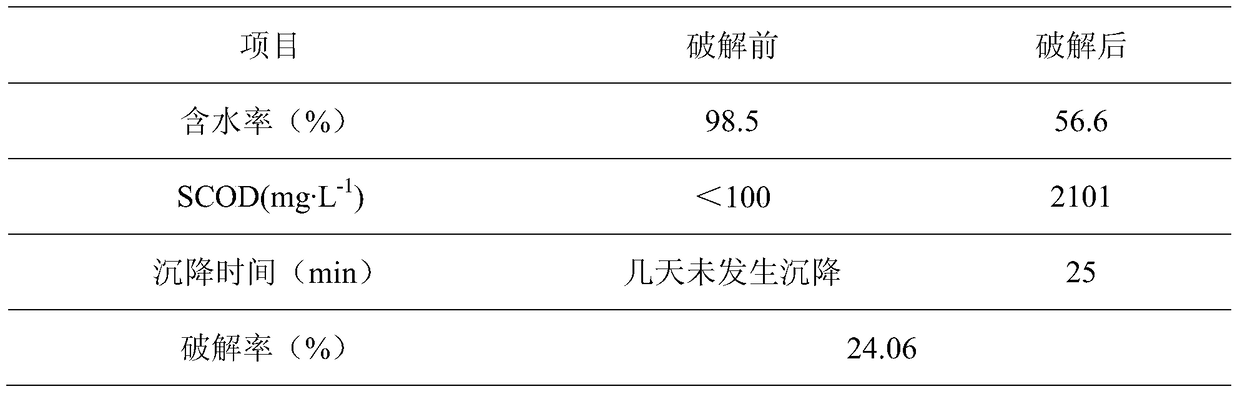

[0031] Take 100mL of excess sludge, add 2g of modified fly ash to it, put it into a 200mL reactor, and stir it fully to obtain sludge slurry. Uniformly irradiate the reactor containing excess sludge and modified fly ash with γ-rays, using an irradiati...

Embodiment 2

[0048] (1) Sampling of fly ash and excess sludge is the same as in Example 1.

[0049] (2) Preparation of modified fly ash cracking agent:

[0050]Prepare a sodium hydroxide solution with a concentration of 4mol / L, mix the fly ash and the sodium hydroxide solution according to the solid-liquid ratio (g / mL) of 1:2, stir well at room temperature, let stand for 3.5 hours, and bake at 100°C Dry and grind until the particle size is below 2mm to obtain modified fly ash;

[0051] (3) cracking reaction:

[0052] Take 100mL of excess sludge, add 4g of modified fly ash to it, put it into a 200mL reactor, and stir it thoroughly to obtain sludge slurry. use 60 Coγ-rays were used to uniformly irradiate the reactor containing excess sludge and modified fly ash, with an irradiation dose of 3 kGy, and then irradiated at room temperature for 20 minutes. After the reaction was completed, the reactor was taken out, and the remaining sludge mixture was centrifuged at 2500r / min for 20min to de...

Embodiment 3

[0058] (1) Sampling of fly ash and excess sludge is the same as in Example 1.

[0059] (2) Preparation of modified fly ash cracking agent:

[0060] Prepare a sodium hydroxide solution with a concentration of 4mol / L, mix the fly ash and the sodium hydroxide solution according to the solid-to-liquid ratio (g / mL) of 1:3, stir well at room temperature, let stand for 4 hours, and bake at 100°C Dry and grind until the particle size is below 2mm to obtain modified fly ash;

[0061] (3) cracking reaction:

[0062] Take 100mL of excess sludge, add 6g of modified fly ash to it, put it into a 200mL reactor, and stir it thoroughly to obtain sludge slurry. Uniformly irradiate the reactor containing excess sludge and modified fly ash with γ-rays at a dose of 5 kGy, and then irradiate at room temperature for 30 minutes. After the reaction was completed, the reactor was taken out, and the remaining sludge mixture was centrifuged at 2500r / min for 20min to detect and analyze the solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com