Stilling well for connecting vertical shaft with recession tunnel

A stilling well and water receding technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of strong splashing and ejection of water flow, and achieve the effects of reducing momentum exchange, reducing height, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

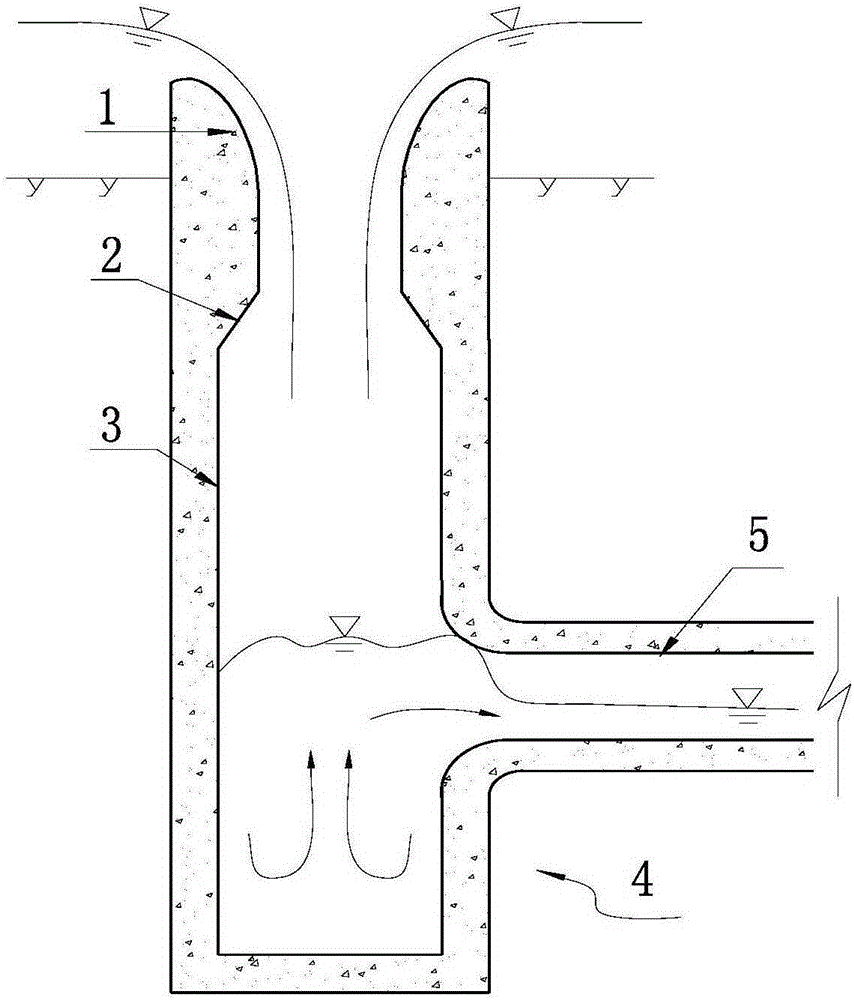

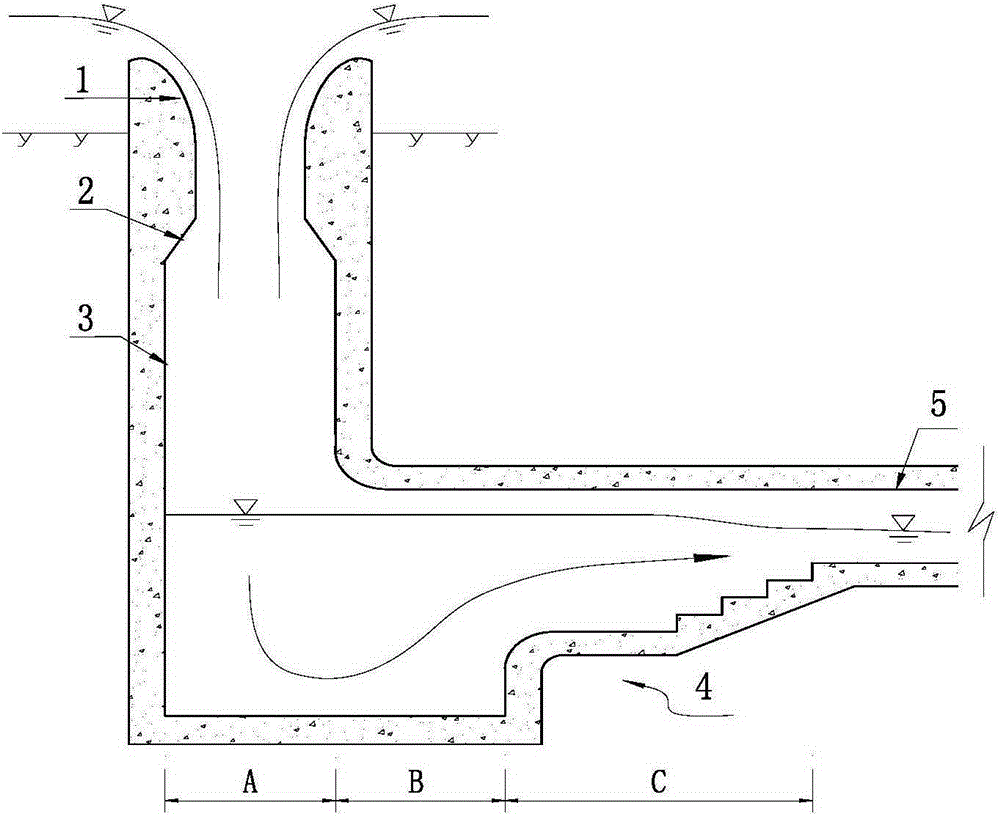

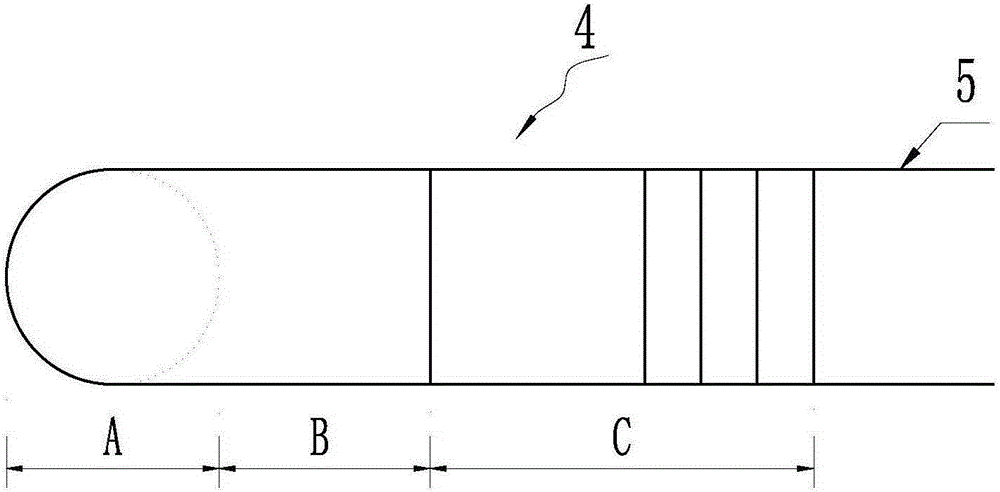

[0028] Such as figure 2 , image 3 As shown, the stilling well 4 is included in this embodiment, the water inlet end of the stilling well 4 is connected to the water outlet end of the shaft 3, and the water inlet end of the shaft 3 is connected to the bottom of the overflow weir 1 through the transition section 2, The stilling well 4 is provided with a splashing section A, a buffer section B and an adjusting section C, which are connected in sequence, and the bottom plate elevation of the stilling well adjusting section C is higher than that of the buffer section B , a step is formed on the vertical plane, the first half of the adjustment section C is a horizontal plane, the second half is a ladder type, and the end is connected with the retreating tunnel 5 .

[0029] Such as Figure 4 with Figure 5 As shown, when the width of the stilling well 4 is inconsistent with the width of the water retreat tunnel 5, the adjustment section C is connected with the water retreat tunn...

Embodiment 2

[0032] Such as Image 6 As shown, the adjusting section C of the stilling well in this embodiment has a stepped slope structure as a whole, and the rest of the structure is similar to that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0034] Such as Figure 7 As shown, the adjusting section C of the stilling well in this embodiment has a slope structure as a whole, and the rest of the structure is similar to that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com