Silencing slice

A technology of sound-absorbing sheet and sound-absorbing material, which is applied in the field of acoustics, can solve problems such as the leakage quality of the sound-absorbing sheet fiber, and achieve the effects of saving manpower and material resources, light weight, and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In view of the fact that the sound-absorbing sheets in the prior art are mostly made of metal perforated plates as the covering material, the interior is filled with glass fibers. Although this method can reduce airflow noise, there is still the problem of glass fiber leakage, it is not suitable for occasions with high cleanliness requirements, and there are disadvantages such as high quality and difficult installation.

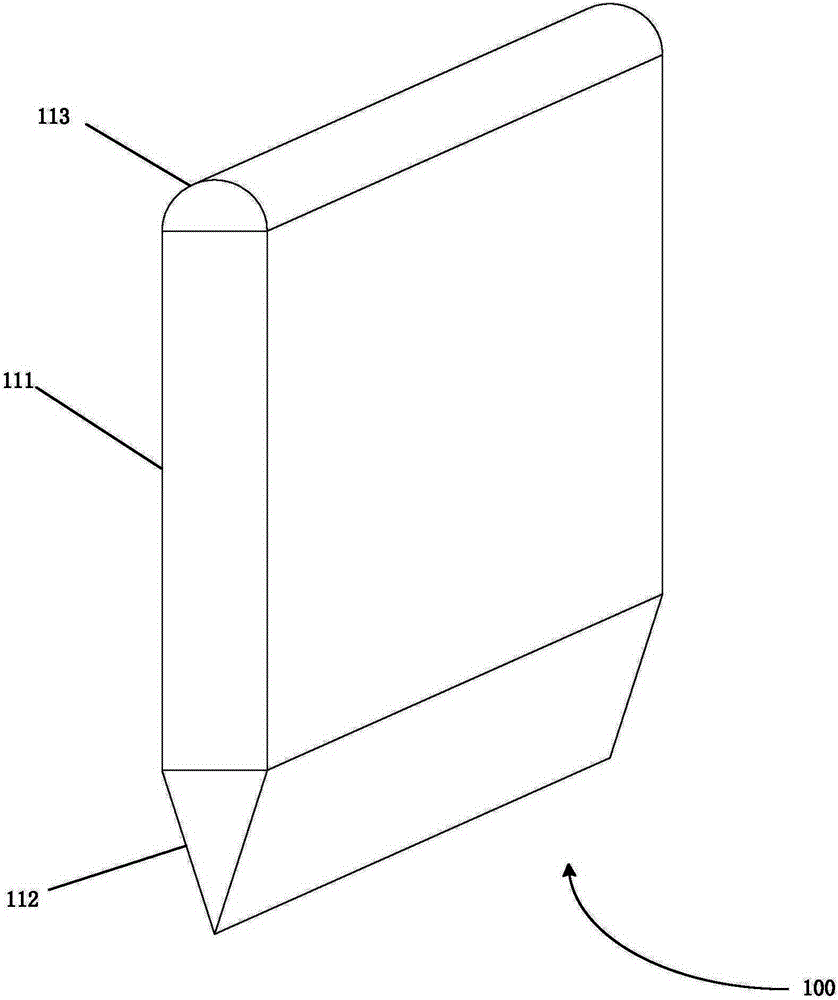

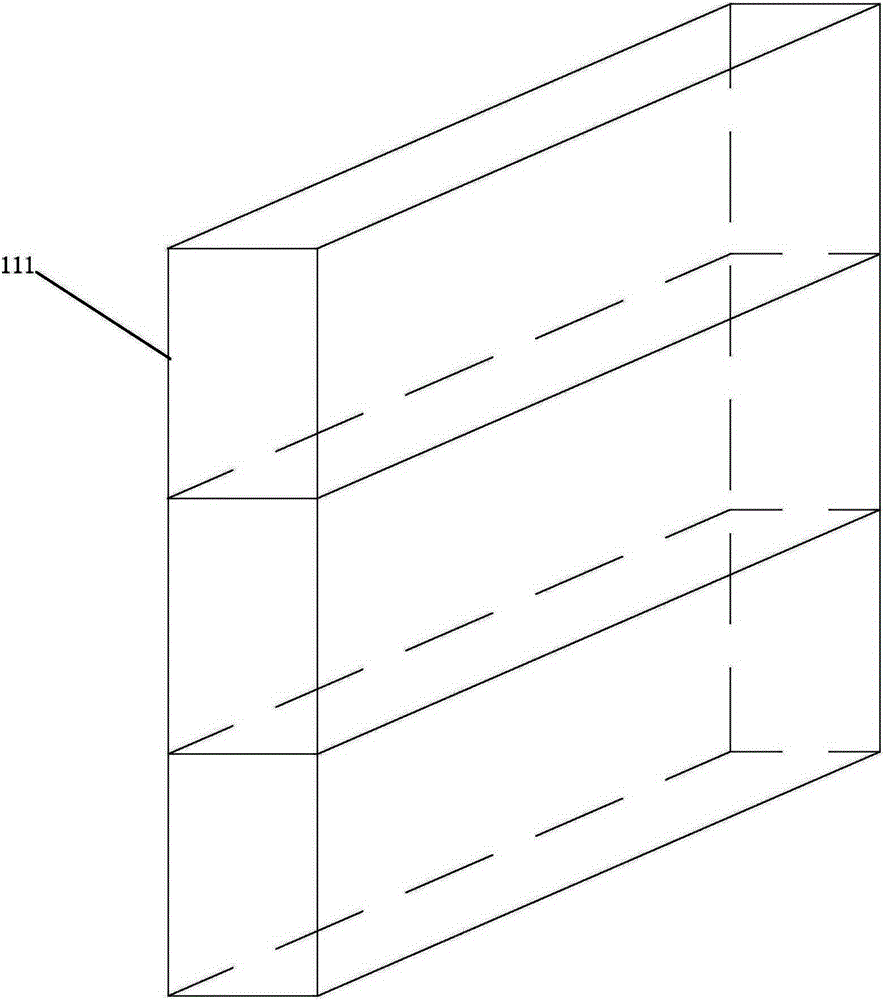

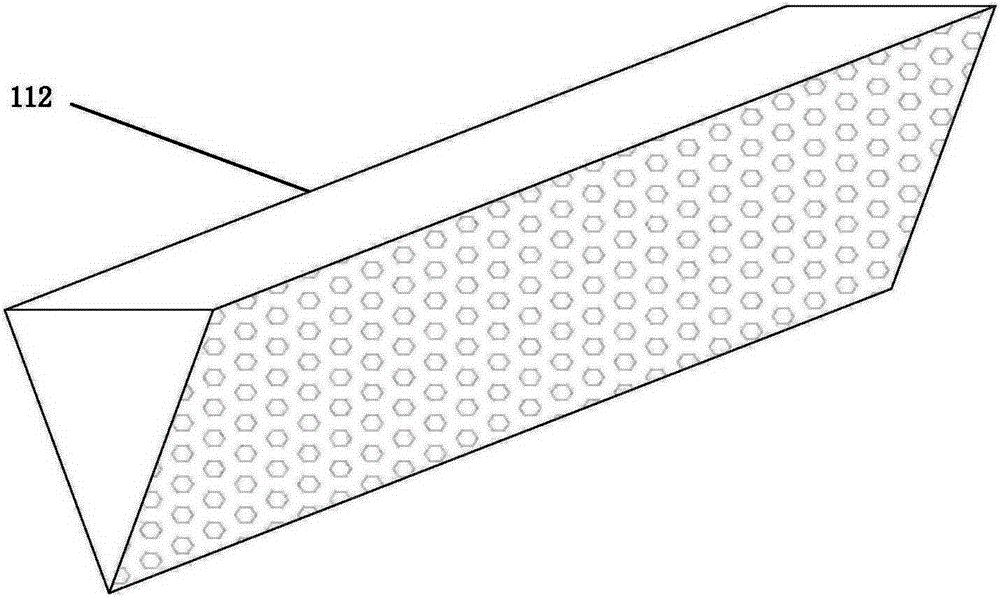

[0023] Based on this, this patent has designed a novel sound-absorbing sheet. The structural frame of the muffler consists of three parts: 1. The frame body is welded by metal materials; 2. The diversion cap at one end of the frame body is an arc-shaped structure, and the arc-shaped structure is processed by metal plates; , It is a wedge-shaped structure at the other end of the main body of the frame. The entire frame is processed by metal structure, which has sufficient strength. Compared with the metal perforated plate structure muffler, it has the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com