In-situ tensile sample for transmission electron microscope and preparation method of in-situ tensile sample

A technology of in-situ stretching and transmission electron microscopy, applied in the field of materials science, can solve problems such as low success rate and low technical efficiency, and achieve high success rate, wide application range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1. Prepare standard substrates for in-situ tensile specimens.

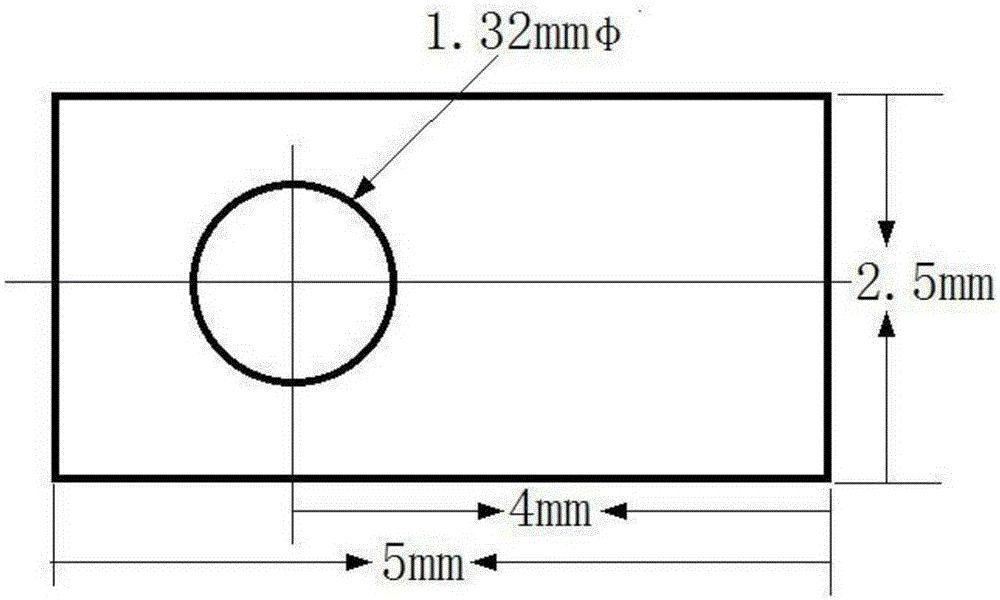

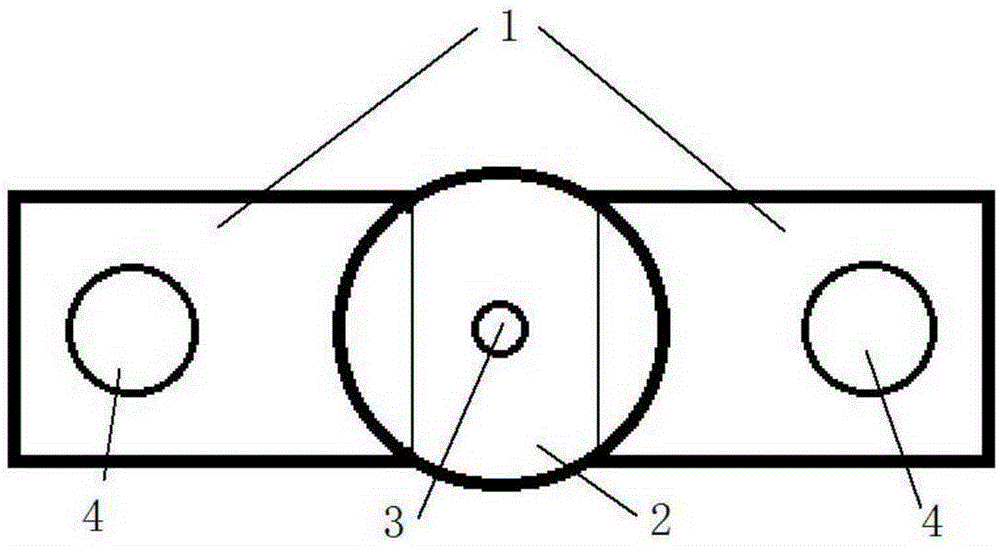

[0033] The base sheet 1 is produced by using the can skin, and a circular hole 4 with a diameter of 1.32 mm is opened on the top, and the sample is stretched in a fixed position to a fixed position on the sample stretching sample stage.

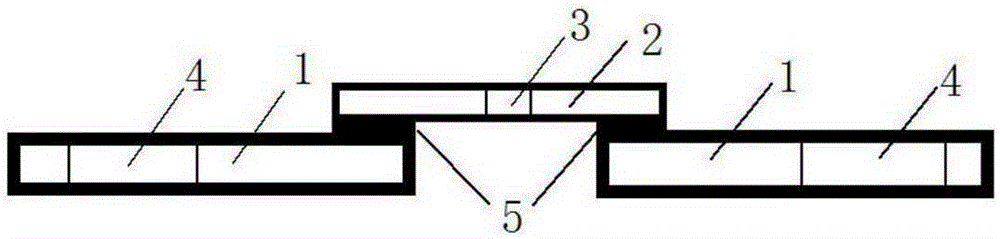

[0034] 2. Prepare a standard TEM sample 2. After double-jet electrolytic polishing, a hole 3 appears in the center of the sample, and the edge of the hole is the thin area observed in situ.

[0035] 3. Use the AB glue 5 to paste the standard TEM sample 2 on the two substrates 1 in a bridging manner (the gap between the two substrates is 1-2mm). AB glue 5 is evenly applied to the overlapping area between the standard electron microscope transmission sample 2 and the two standard substrates 1 , and then the sample 2 is placed on the two substrates 1 .

[0036] 4. After standing and curing the sample after the above step 3 for 2 hours, the in-situ tensile sample of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com