A simple grinding tool

An abrasive tool and simple technology, which is applied in the preparation of test samples, etc., can solve the problems of high abrasive tool quality, affecting operations, and difficult manpower to operate for a long time, and achieves the effect of light weight, simple structure, and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a simple abrasive tool.

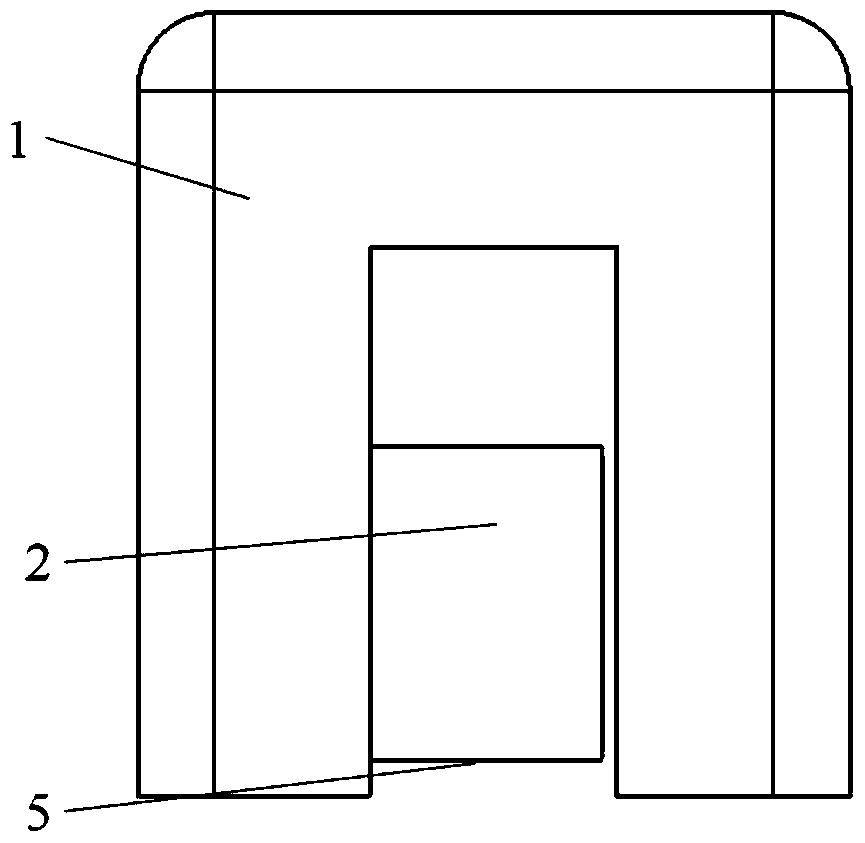

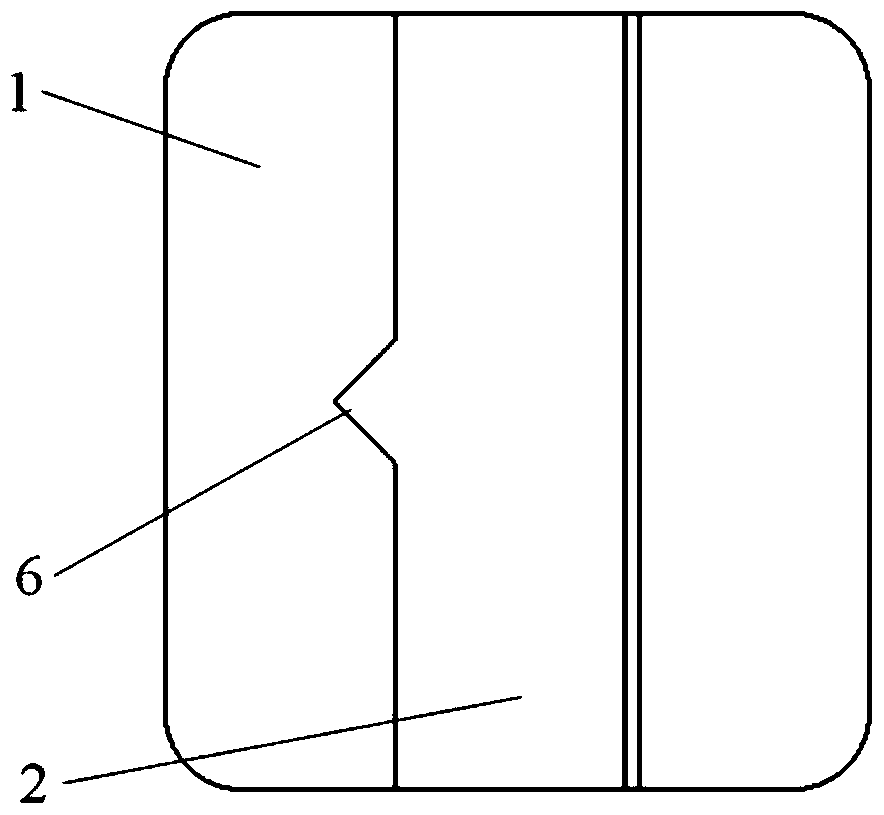

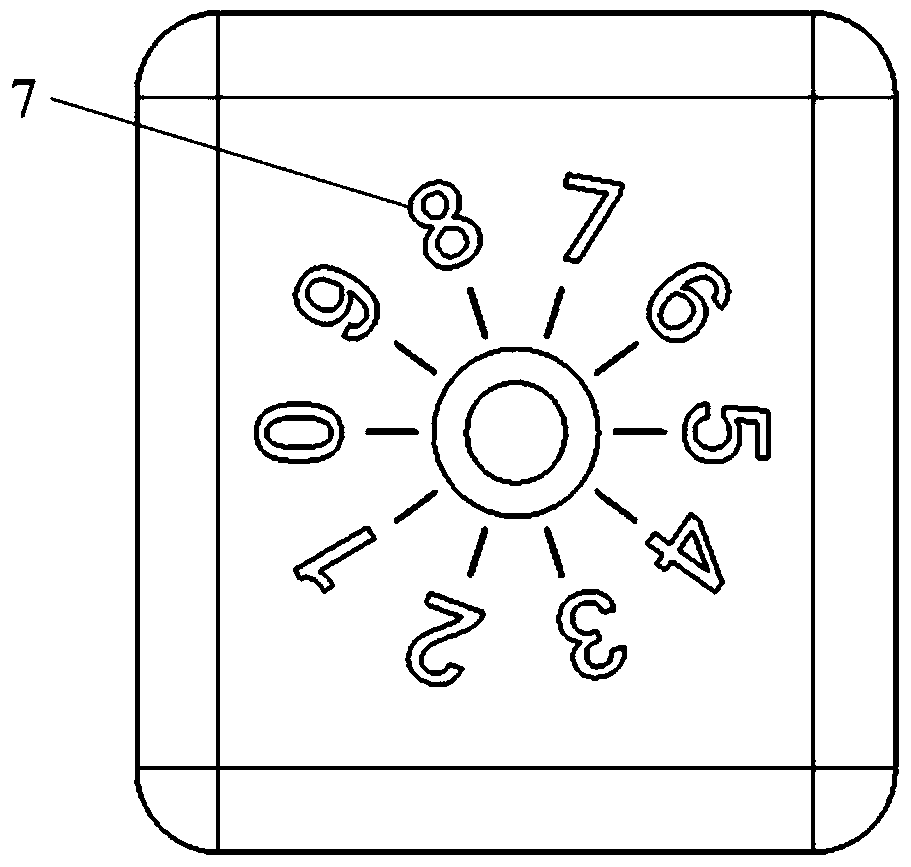

[0021] Refer to Figure 1 ~ Figure 6 , The simple abrasive tool of this embodiment is composed of abrasive tool base 1, pressing slider 2, positioning fastening bolt 3, position control bolt 4, guide chute 6, position control dial 7; abrasive base 1 is a rectangular body, The bottom of the abrasive tool base 1 is provided with grooves on both sides of the abrasive tool base 1, and there is a guide chute 6 along the vertical direction of the middle of the inner wall of the groove. The guide chute 6 is either equilateral right angle or semicircular arc shape. Kind. The upper part of the abrasive tool base 1 has rounded corners, and the center of the upper surface of the abrasive tool base 1 is provided with a stepped screw hole communicating with the groove, and an equally divided position control dial 7 is arranged along the center of the screw hole. The abrasive tool base 1 is in the groove Two symmetrical stepped screw holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com