Ladder sliding channel four-side sliding bead coplanar aluminum alloy fixing device

An aluminum alloy, the same plane technology, applied in the field of glass testing fixtures, can solve the problems of long time, inconvenient operation, waste and pollution, etc., to achieve the effect of ensuring personal safety, improving work efficiency, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

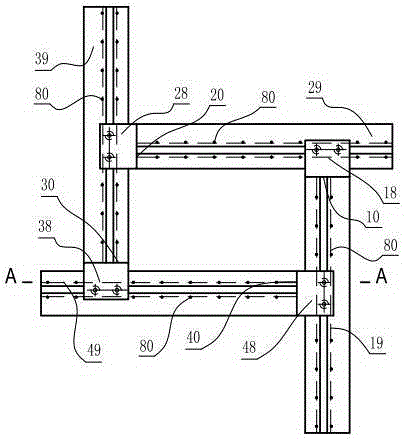

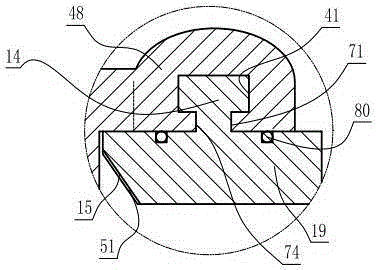

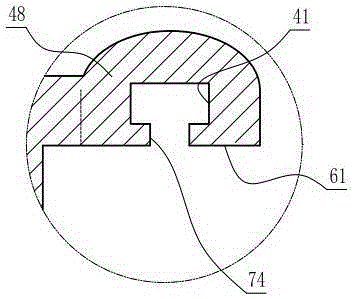

[0039] figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 9 , Figure 10 , Figure 11 with Figure 12 Middle: The four-side sliding balls on the ladder slideway are on the same plane as the aluminum alloy fixing device, including four first pressing plates 10, second pressing plates 20, third pressing plates 30 and fourth pressing plates 40 with the same structural size, each pressing plate consists of a fixed part and a sliding plate The first pressing plate 10 is composed of the first fixed part 19 and the first sliding part 18, the second pressing plate 20 is composed of the second fixing part 29 and the second sliding part 28, and the third pressing plate 30 is composed of the third fixed part part 39 and the third slide part 38, the fourth platen 40 is composed of the fourth fixed part 49 and the fourth slide part 48; ; As an imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com