Crystal silicon solar battery dry etching clamp

A solar cell and dry etching technology, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of uneven application of force at two points, uneven force, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

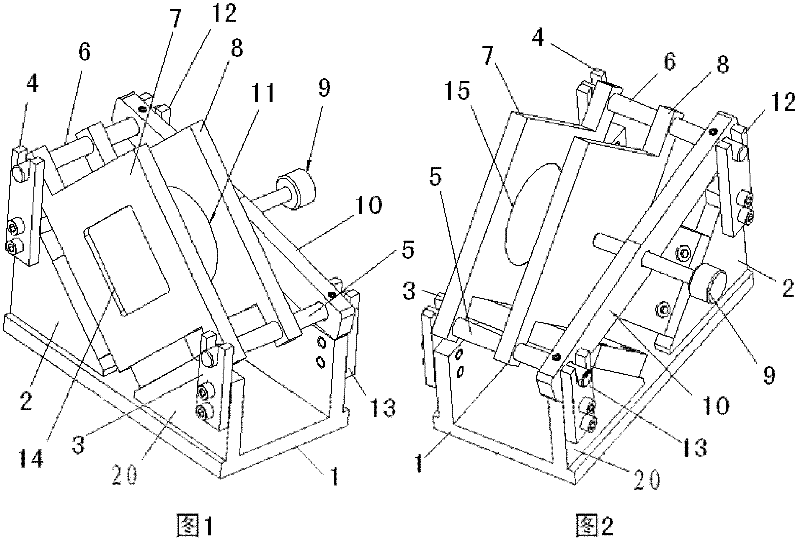

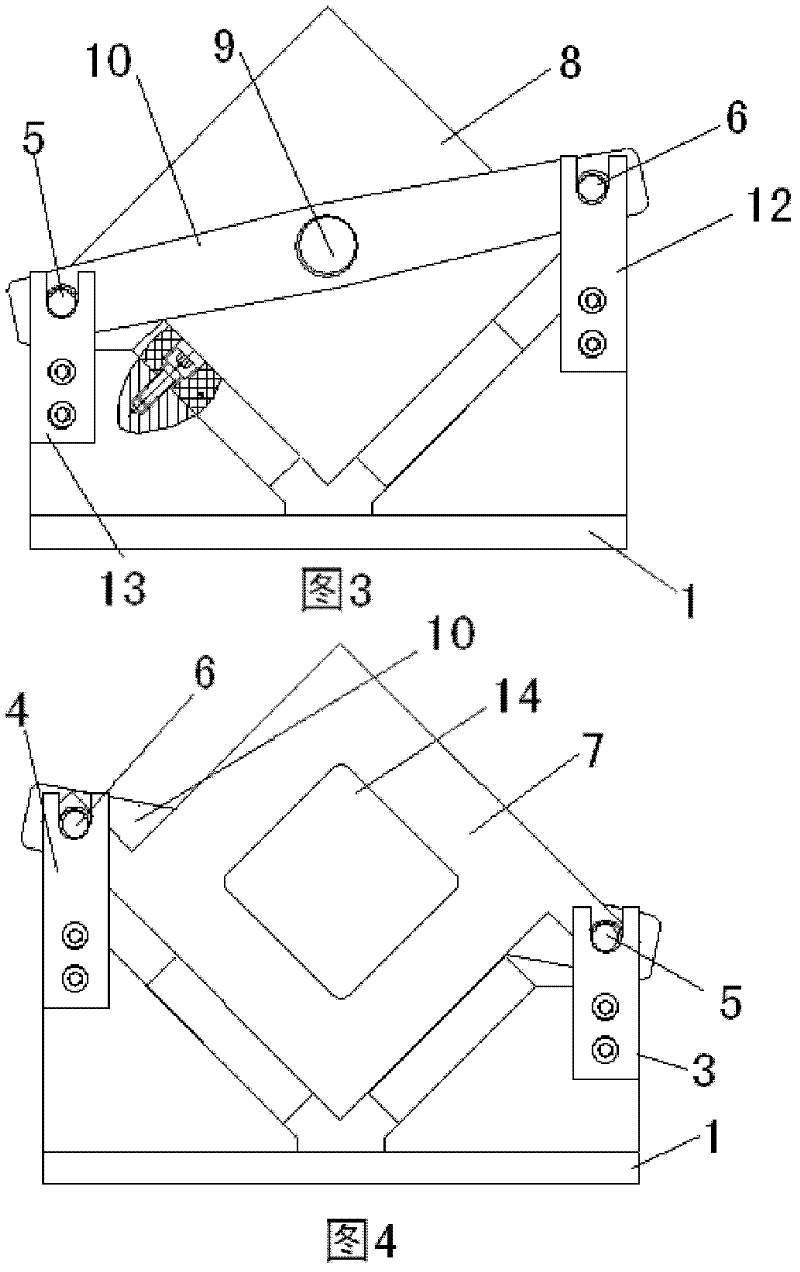

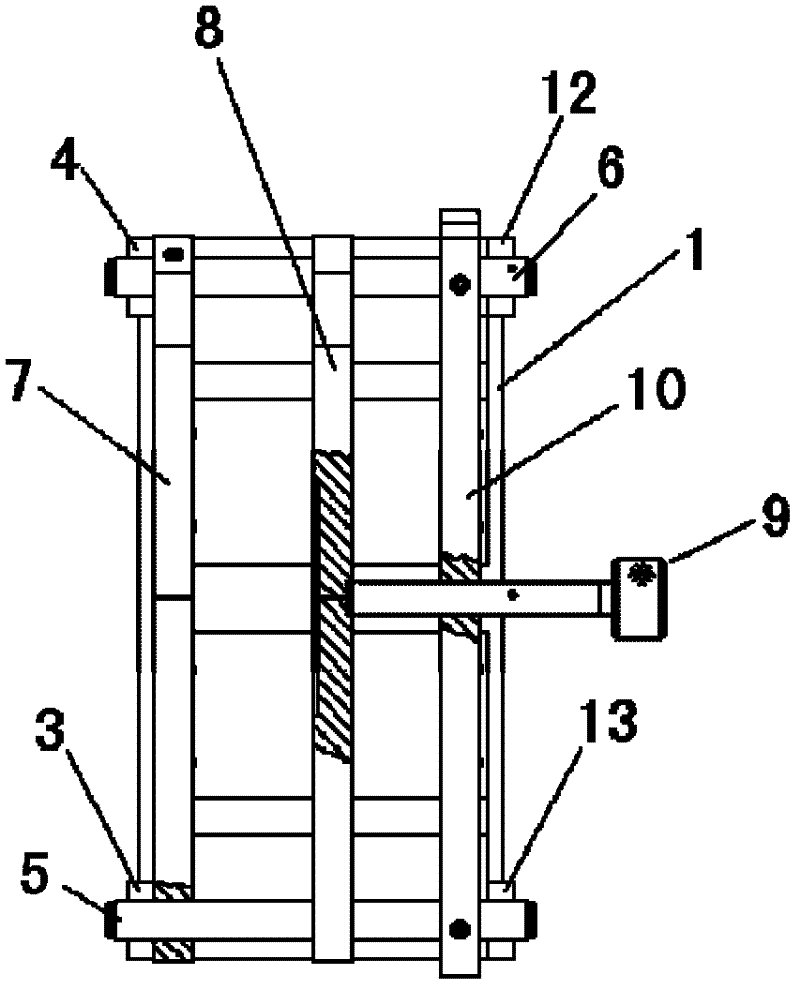

[0042] The present invention provides a fixture for dry etching of crystalline silicon solar cells, which includes a fixed splint 7, a movable splint 8, a screw 9, a silicon chip stacking base 2, a bottom plate 1, a first support seat 3, a second support seat 4, The third support seat 12, the fourth support seat 13, the ejector rod 9, the ejector rod support 10, the first support shaft 5, and the second support shaft 6;

[0043] The bottom plate 1 is connected to the silicon wafer stacking base 2; the two side walls of the first silicon wafer stacking base 2 are fixedly connected with the first supporting base 3 and the fourth supporting base 13 by bolts respectively; the two sides of the second silicon wafer stacking base 20 On the side wall, the third support seat 12 and the second support seat 4 are fixedly connected by bolts respectively; the upper ends of the first support seat 3, the second support seat 4, the third support seat 12 and the fourth support seat 13 have gaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com