Toughened glass fragment test immobilization method

A technology of tempered glass and fixing method, which is applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by using one-time impact force, which can solve the problems of glass shards splashing, operator injury, and long time-consuming, so as to avoid environmental pollution and personal safety The effects of security and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

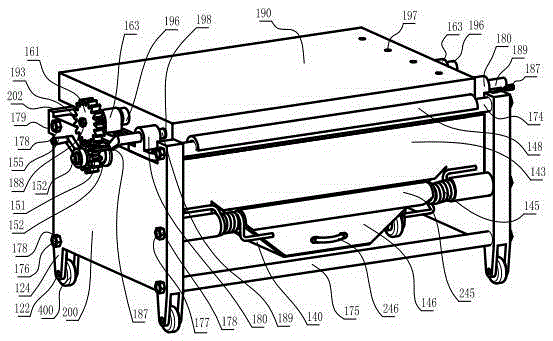

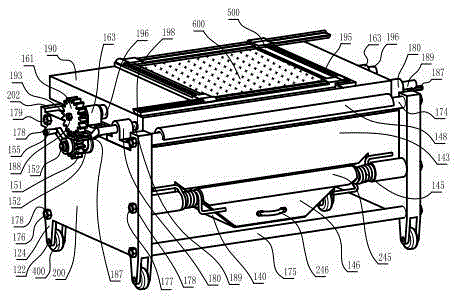

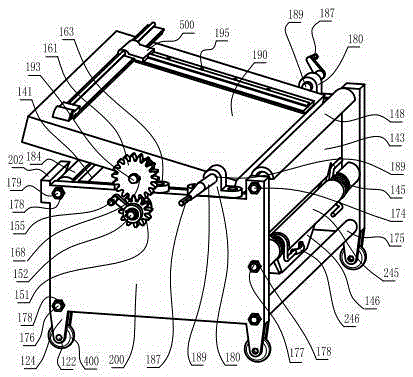

[0051] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 10 and Figure 12 Middle: A method for testing and fixing tempered glass shards. The testing equipment used includes: a test bench 190 and a plate frame 200, and between the two plate frames 200 there is a frame front upper pull rod 174 and a frame front pull rod 175 And pull-down bar 176 and frame back pull-up bar 179 after frame; Described test plate 190 both sides have platen rotating shaft 196, also be fixed with transmission gear 161 on the platen rotating shaft 196 of one side, transmission gear 161 cooperates Manual gear 151, manual gear 151 is rotatably fixed on the manual wheel shaft 152; Stud lock pin 189 external thread is matched with lock pin support 180 inner hole thread, and lock pin support 180 is fixed on the plate frame 200 upper plane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com