Evaluation method for jointed rock performance and bolting and grouting effects under compression-shear condition

A jointed rock mass and evaluation method technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., can solve the problem of deviation of rock mechanical parameters, inaccurate measurement data, The position of the test piece is prone to problems such as slippage, and the accuracy is easy to ensure, the test error is reduced, and the bending moment is avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

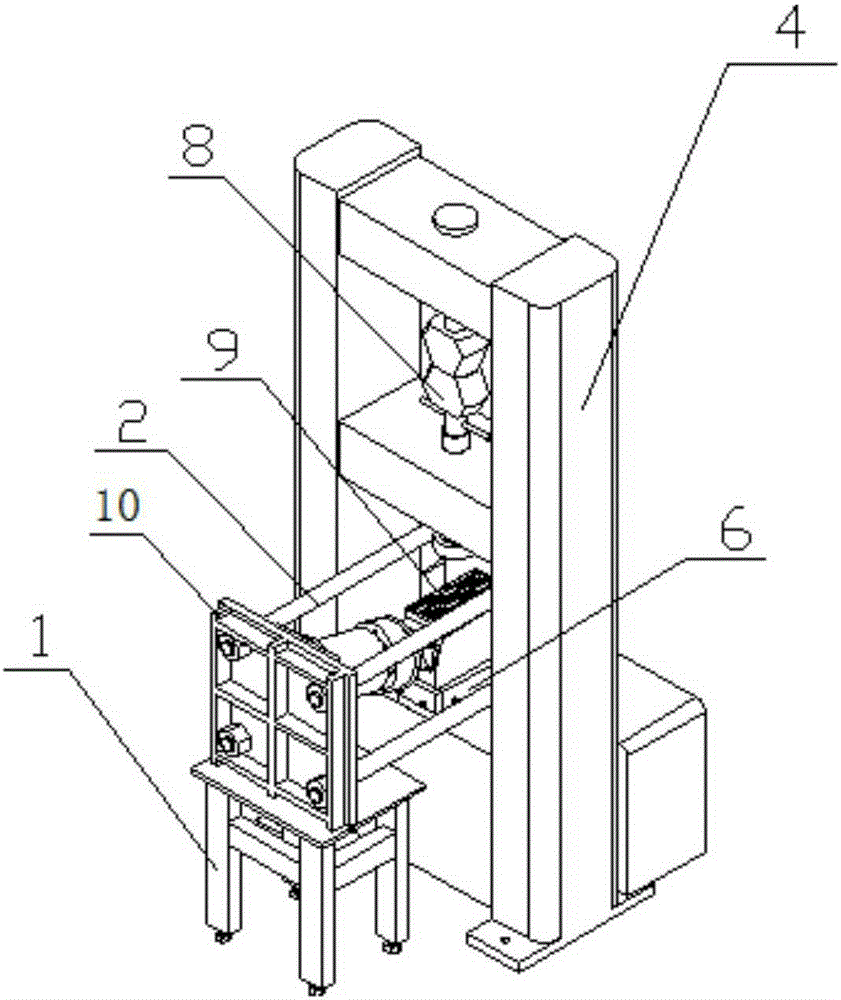

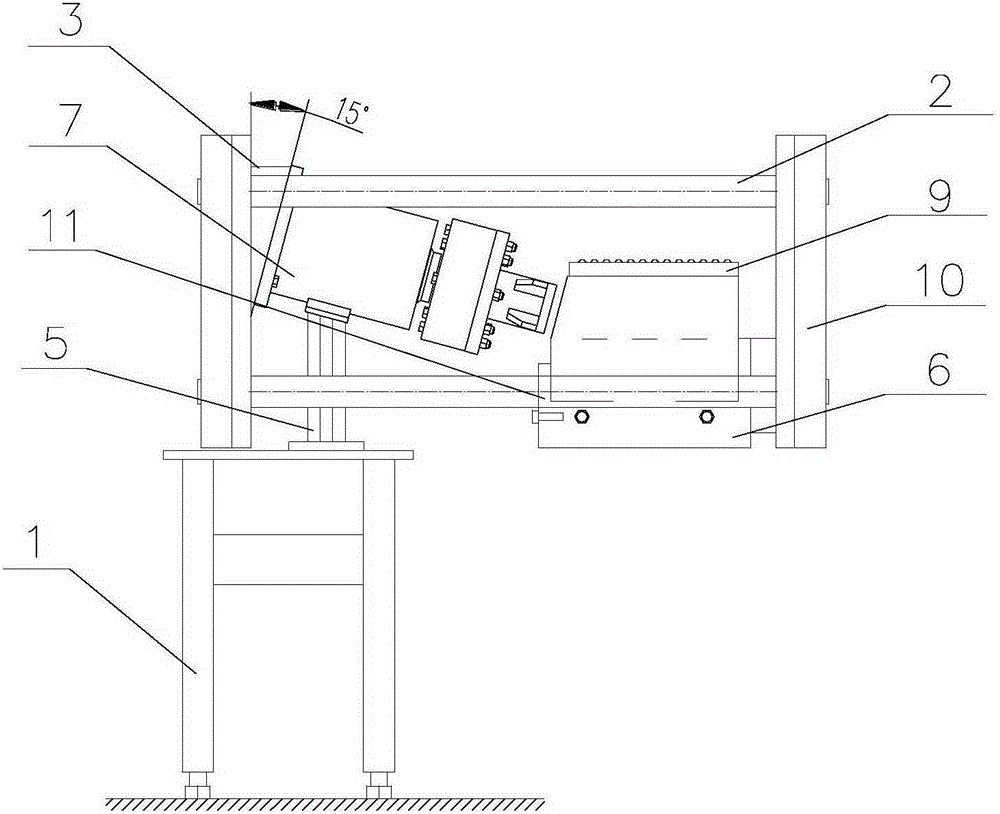

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

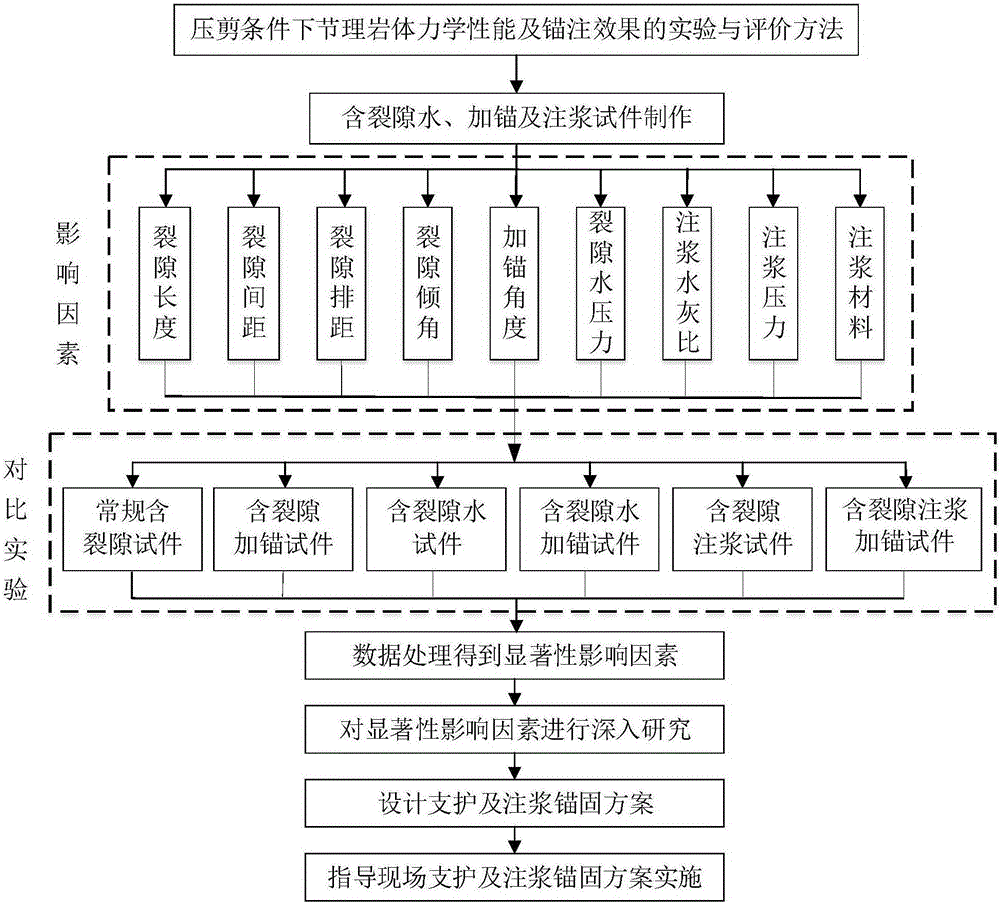

[0071] The experiment and evaluation method of the mechanical properties of jointed rock mass and anchor grouting effect under compression and shear conditions, taking the grouting and anchor test with cracks as an example, includes the following steps:

[0072] Step 1: Determine the factors that affect the rock mass compression-shear performance and anchor grouting effect, such as grouting pressure, grout-water-cement ratio, inclination angle of anchor rod, etc., and determine the level of each factor used in the test according to the experience level of each factor , for example, there are a levels of grouting pressure, b levels of grout water-cement ratio, and c levels of bolt inclination angle, select the appropriate orthogonal table according to the number of factors and levels, and then design the table header to complete the orthogonal experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com