A helium-doped modified lithium iron phosphate thin film positive electrode material and preparation method thereof

A thin-film cathode, lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of limited improvement in electrochemical properties of materials, small size influence, and many processes, and shorten the preparation time. , The effect of improving productivity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

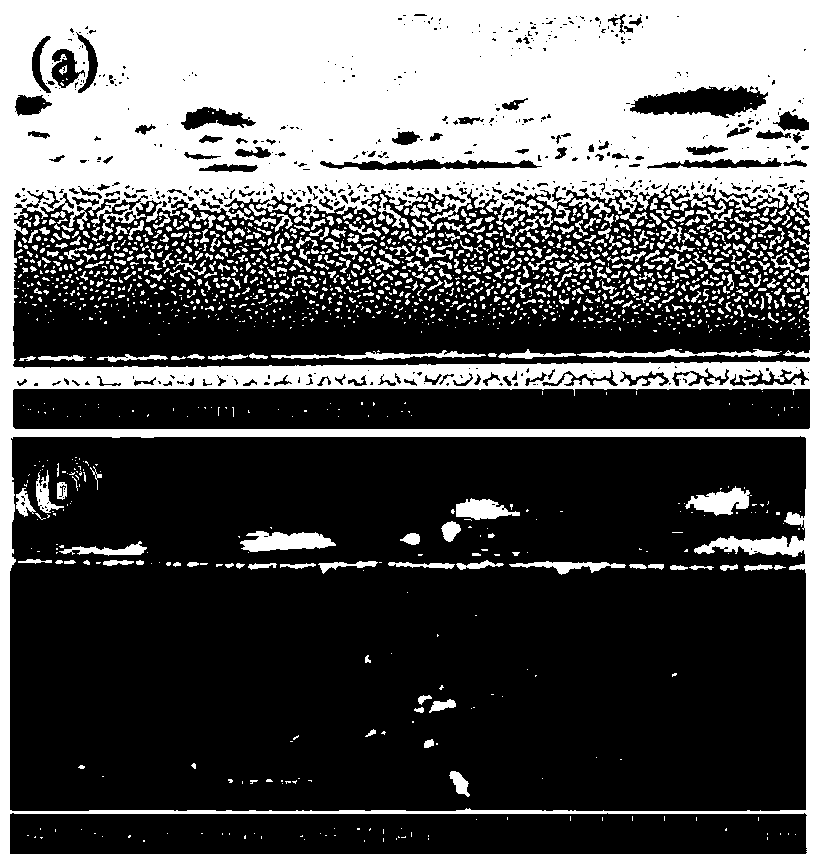

[0030] (1) Place the cleaned 316 stainless steel sheet in a magnetron sputtering vacuum chamber with a background vacuum pressure of 9.0×10 -4 Pa, under the sputtering power of 40W, carry out radio frequency magnetron sputtering coating, with a purity of not less than 99.95wt% ceramic LiFePO 4 The target is used as a sputtering source, and a mixed gas of Ar and He is introduced at the same time during sputtering, wherein the pressure of Ar is 0.8Pa, the gas pressure ratio of Ar and He is 10:1, and the sputtering deposition time is 20min;

[0031] (2) LiFePO obtained in step (1) 4 / He thin film cathode material was annealed in a high vacuum annealing furnace, the annealing temperature was 300°C, and the annealing pressure was 9.0×10 -4 Pa, annealed for 1 hour, after the annealing is completed, cool with the furnace and come out of the furnace.

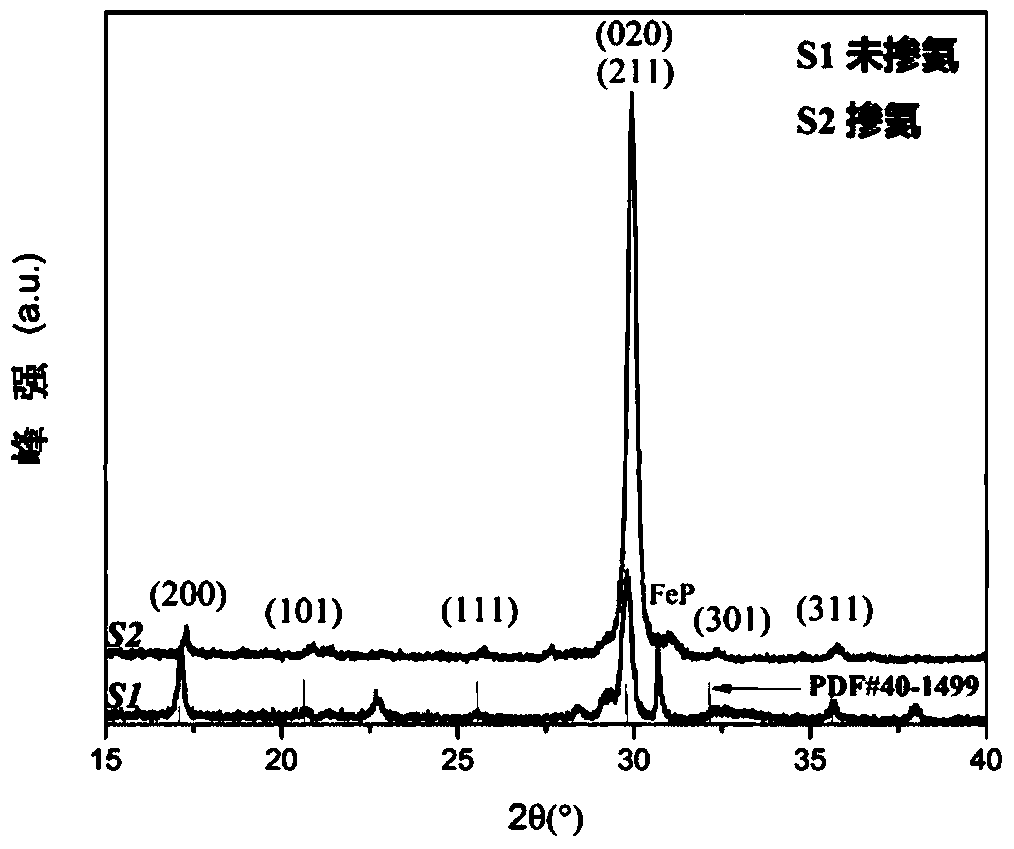

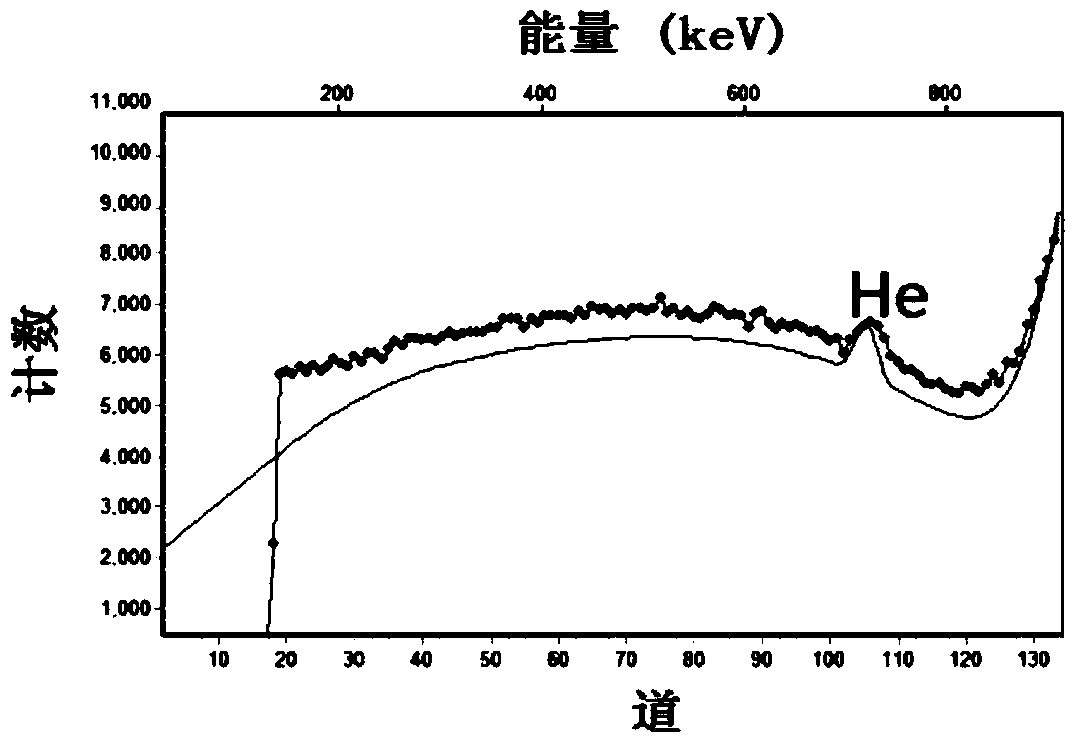

[0032] It is measured that the content of He atoms in the positive electrode material thin film is 8.2 at%, the discharge capacity o...

Embodiment 2

[0034] (1) Place the cleaned 316 stainless steel sheet in a magnetron sputtering vacuum chamber with a background vacuum pressure of 7.0×10 -4 Pa, under the sputtering power of 60W, carry out radio frequency magnetron sputtering coating, with a purity of not less than 99.95wt% ceramic LiFePO 4 The target is used as the sputtering source, and a mixed gas of Ar and He is introduced at the same time during sputtering, wherein the pressure of Ar is 1.0Pa, the gas pressure ratio of Ar and He is 10:4, and the sputtering deposition time is 40min;

[0035] (2) LiFePO obtained in step (1) 4 / He thin film cathode material was annealed in a high vacuum annealing furnace, the annealing temperature was 600°C, and the annealing pressure was 7.0×10 -4 Pa, annealed for 1.5 hours, after the annealing is completed, cool with the furnace and come out of the furnace.

[0036] The content of He atoms in the film prepared in this embodiment is 22.0 at%. and the helium-doped LiFePO 4 Cathode mat...

Embodiment 3

[0038] (1) Place the cleaned 316 stainless steel sheet in a magnetron sputtering vacuum chamber with a background vacuum pressure of 8.0×10 -4 Pa, under the sputtering power of 60W, carry out radio frequency magnetron sputtering coating, with a purity of not less than 99.95wt% ceramic LiFePO 4 The target is used as the sputtering source, and a mixed gas of Ar and He is introduced at the same time during sputtering, wherein the pressure of Ar is 2.0Pa, the gas pressure ratio of Ar and He is 10:2, and the sputtering deposition time is 20min;

[0039] (2) LiFePO obtained in step (1) 4 / He thin film cathode material is annealed in a high vacuum annealing furnace, the annealing temperature is 400°C, and the annealing pressure is 8.0×10 -4 Pa, annealed for 1.2 hours, after the annealing is completed, cool with the furnace and come out of the furnace.

[0040] It is measured that the content of He atoms in the positive electrode material thin film is 13.5 at%, the discharge capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com