Fuel cell system and control method thereof

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of inability to raise the overall temperature of the fuel cell stack, slow temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

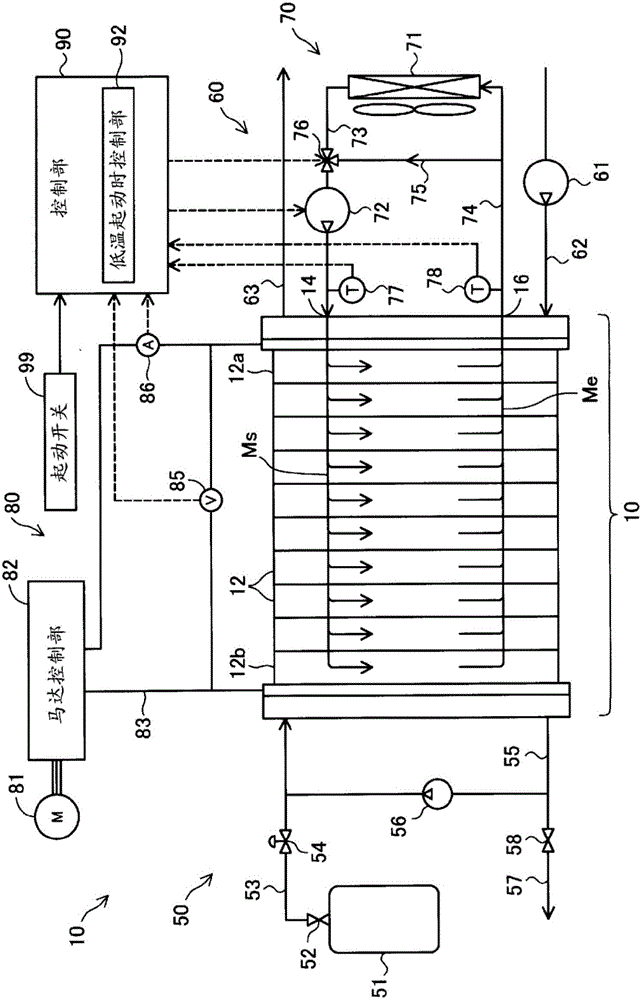

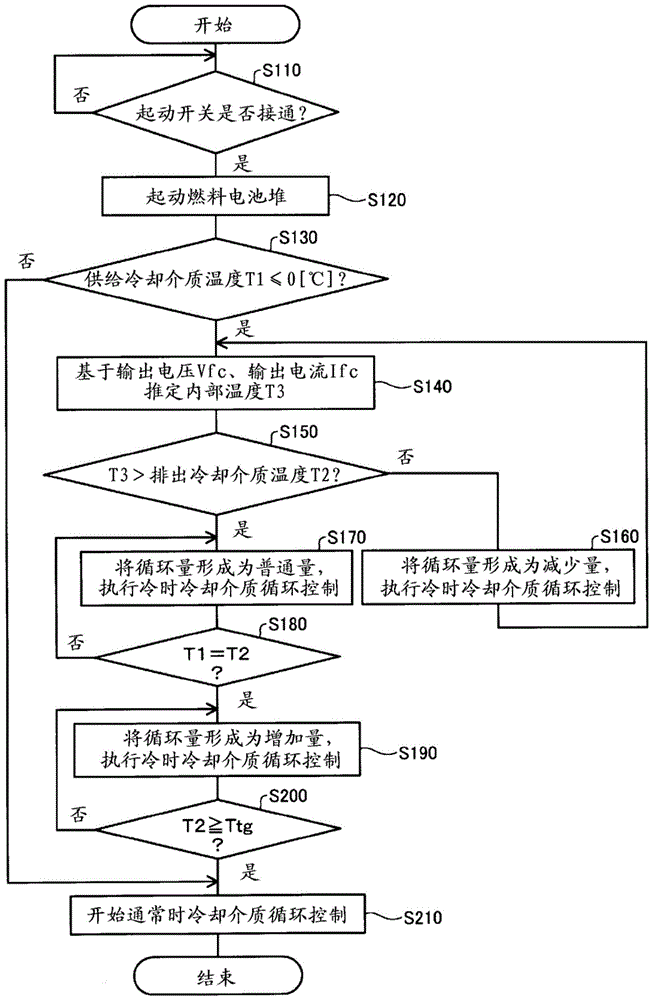

Method used

Image

Examples

Deformed example 1

[0053] In the above-described embodiment and its modification, the heat generation value of the fuel cell stack 10 is obtained based on the output voltage Vfc and the output current Ifc of the fuel cell stack 10, and the fuel cell stack 10 is estimated based on the heat generation value and the heat capacity of the fuel cell stack 10. The structure of the internal temperature T3, but not limited to this. For example, a temperature sensor may be used to obtain the temperature of a representative fuel cell unit (for example, a central unit in the stacking direction) constituting the fuel cell stack 10, and obtain the obtained temperature as an internal temperature. In addition, the temperature distribution of each fuel cell unit may be obtained experimentally in advance, and the temperature distribution of a representative fuel cell unit (for example, a unit in the center in the stacking direction) constituting the fuel cell stack 10 may be obtained using a temperature sensor. t...

Deformed example 2

[0055] In the above embodiment and its modifications, the fuel cell system mounted on a vehicle has been described as an example, but the present invention is not limited thereto and can be applied to various mobile bodies such as motorcycles, ships, airplanes, and robots. In addition, the present invention is not limited to a fuel cell system mounted on a mobile body, and may be applied to a stationary fuel cell system or a portable fuel cell system.

Deformed example 3

[0057] In the above-mentioned embodiment and its modifications, the solid polymer fuel cell is used in the fuel cell stack, but various fuel cells such as phosphoric acid fuel cells, molten carbonate fuel cells, and solid oxide fuel cells may also be used. The invention is applied to batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com