Three-plate motor iron-core progressive die

A three-plate, progressive die technology, used in the manufacture of stator/rotor bodies, metal processing equipment, stripping devices, etc., can solve the problems of unreasonable relative position of stable accuracy, shortening service life, etc., to ensure service life and correct position. , the effect of uniform gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

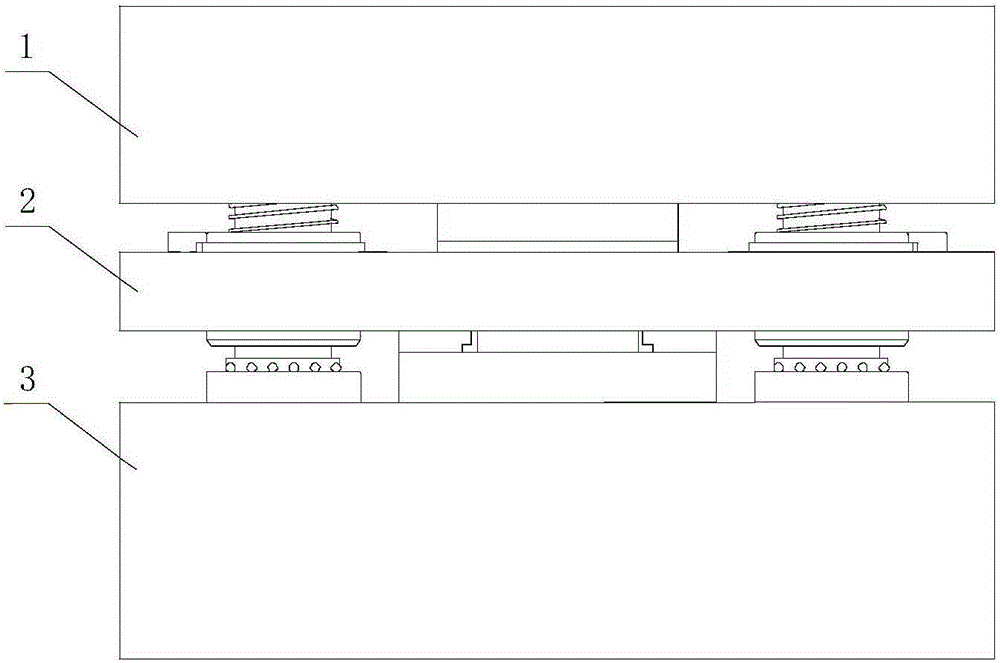

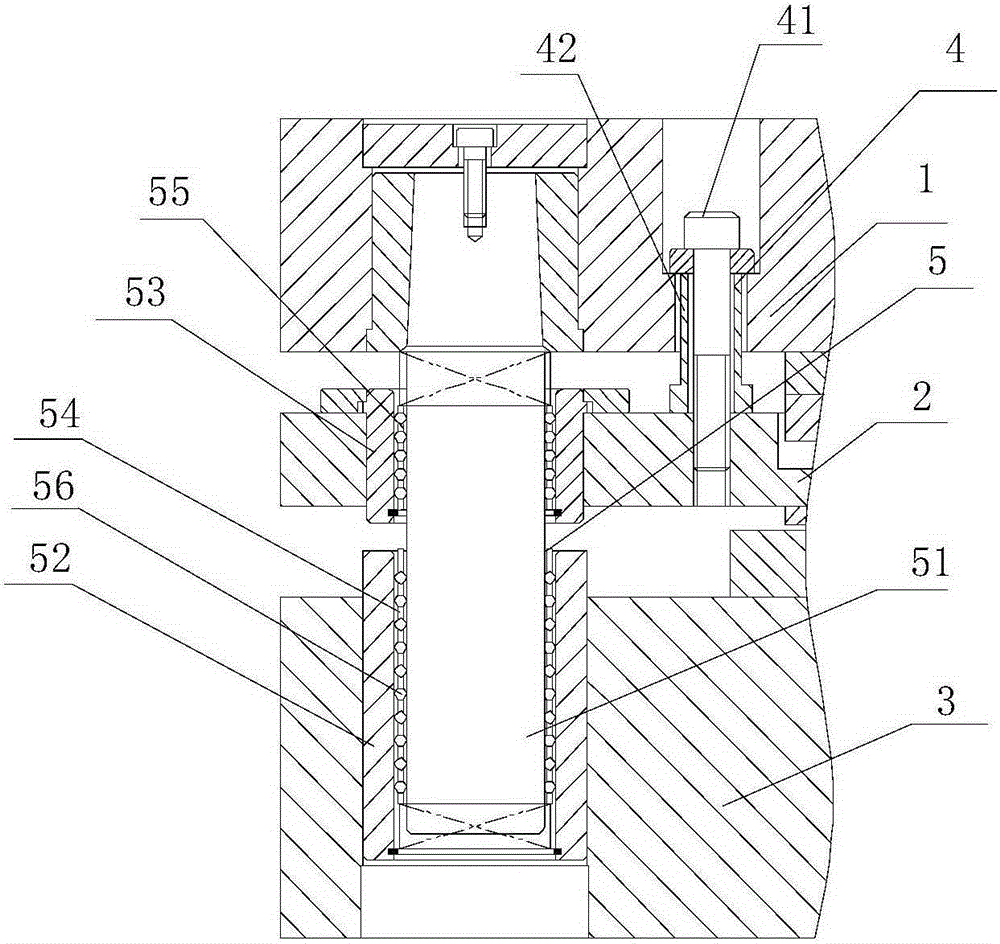

[0018] Embodiment 1 The three-plate motor iron core progressive die described in the present invention includes an upper die base 1, a stripping plate base 2 and a lower die base 3 matched with the upper die base, and the upper die base 1 is connected with the punching machine. The slider is affixed, the lower mold base 3 is fixed on the working table of the punch press, the stripper plate base 2 is fixedly connected with the upper mold base 1 through the fixing part 4, and the upper mold base 1 1. The stripper base 2 and the lower die base 3 are arranged in turn from top to bottom to form a three-plate structure, and the upper die base 1 is equipped with a guide device 5; the guide device 5 includes a guide Column 51, the first guide sleeve 52 installed on the lower mold base 3, the second guide sleeve 53 installed on the stripper seat, the first retaining ring 54 and the second retaining ring 55, the upper part of the guide post 51 It is fixedly connected with the upper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com