Right wallboard component for blueprint machine

A technology of printing machine and wallboard, which is applied in the directions of optics, instruments, printing equipment, etc., can solve the problems of reducing the processing accuracy of printing machine, difficult manual operation, large amount of drawings, etc., to achieve accurate size, ensure qualification, The effect of the correct position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

[0012] The ammonia-free printing machine has two wall panels, left and right. The left and right wall panels are installed on both sides of the chassis of the printing machine, providing an optimized size and shape for the machine, and a suitable proportion for human operation. Form a visually beautiful line shape.

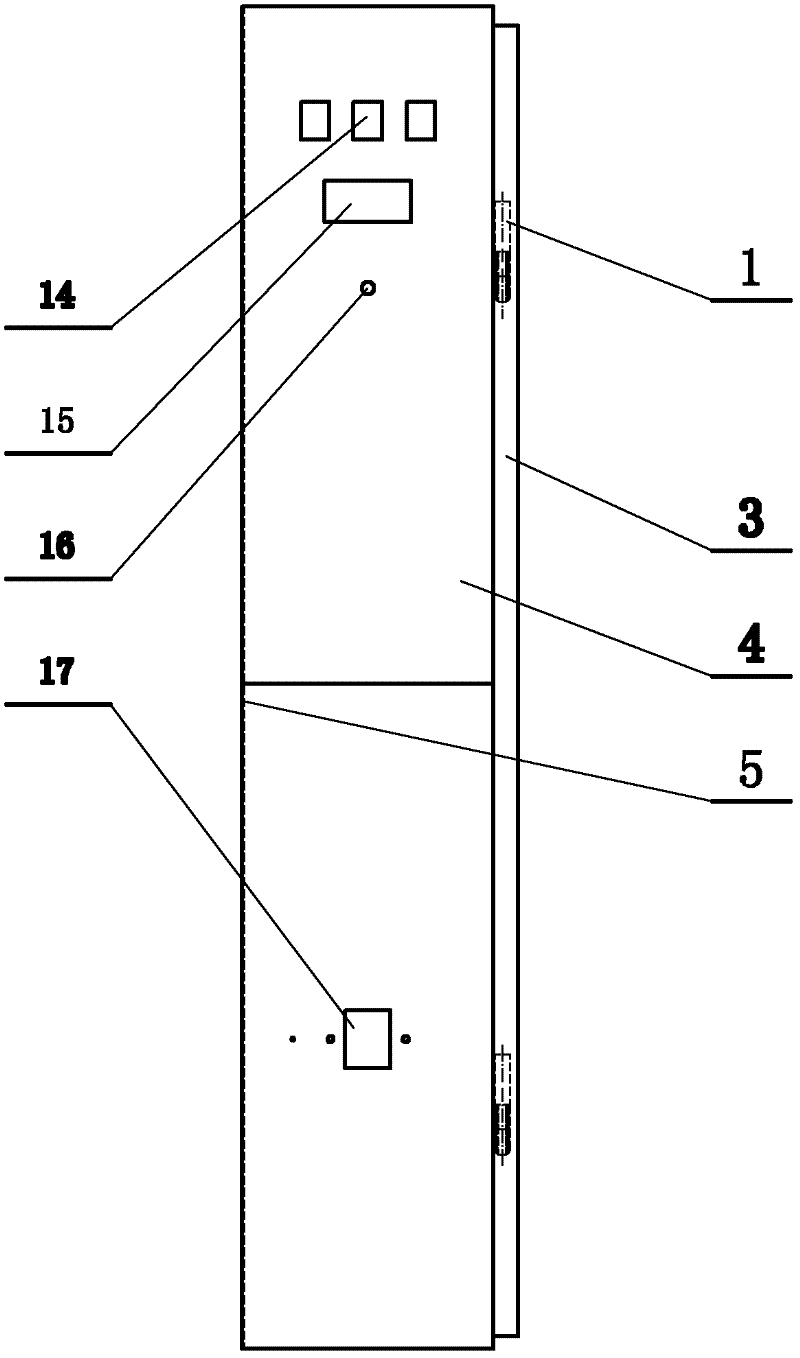

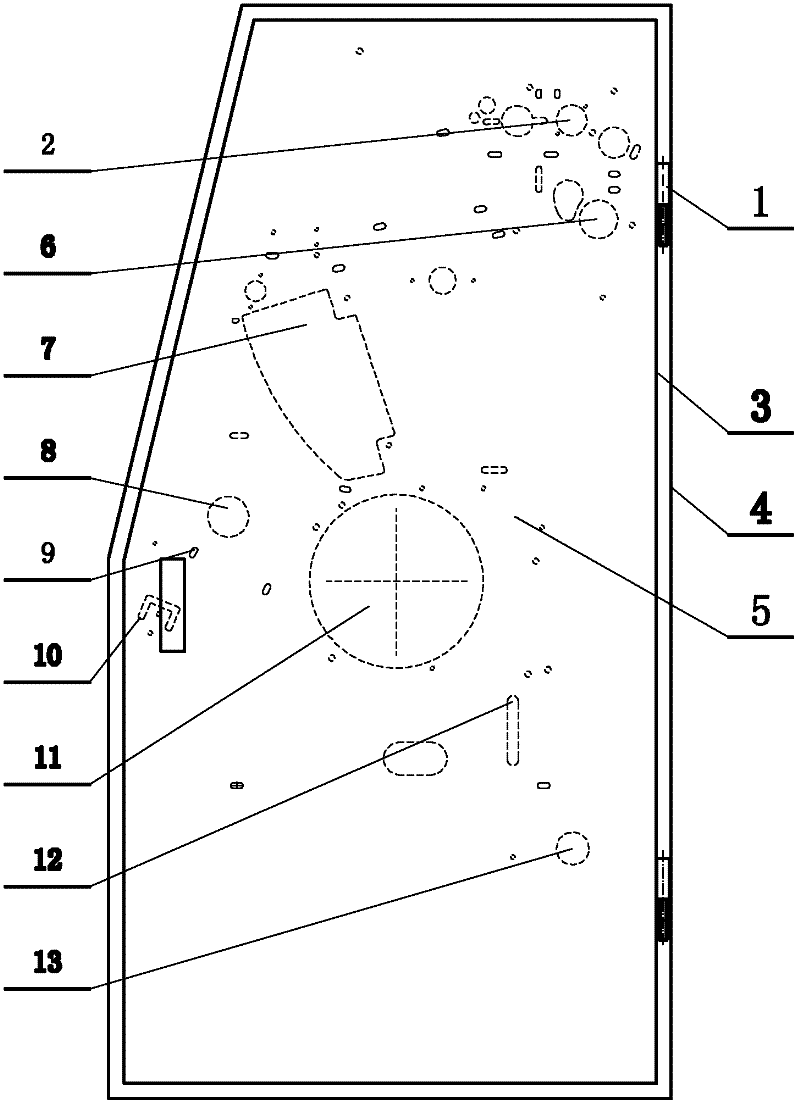

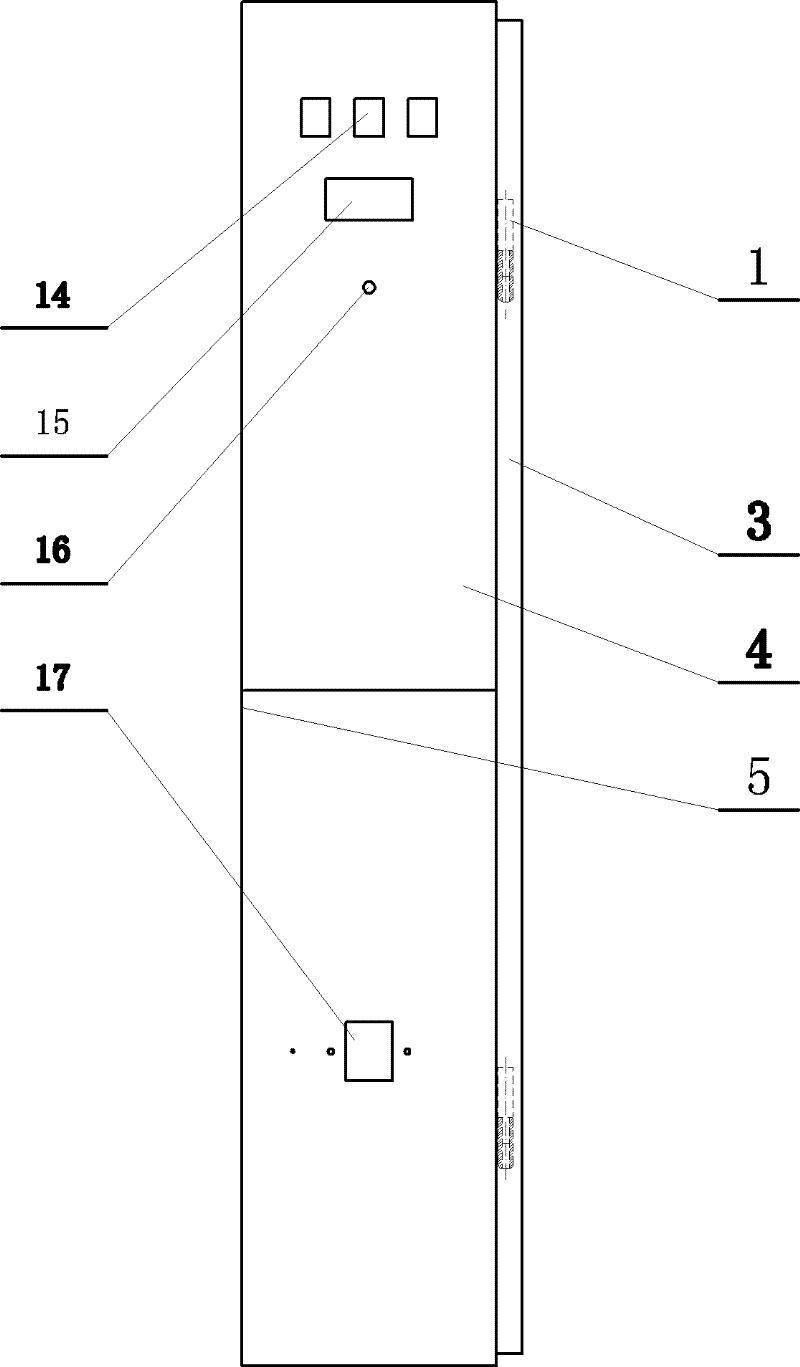

[0013] like figure 1 , shown in 2, wherein the right wall panel parts include: a safety protection door 3, an outer casing 4 and a right wall panel 5, and the outer casing 4 is connected end to end by a top surface, a first vertical surface, a bottom surface, a second vertical Face, oblique side form cylinder, and an end face of cylinder is closed by right wallboard 5, and safety protection door 3 is installed on the other end face of cylinder, is connected by hinge 1 between safety protection door 3 and outer casing 4.

[0014] The said right wall panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com