A honing tool device with the function of processing non-circular special-shaped holes

A technology of hole processing and round special-shaped, which is applied in the field of precision inner hole processing tools, can solve the problems of inability to process non-circular special-shaped inner holes, and achieve the effect of good processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

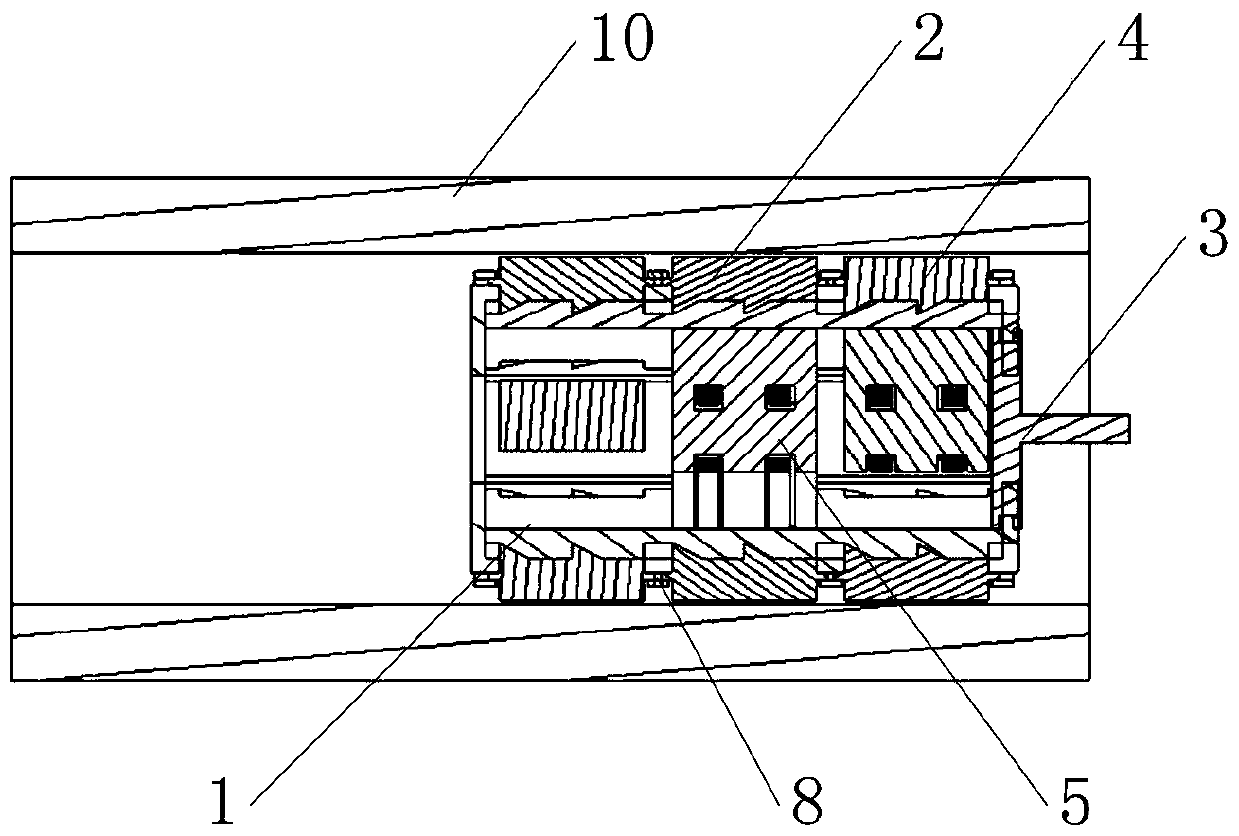

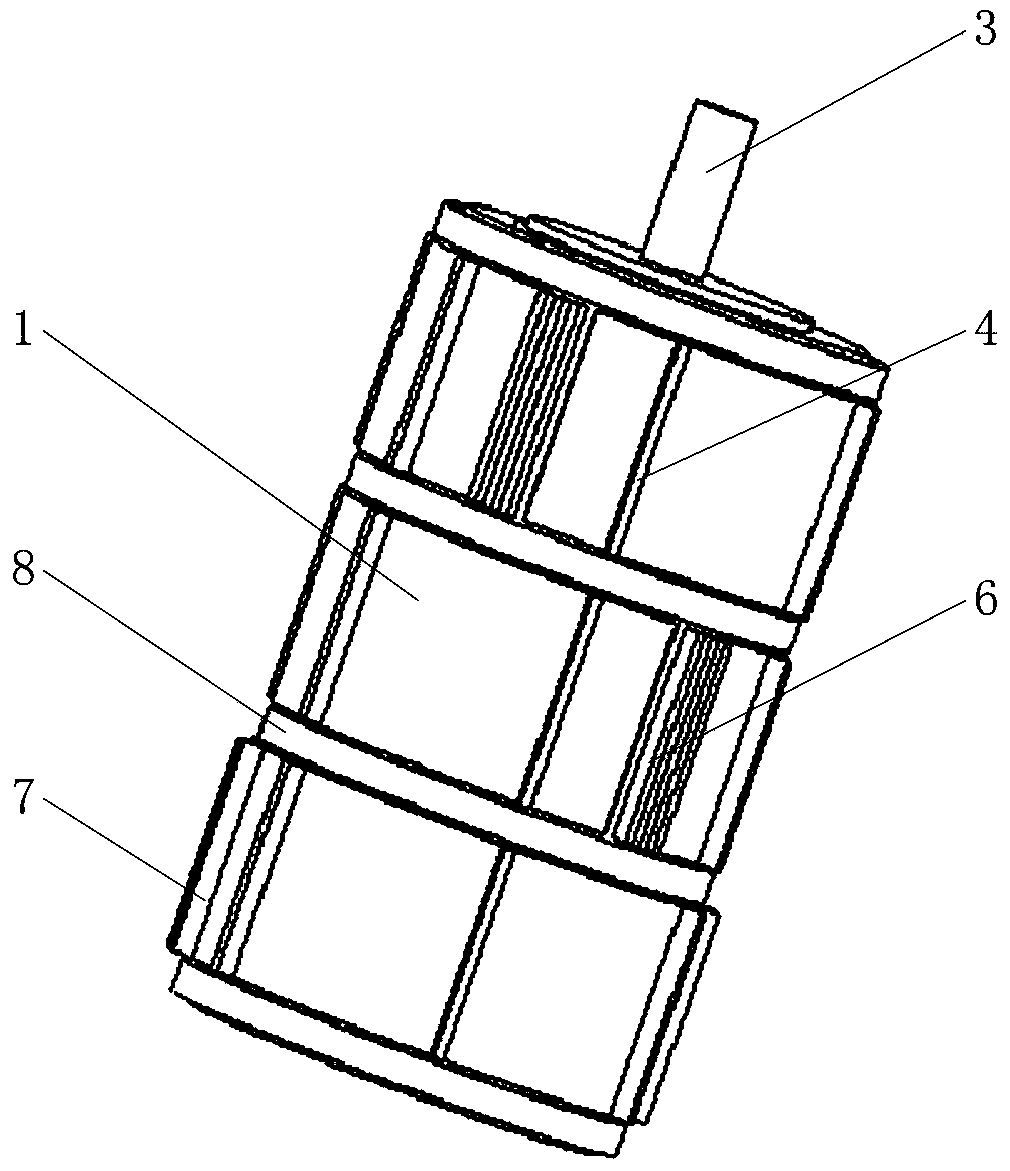

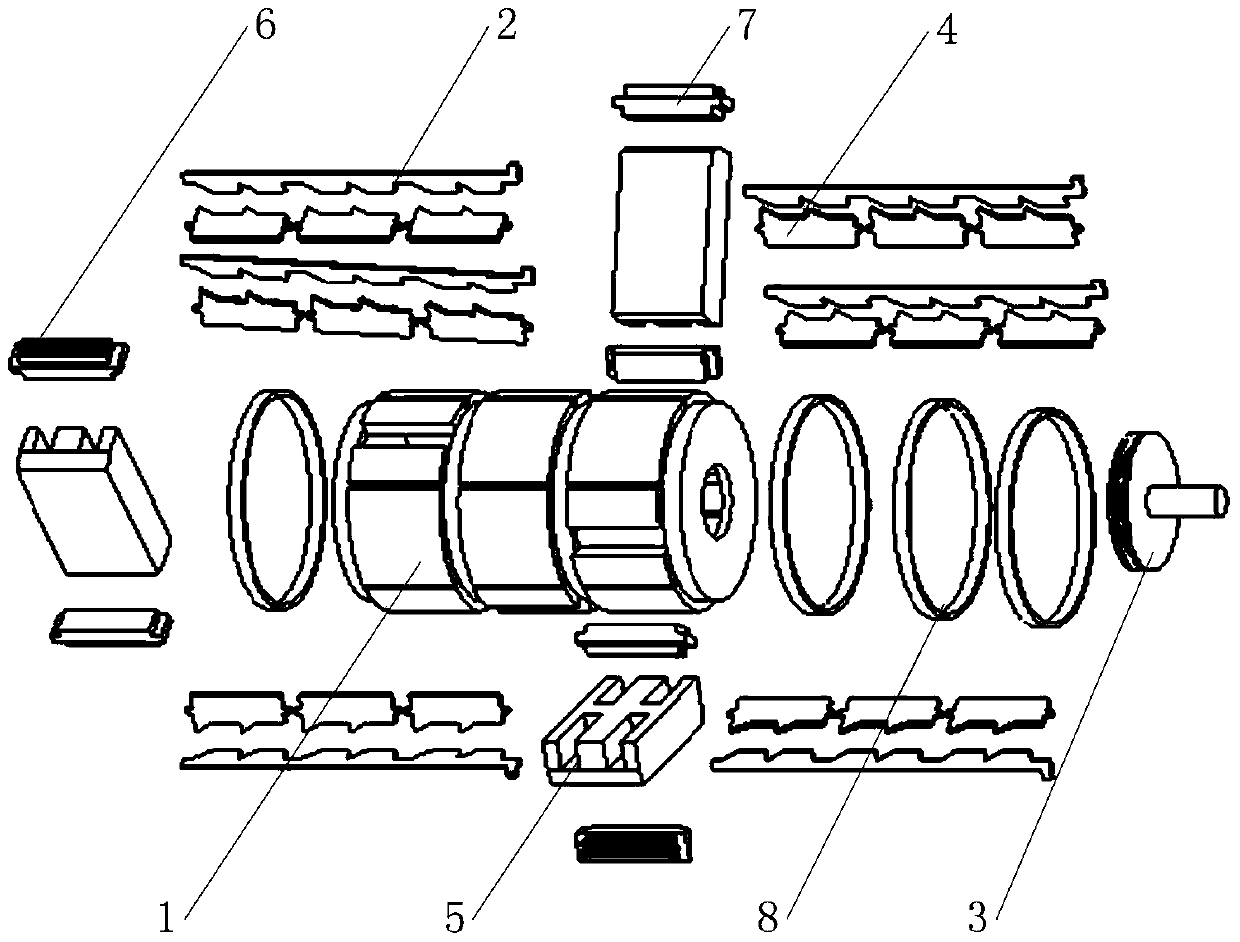

[0032] A honing tool device with the function of processing non-circular special-shaped holes, which can be processed in the inner hole 10, such as figure 1 and figure 2 As shown, this example includes: tool body 1, wedge-shaped cutter expansion assembly 2, axial feed assembly 3, main oilstone seat 4, actuator group 5, compensation oilstone seat 6 with compensation oilstone installed, support rod 7, retraction Knife spring coil 8. The wedge-shaped tool expansion assembly 2 is installed on the inner wall of the tool body 1, and the tail is connected with the axial feed assembly 3. The bottom of the main oil stone seat 4 is connected with the wedge-shaped knife-expanding assembly 2, and the two ends are respectively pressed by the knife-retracting spring ring 8. The compensating oil stone seat 6, the actuator group 5, the support rod 7, and the knife retracting spring coil 8 form a compensating mechanism. The bottom of the compensating oilstone seat 6 and the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com