Automatic paper cutter

A paper cutter and automatic technology, applied in metal processing, household appliances, etc., can solve the problems of high cost, large space occupation, and low efficiency, and achieve the effects of simple structure, prevention of cross infection, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

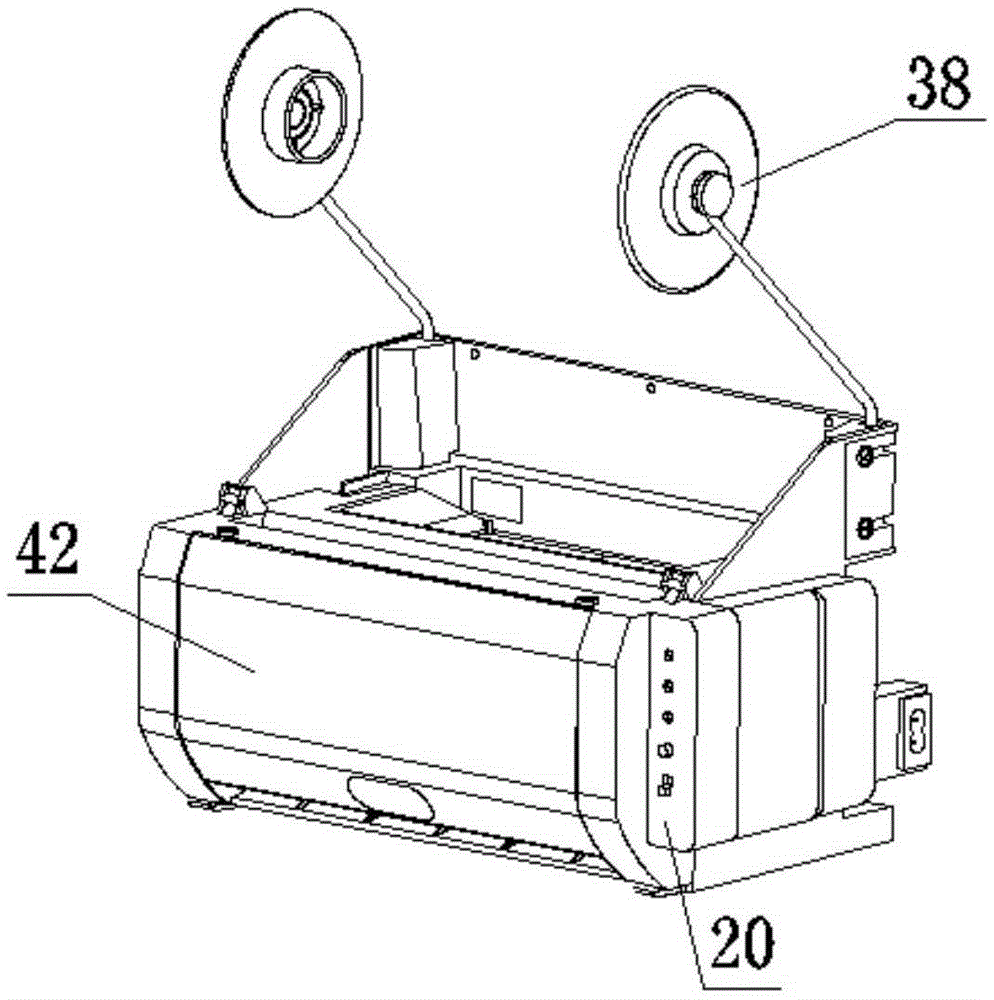

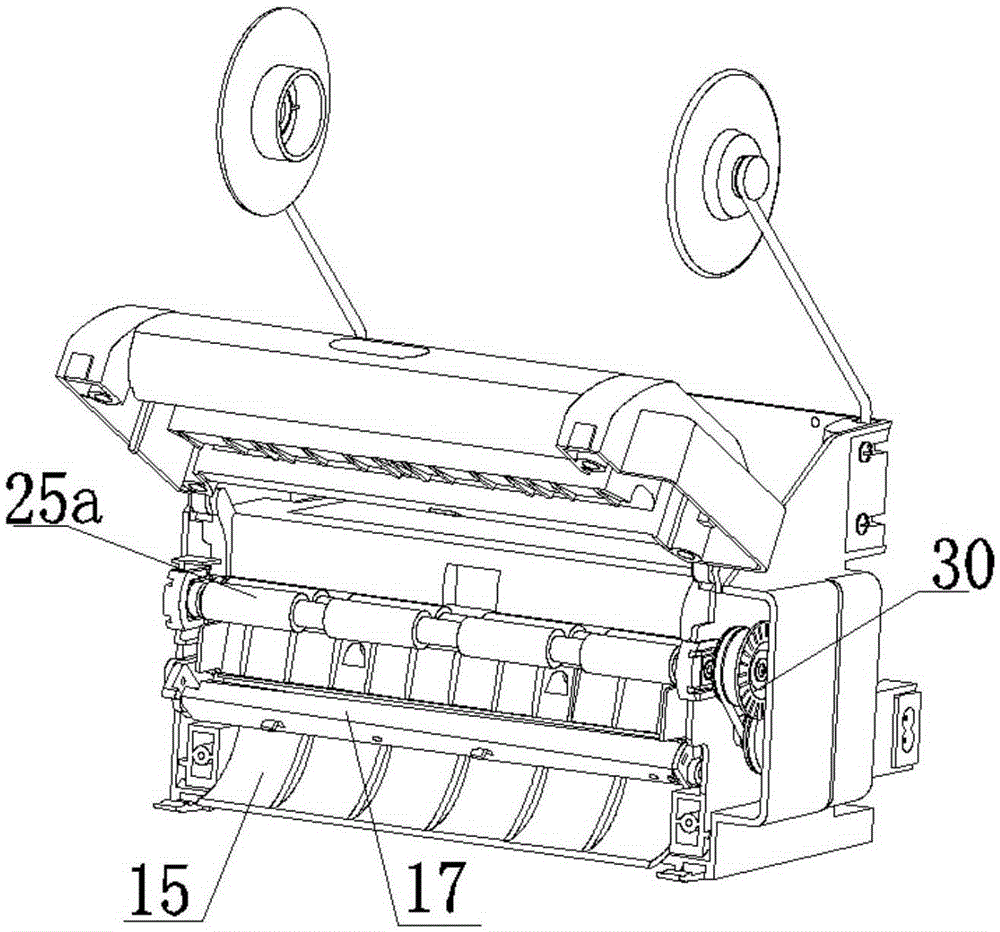

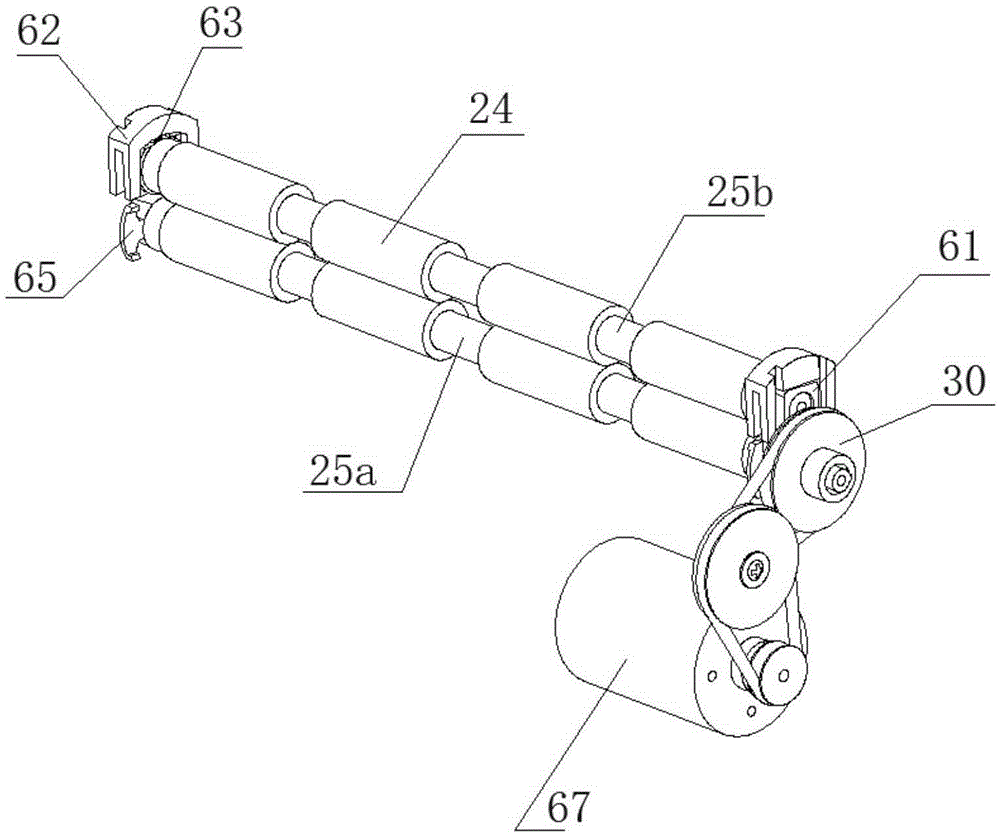

[0022] see Figure 1-Figure 9 , the automatic paper cutter of the present invention includes a housing, a paper clamping support 38, a paper feeding mechanism, a paper cutting mechanism and a plurality of circuit boards.

[0023] Specifically, the casing is a box. Its front is embedded with an accommodating space, and the accommodating space is provided with a loam cake 42, and this loam cake 42 is movably connected with the shell through the loam cake bracket, so that loam cake 42 can rotate and open and close around the loam cake bracket. Various circuit boards are built in the accommodation space. The upper cover 42 is provided with a sensing window 44 . The back of the housing is embedded with a battery box 70, and batteries are stored in the battery box 70 for supplying power to various electrical components. A circuit board C is provided on one side of the casing, and a plurality of buttons 21 are provided on the circuit board C.

[0024] The paper clamping bracket 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap