Cylinder floating double active roller feeding mechanism

A dual-active, floating technology, which is applied in the manufacture of flat surface processing machines, wood processing appliances, workpiece feeding devices, etc., can solve the problems of long time consumption, low processing accuracy, increased raw material waste, etc., to save production. Cost, good feeding stability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

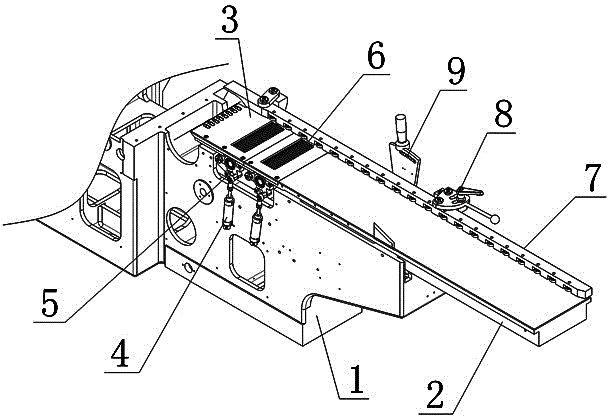

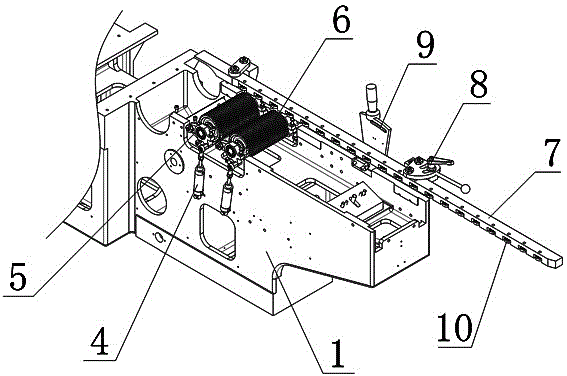

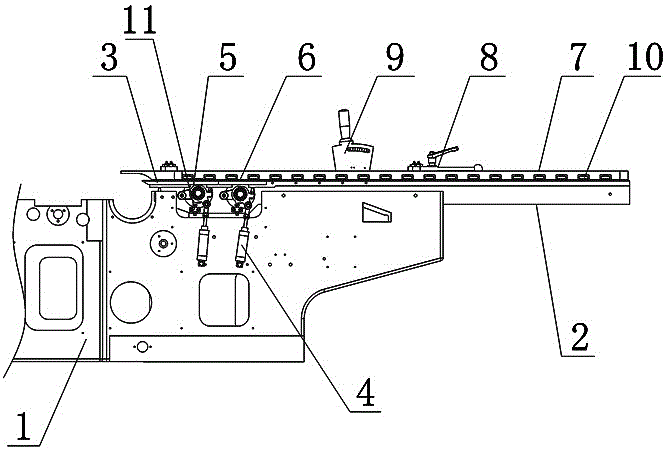

[0024] Such as figure 1 , figure 2 and image 3 As shown, the cylinder floating double active roller feeding mechanism includes body 1, movable table 2, cylinder 4, pendulum frame 5 and feeding roller 6, movable table 2 is installed on the top of body 1, and the upper part of movable table 2 is fixed A movable workbench mouth plate 3 is installed, two cylinders 4 are respectively arranged on the two side walls of the body 1, the tail of the cylinder 4 is hingedly installed on the side wall of the body 1, and each cylinder 4 is hinged with a pendulum 5 respectively, as Figure 5 As shown, the swing frame 5 includes a swing frame body 51, a cylinder connecting plate 53 and a hinge plate 54, the center of the swing frame body 51 is provided with a bearing hole 52, one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com