High-speed high-precision 3D printer

A 3D printer, high-precision technology, applied in the field of 3D printing, can solve problems such as poor transmission stability, insufficient rigidity, reduced surface smoothness, and influence on printing speed, so as to facilitate printing accuracy and printing speed, reduce shaking and angle inclination , temperature control, soft and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

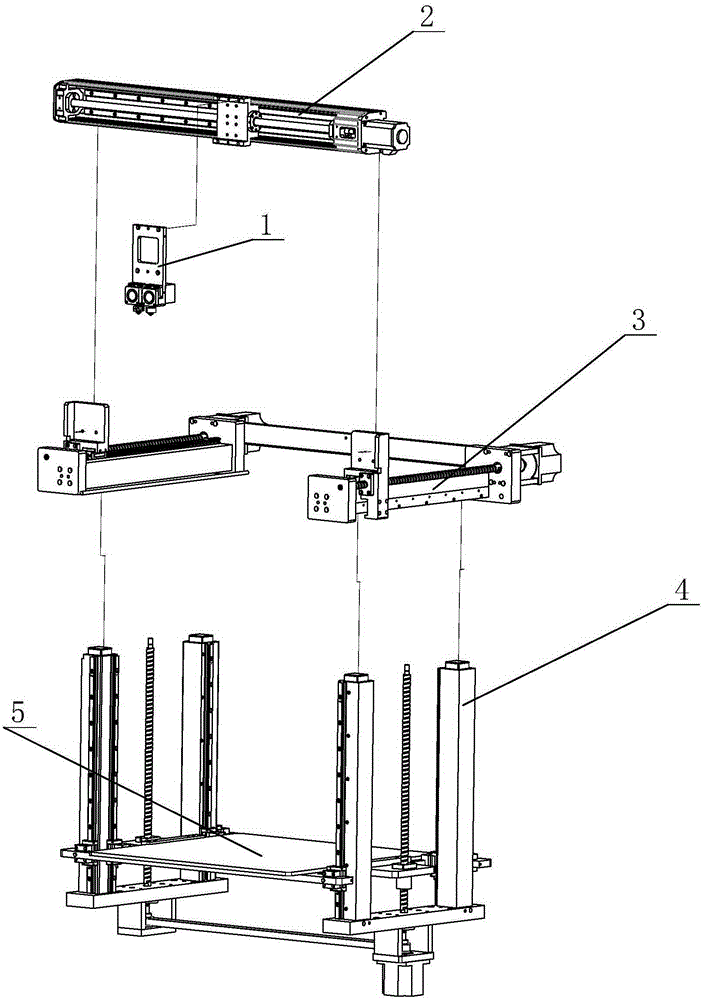

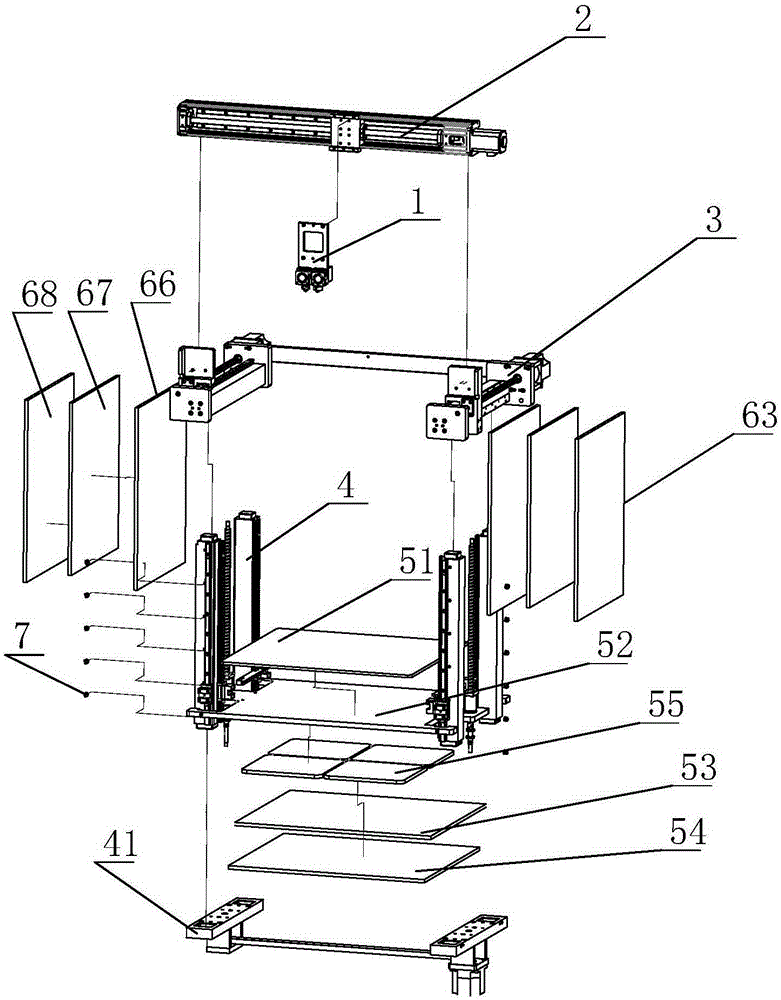

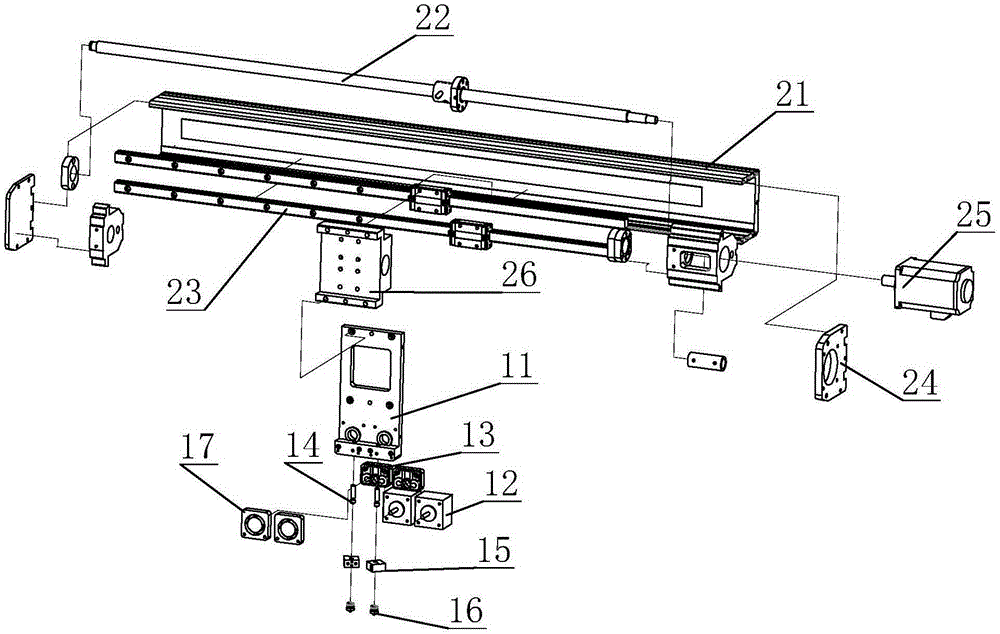

[0052] Embodiment 1: The present invention is a high-speed and high-precision 3D printer. The main structure includes a three-dimensional motion frame, an extrusion mechanism 1, a platform mechanism 5, and a machine shell 6. The machine shell 6 combines the three-dimensional motion frame, extrusion Exit mechanism 1, platform mechanism 5 are covered inside, and described machine housing 6 comprises frame 61 and top board 62 fixed on frame 61, side board 63, door board 64 and corner wheel 65, and described top board 62, door board 64, outer side The sealing plates 68 are all sheet metal parts, and the top plate 62, the side plates 63, and the door panels 64 jointly enclose a closed rectangular cabinet shell, and the door panels 64 are provided with a transparent observation area. The side plate 63 includes an inner splint 66 , a heat insulating cotton interlayer 67 and an outer sealing plate 68 sequentially connected from inside to outside. The three-dimensional motion frame inc...

Embodiment 2

[0054] Embodiment 2: The present invention is a high-speed and high-precision 3D printer. The main structure includes a three-dimensional motion frame, an extrusion mechanism 1, a platform mechanism 5, and a machine shell 6. The machine shell 6 combines the three-dimensional motion frame, extrusion The output mechanism 1 and the platform mechanism 5 are covered inside, the machine casing 6 is provided with an air filter, and the three-dimensional motion frame includes an X-axis module 2, a Y-axis module 3 and a Z-axis module 4, so The Z-axis module 4 includes two symmetrical and horizontally arranged fixing plates 41, on which the Z-axis ball screw 42 is vertically rotated along the Z-axis, and the two Z-axis ball screws 42 Driven by 86 stepper motors, and the speed is synchronized. Both ends of the fixed plate 41 are vertically provided with a Z-axis column 43 along the Z-axis direction, and the Z-axis column 43 is connected with the machine casing 6 by a plurality of positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com