Air-pressure type service braking system having hill-starting assisting function

An auxiliary function and service braking technology, applied in the directions of brakes, brake transmission devices, control devices, etc., can solve the problems of long response time of hill start assist, influence of brake pipeline, complex system structure, etc. Improve the control effect, use safety, and improve the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

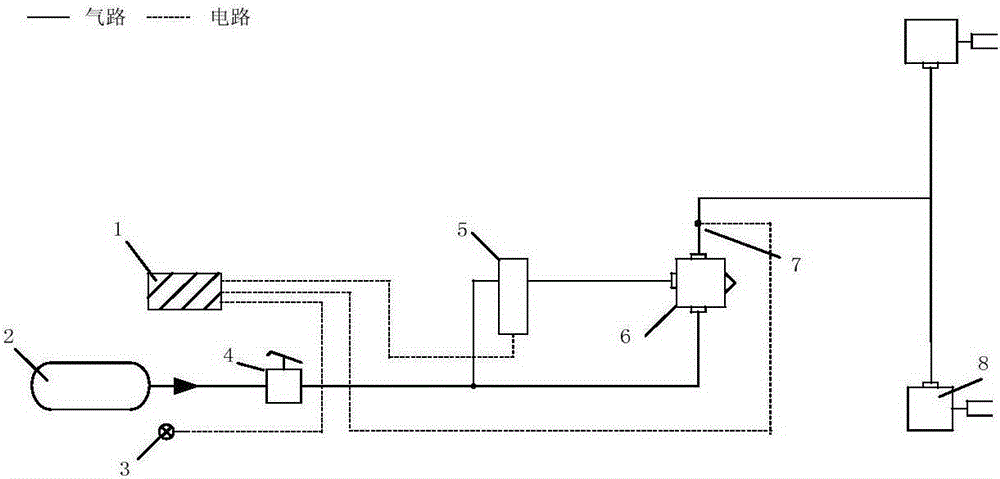

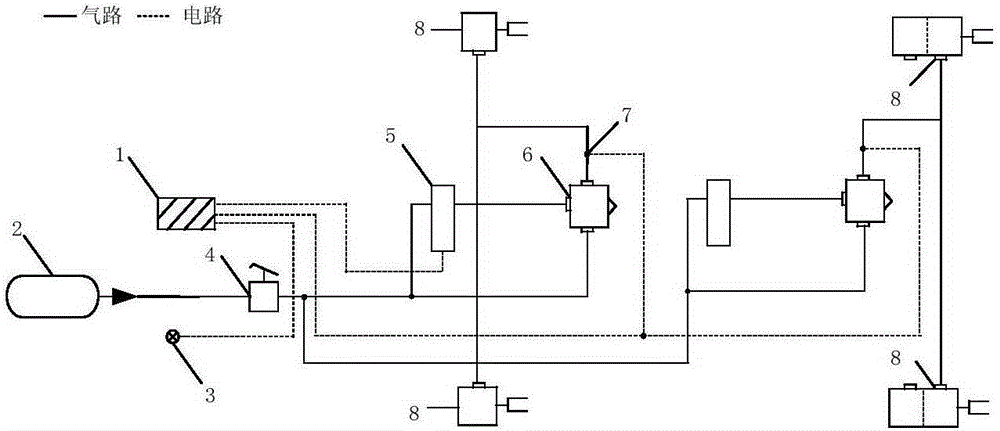

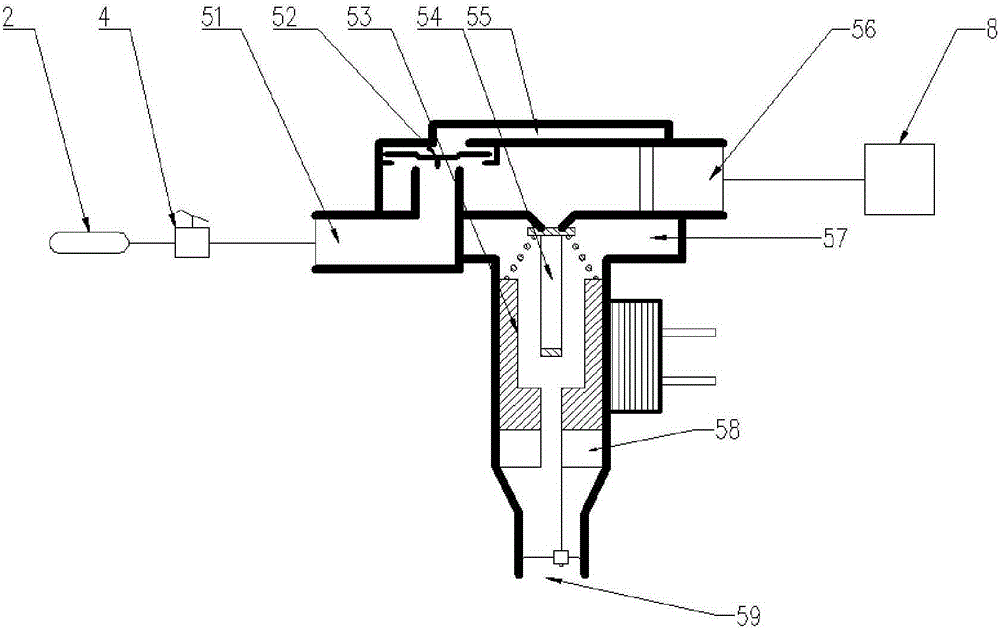

[0022] Such as figure 1 As shown, the present invention has the pneumatic service brake system of hill start assisting function, comprises the air storage tank 2, foot valve 4 and brake air chamber 8 that are connected in series by air circuit, in described foot valve 4 and brake air A relay valve 6 is connected in series between the chambers 8, and a pneumatic control solenoid valve 5 is also included. One end of the pneumatic control solenoid valve 5 is connected to the air path of the relay valve 6, and the other end is connected to the outlet gas path of the foot valve 4. .

[0023] It also includes an electronic controller 1 and an air pressure sensor 7 connected with it, the air pressure sensor 7 is placed on the air path between the relay valve 6 and the brake chamber 8, and the electronic controller 1 is also connected with the pneumatic control electromagnetic Valve 5 is electrically connected.

[0024] The pneumatic service brake system with slope start assist func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com