Jacking device for replacing saddle arm of rotating bearing of continuous casting rotating table and construction method of jacking device

A technology of jacking device and slewing bearing, which is applied in the direction of lifting device, etc., to achieve the effect of reducing the risk of production shutdown and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the bearing replacement of the continuous casting rotary table with a weight of 224 tons and a bearing diameter of 4325mm as an example, as follows:

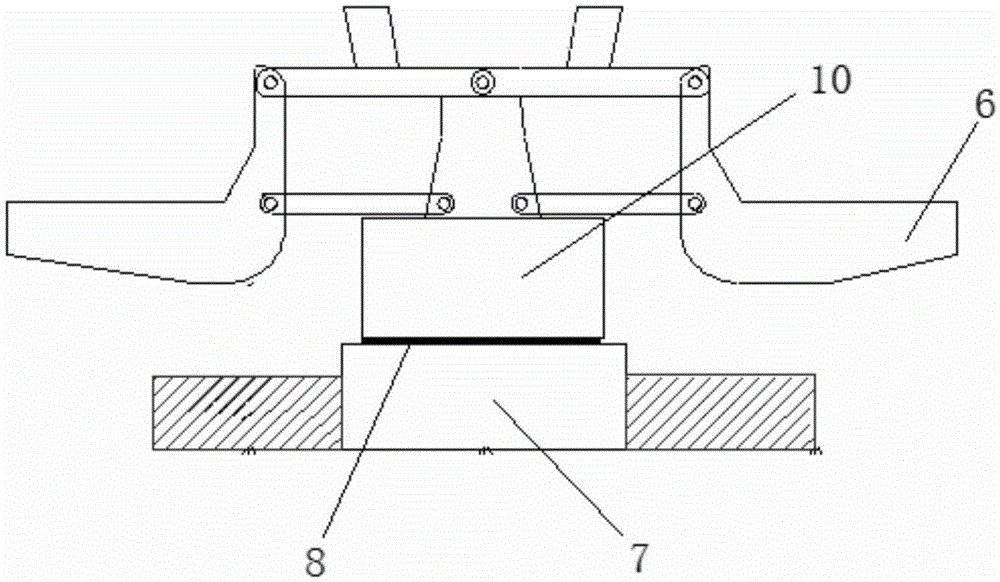

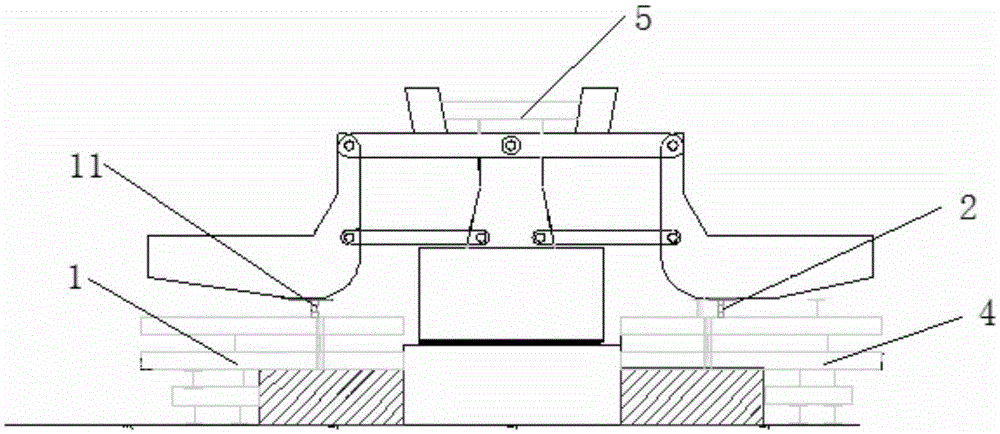

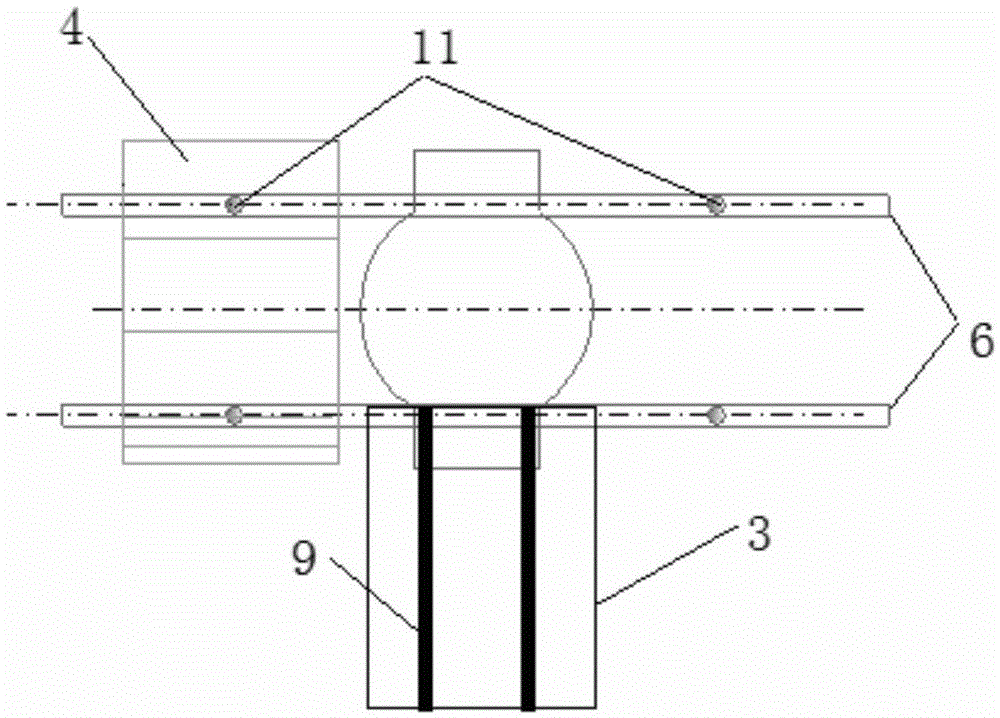

[0031] Such as Figure 1~3 As shown, a saddle arm jacking device for replacing the slewing bearing of a continuous casting turret includes a saddle arm support device 1 , a hydraulic jacking device 2 , and a bearing lateral movement support 3 .

[0032] The saddle arm supporting device 1 includes a steel structure load-bearing support 4 under the saddle arm 6 of the turntable and a rigid reinforcement member 5 inside the turntable. The steel structure load-bearing support 4 is superimposed directly below the saddle arm 6 using 400H-shaped steel wells. In addition, there is a gap for placing a hydraulic jack 11 between the steel structure load-bearing support 4 and the saddle arm 6, and the internal rigid reinforcement 5 of the turntable adopts 4 seamless steel pipes of D273*12, which are welded to the top beam of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com