Lifting mechanism of mass center and eccentricity conversion test equipment

A lifting mechanism, conversion testing technology, applied in the direction of lifting device, electromechanical device, control mechanical energy, etc., can solve the problems of equipment not working normally, unable to realize mechanism lifting, etc., and achieve the effect of convenient maintenance and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

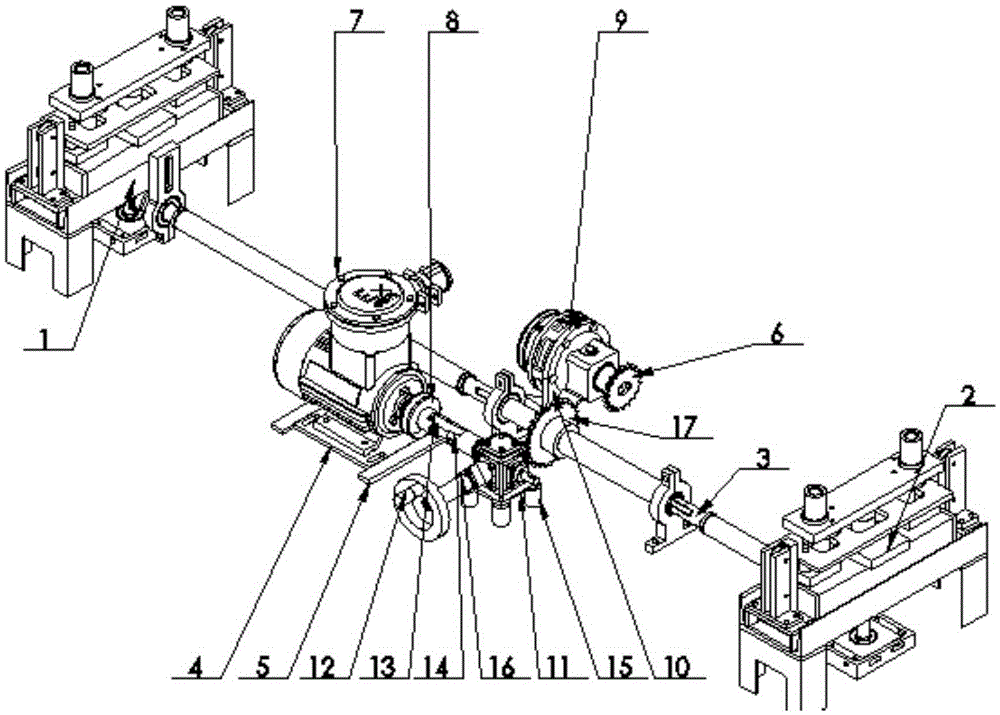

[0013] Such as figure 1 The equipment lifting mechanism shown includes a mounting plate 4, an explosion-proof motor 7 is arranged on the top of the mounting plate 4, a first pulley 8 is connected to the right side of the explosion-proof motor 7, and a connecting shaft rod 13 is arranged on the right side of the first pulley 8, and the connecting shaft rod The right side of 13 is provided with a shaft coupling 14, the right side of the shaft coupling 14 is connected with a steering mechanism 11, the front end of the steering mechanism 11 is connected with a connecting rod 16, the front end of the connecting rod 16 is connected with a hand wheel 12, and the lower part of the steering mechanism 11 is provided with a plurality of Support column 15; Explosion-proof motor 7 rear side is provided with transmission shaft 3, and the middle position of transmission shaft 3 is provided with first gear 17, and transmission shaft 3 left and right sides are respectively provided with first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com