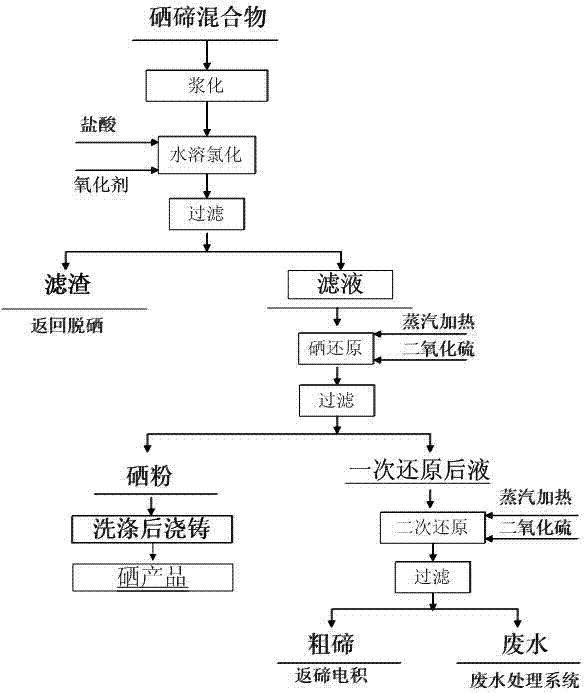

A method for separating and purifying selenium and tellurium from a mixture of selenium and tellurium

A mixture, selenium-tellurium technology, applied in the field of tellurium, separation and purification of selenium, can solve the problems of difficult separation of selenium-tellurium mixture, low extraction rate of selenium-tellurium and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 120Kg wet weight of selenium-tellurium mixture, which contains 35% water, 28.304% selenium, and 22.94% tellurium. After slurrying, add 150L hydrochloric acid, and add oxidant for water-soluble chlorination (the amount of oxidant added is until the slurry There are no visible solids in the medium, the oxidizing agent can be sodium chlorate), and the liquid-solid ratio is 3:1. After two staged reductions of sulfur dioxide (the first reduction steam is heated to 90°C, the second reduction steam is heated to 90°C, both using liquid sulfur dioxide), the output of selenium is 21.5kg, tellurium is 17.8kg, and the purity of selenium and tellurium is respectively 99% , tellurium 95%, the yield of selenium is 96.41%, the yield of tellurium is 94.51%.

Embodiment 2

[0028] 120Kg wet weight of selenium-tellurium mixture, which contains 35% water, 28.304% selenium, and 22.94% tellurium. After slurrying, add 140L hydrochloric acid, and add oxidant for water-soluble chlorination (the amount of oxidant added is until the slurry There are no visible solids in the medium, the oxidizing agent can be sodium chlorate), and the liquid-solid ratio is 3:1. After two staged reductions of sulfur dioxide (the first reduction steam is heated to 80°C, and the second reduction steam is heated to 90°C, both using liquid sulfur dioxide), the output of selenium is 20.4kg, tellurium is 16.8kg, and the purity of selenium and tellurium is 97% respectively. , tellurium 94%, the yield of selenium is 94.31%, the yield of tellurium is 92.64%.

Embodiment 3

[0030] 120Kg wet weight of selenium-tellurium mixture, which contains 35% water, 28.304% selenium, and 22.94% tellurium. After slurrying, add 160L hydrochloric acid, and add oxidant to carry out water-soluble chlorination (the amount of oxidant added is until the slurry There are no visible solids in the medium, the oxidizing agent can be sodium chlorate), and the liquid-solid ratio is 3:1. After two staged reductions of sulfur dioxide (the first reduction steam is heated to 80°C, and the second reduction steam is heated to 80°C, both using liquid sulfur dioxide), the output of selenium is 20.9kg, tellurium is 16.5kg, and the purity of selenium and tellurium is respectively 99%. , tellurium 94%, the yield of selenium is 94.53%, the yield of tellurium is 94.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com