A moisture-resistant phenolic molding compound

A phenolic molding compound, moisture resistance technology, used in the field of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

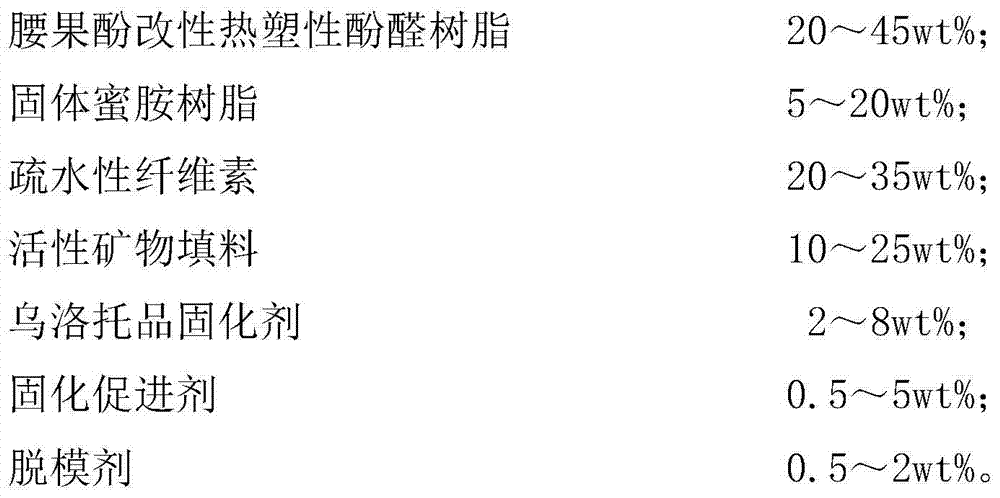

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0018] The manufacturing method of the molding material of the present invention can adopt the traditional twin-roller kneading method, and also can adopt the screw extrusion method.

[0019] Before kneading or extrusion, resin binders including cardanol modified thermoplastic phenolic resin and melamine resin, urotropine curing agent and curing accelerator are superfinely pulverized in advance, and the fineness reaches more than 200 mesh, and then the The above mixture is uniformly mixed with other raw materials, heated and kneaded or extruded, and finally granulated to obtain the desired product.

[0020] Below just illustrate the present invention:

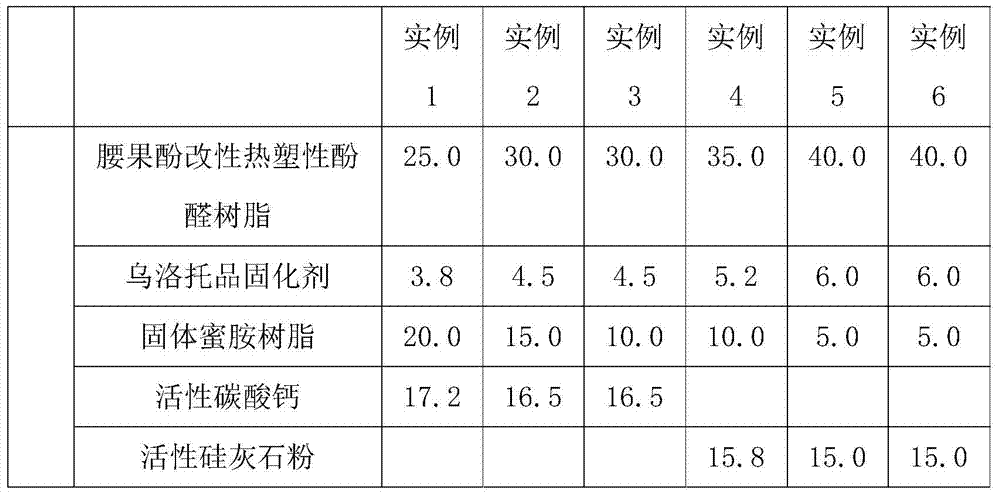

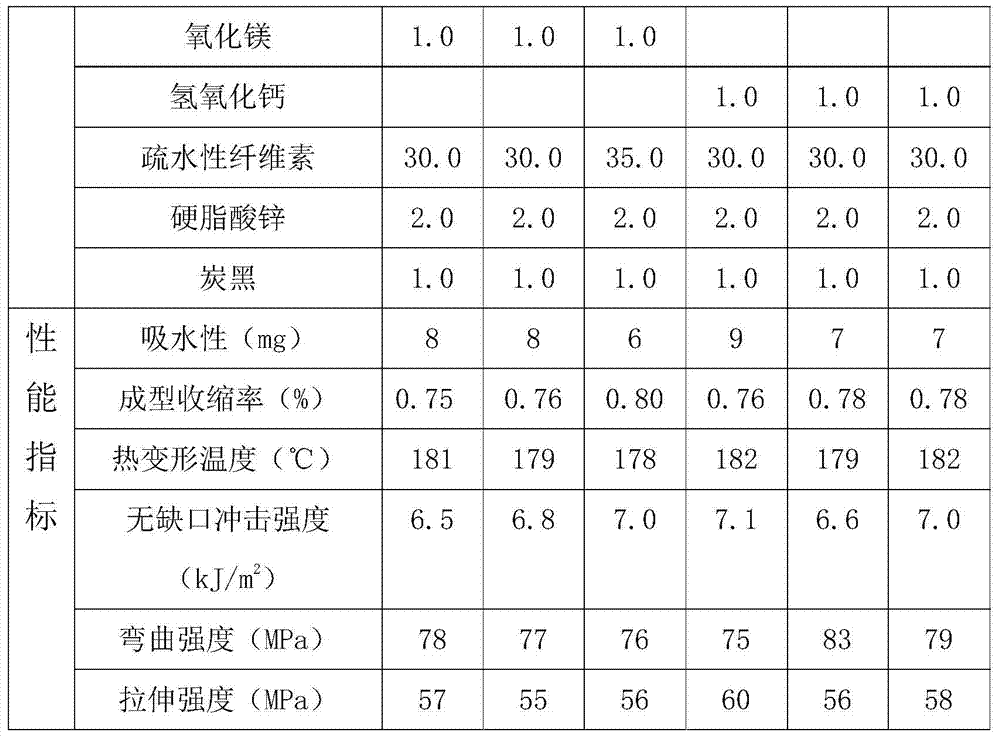

[0021] The formulation materials shown in Table 1 are pulverized, mixed and kneaded or extruded according to the aforementioned m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com