Dehydrated antirust oil composition and application thereof

A composition and technology for anti-rust oil, applied in the directions of lubricating compositions, petroleum industry, additives, etc., can solve the problems of conflict between the anti-rust performance and dehydration performance of dehydrated anti-rust oil, and achieve good technical effects and good anti-rust performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

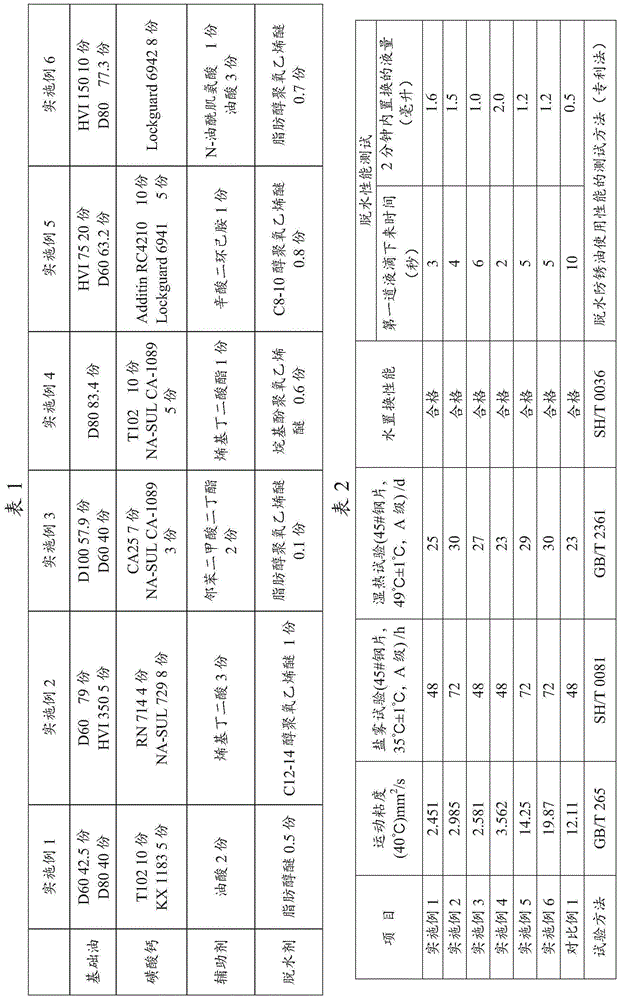

[0028] According to the parts by weight in Table 1, add the base oil into the blending kettle, heat and stir at 40-50 °C, then add oil-soluble calcium sulfonate rust inhibitor, auxiliary agent and dehydrating agent in turn, and stir at a constant temperature of 35-45 °C for 1 ~2 hours, through 10um bag filtration to obtain the dehydrated antirust oil composition.

Embodiment 1

[0032] It can be seen from Table 2 that the comprehensive properties of [Examples 1 to 6] provided by the present invention are better than those of [Comparative Example 1].

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com