Anti-pull high damping rubber shock-isolation bearing

A damping rubber and vibration-isolating bearing technology is applied in the field of vibration-absorbing and isolating bearing devices, and the anti-pulling requirements are in the field of vibration-isolating bearings. Clear effect of shock absorption and isolation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

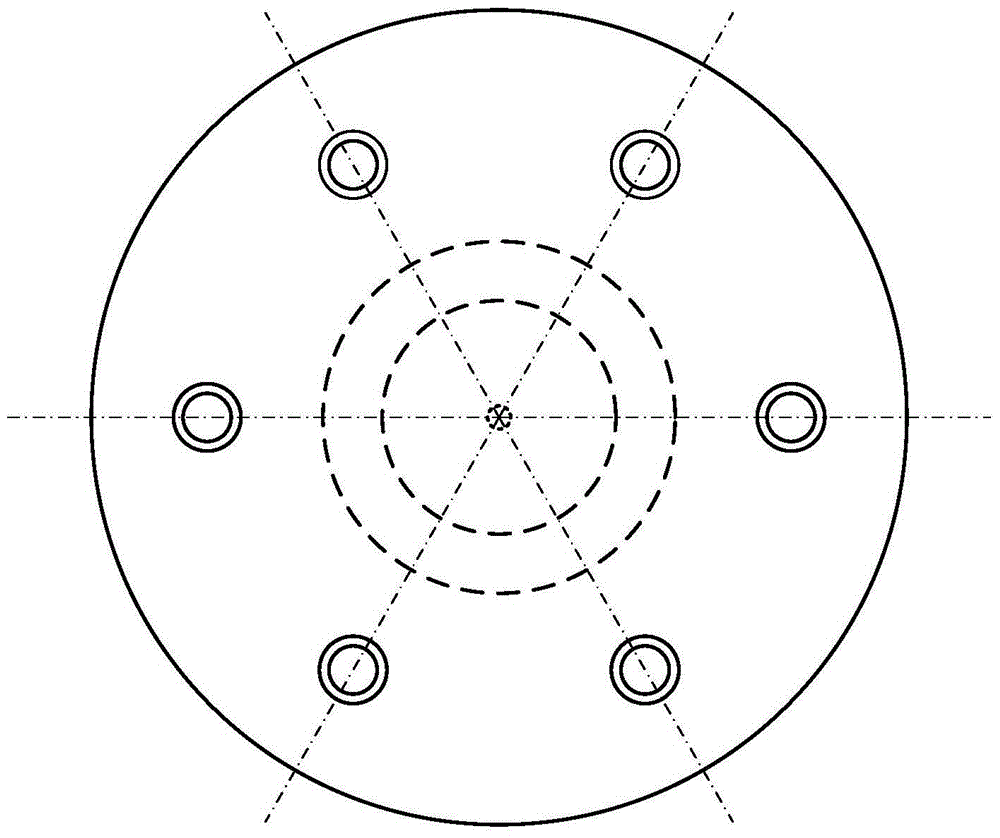

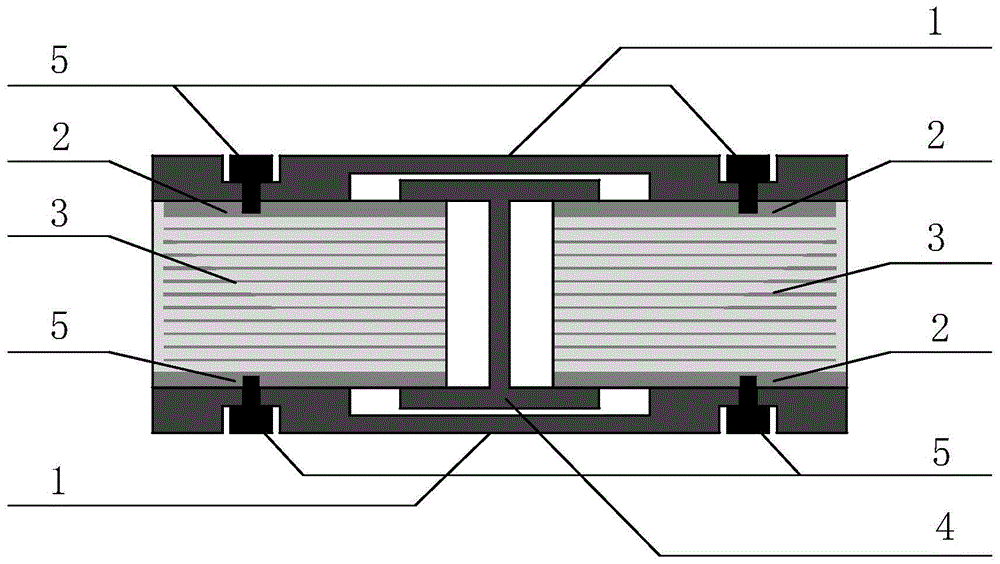

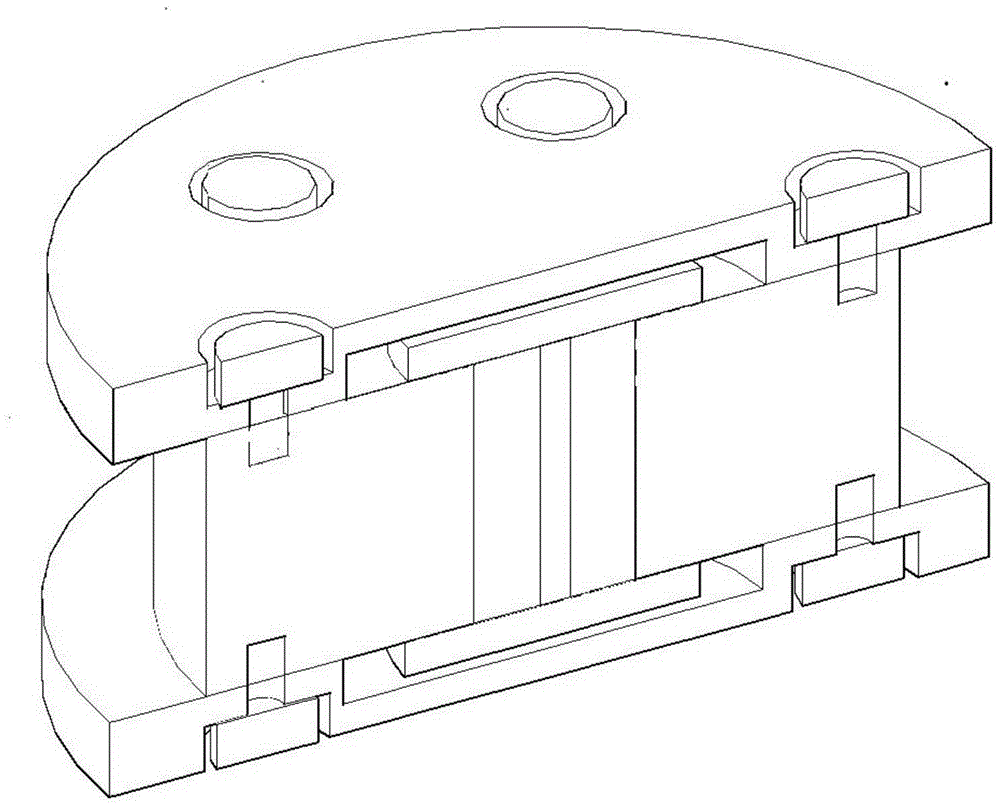

[0028] figure 2 It is a schematic diagram of the section view of the pullout-resistant high-damping rubber shock-isolation bearing. Such as figure 2 As shown, the anti-drawing high-damping rubber shock-isolation bearing includes an upper bearing plate, an upper sealing plate, a high-damping rubber bearing body, a lower sealing plate, a lower connecting plate, a drawing-resistant connecting body 4 and bolts 5. Wherein the upper and lower connecting plates and the upper and lower sealing plates are provided with bolt holes.

[0029] Bolt holes are pre-processed on the upper and lower sealing plates and the high damping rubber bearing body 3 is integrally vulcanized together, and the pullout-resistant connecting body 4 is welded on site. First, the lower rigid disc and the middle steel rod are welded together, and the middle steel rod The hole reserved in the middle of the high-damping rubber bearing body passes through the vulcanized whole of 2 and 3, and the pull-out-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com