Device capable of measuring limited filling pressure and displacement produced when retaining wall rotates around wall bottom

A technology that rotates around the bottom of the wall and retains the wall. It is used in the testing of basic structures, buildings, artificial islands, etc. It can solve the problem of little model test research, and achieve the effect of simple structure, convenient operation and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

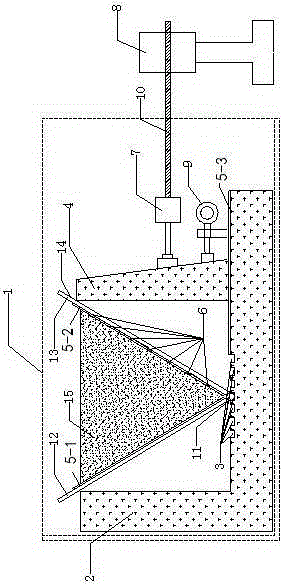

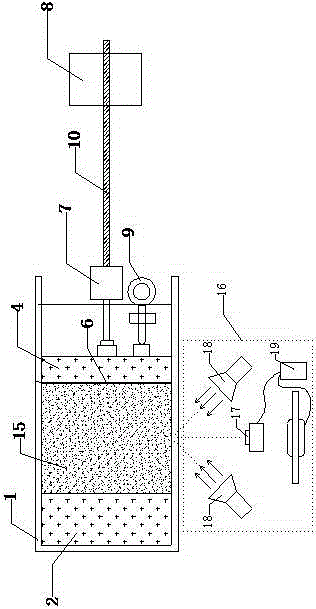

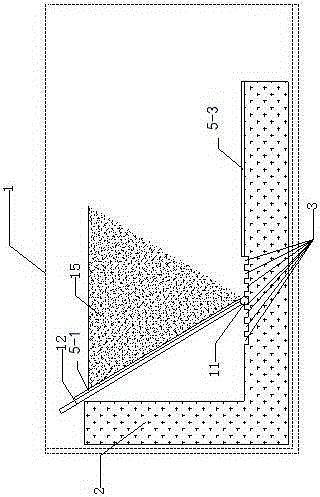

[0024] Embodiment 1: its front and rear sides of transparent plexiglass model box 1 are 500mm long and 400mm wide, and the left side is 400mm long and 200mm wide, and the bottom surface is 500mm long and 200mm wide, and the plexiglass plate thickness is 10mm; L The glyph concrete pouring block 2 has a length of 530mm, a width of 200mm, a height of 380mm, and a thickness of 80mm; a sawtooth groove 3, a depth of 5mm, a length of 200mm, a width of 15mm, and an interval of 10mm; the retaining wall 4, the wall height is 300mm, the upper bottom is 40mm, the lower bottom is 80mm, and the width is 200mm; the length of the first steel plate 12 and the second steel plate 13 are both 500mm, the width is 200mm, and the thickness is 5mm.

[0025] Put a layer of sandpaper on the inner side of the retaining wall, the steel plate and the bottom plate to ensure that the friction of the soil is consistent with the friction of the sandpaper, so as to eliminate the influence of the boundary on the...

Embodiment 2

[0037] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special feature is that the inclination angle of the slopes on both sides of the limited fill is changed, that is, by placing the hinges 11 in different sawtooth grooves 3, changing the first steel plate 12 and the angle between the second steel plate 13 to achieve. It can be used to study the influence of different limited fill slope angles on soil pressure and displacement when the retaining wall rotates around the bottom of the wall.

Embodiment 3

[0038] Embodiment 3: This embodiment is basically the same as the preceding embodiment, and the special feature is that the direction in which the second steel plate 13 rotates around the bottom of the wall is changed, even if the SDJ-1 type three-speed electric and other strain control shearing instruments 8 rotate around the wall to the left The bottom rotation can be used to study the change law of the soil pressure and displacement when the limited fill soil is passively damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com